Silicone Heat Tape is a highly efficient heating device used in industrial and laboratory scenarios, among others. It is made of high-temperature resistant silicone and has a wide temperature range (-60°C to +230°C) to adapt to extreme environments. The band is embedded with uniformly distributed resistance wires for fast and even heat transfer. It is flexible and can be flexibly wrapped around various shapes of equipment surfaces (e.g. pipes and containers) and is waterproof and dustproof (IPX6), suitable for humid or dusty environments. It is suitable for a wide range of applications in scientific research, industrial equipment insulation, pipeline frost protection and agricultural temperature control.

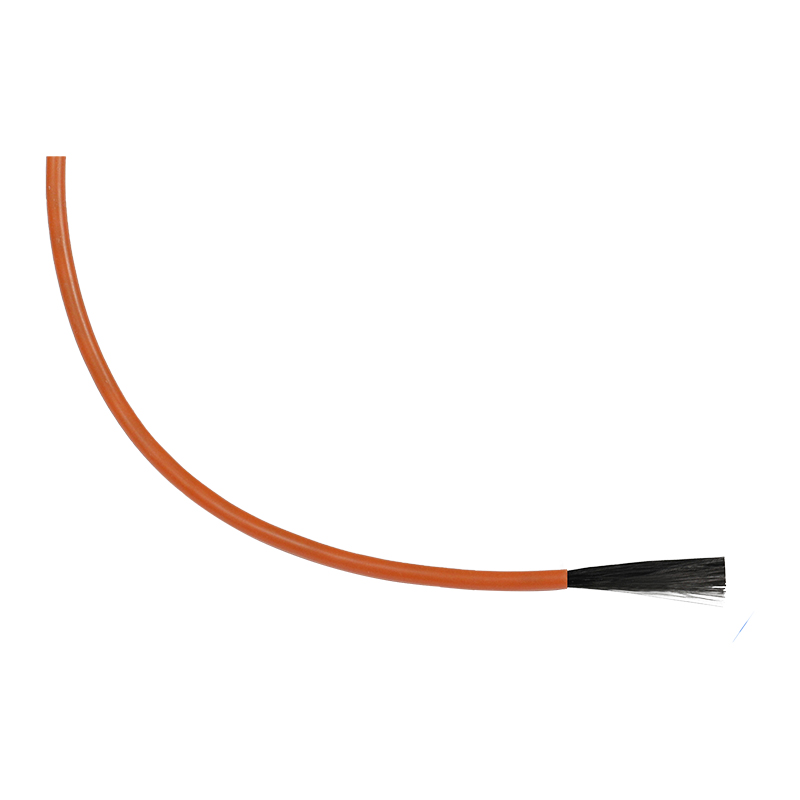

Silicone Heat Tape, also known as Silicone Heating Tape, is a flexible heating tape specifically designed to provide even, continuous heating. It is made of silicone material with the characteristics of high temperature resistance, waterproof, good flexibility, etc. It is widely used in industry, scientific research, electronics, pipeline heating, medical and other fields.

Product features

1. High temperature resistance: Silicone Heat Tape can usually withstand temperatures ranging from -60°C to +230°C, and can even withstand higher temperatures, stable performance in high temperature environments.

2. Uniform Heating: The embedded heating line is designed to be uniform, ensuring even heat distribution and avoiding localized overheating, suitable for heating precision equipment and sensitive materials.

3. Rapid warming: Heating tape is designed with low heat capacity to respond quickly and provide heating without affecting production efficiency.

4. High flexibility: Silicone material is highly flexible and can be bent or wrapped around different shapes of surfaces at will, such as round pipes and valves.

5. Waterproof and dustproof: The silicone shell has good waterproof and dustproof performance (IPX6 and above grade), suitable for wet or dusty working environment.

6. Energy-saving and environmental protection: power control is adjustable to reduce energy consumption, and the silicone material is environmentally friendly, non-polluting, and meets environmental standards.

Common specification parameters

1. Voltage range: usually support a variety of voltage options such as 110V, 220V, 240V, etc., to adapt to different countries and industrial needs.

2. Power range: optional power ranges from 10W to 1000W, depending on application scenarios and temperature requirements.

3. Temperature control: it can be equipped with thermostatic controller to regulate the accuracy of the temperature, which is suitable for the heating needs of different materials.

4. Bandwidth and length: the width is generally 25mm, 50mm, the length from 0.5m to 10m optional, customized according to the application needs.

5. Thickness of material: the thickness of heating tape is generally 1.5mm to 3.0mm, with a certain degree of abrasion resistance, to increase the service life.

Working Principle

Silicone Heat Tape heats up the internal resistance wire through electric current, and is wrapped with silicone material as the insulating layer. When the electric current passes through the resistance wire, heat will be generated and evenly transferred to the surface of the heated object through the silicone layer, realizing continuous and stable heat output. The power density of heating tape is moderate, usually equipped with a temperature controller for precise temperature control, to adapt to the heating needs of different applications.

Main applications

1. Industrial pipeline and container heating: used in the chemical industry, petroleum and other industries to heat and maintain a constant temperature of the pipeline and container material to avoid freezing or solidification.

2. Laboratory and scientific research heating: used in laboratories to control the temperature of heating equipment and experimental devices, providing a stable heat source for precision experiments.

3. Equipment and instrument heating: used in semiconductor equipment, electronic instruments, medical equipment, etc. to provide efficient and stable heating solutions.

4. Automotive and aviation heating: widely used in antifreeze heating of automobiles and temperature control of aviation equipment, suitable for use in harsh environments.

5. Family and agricultural applications: such as greenhouse and incubation equipment heating, pipeline anti-freezing, flower maintenance, etc., especially suitable for application scenarios that require flexible heating.

Usage

1. Installation: Wrap the heating tape around the surface to be heated (e.g. pipes or containers), which can be fixed with strapping tape or adhesive tape.

2. Connect the power supply: in accordance with the voltage requirements of the heating tape into the corresponding power supply, to ensure that the wiring is correct.

3. Temperature adjustment: can be equipped with a temperature controller for precise temperature control, to ensure that the operation in the appropriate temperature range.

4. Safety check: check all the connection points before energizing to make sure there is no risk of loosening or leakage to ensure safe operation.

Product Advantage

1. High heating efficiency: As Silicone Heat Tape closely fits the heating surface, it can conduct heat more efficiently and save energy.

2. Easy to install and dismantle: The flexible structure is easy to install and reusable, suitable for equipment that needs to be heated and dismantled frequently.

3. Strong adaptability: it can work normally in both low and high temperature environments and is widely used in extreme working environments.

4. Low maintenance cost: Due to the durable silicone material, it reduces the risk of wear and corrosion, and extends the service life of the equipment.

What is the working principle of Silicone Heat Tape?

Silicone Heat Tape generates heat by flowing electric current through the embedded resistance wire, and the heat is evenly transferred to the surface of the heated object through the silicone layer to achieve stable heat output.

What is the temperature range of Silicone Heat Tape?

Typically, Silicone Heat Tape has a temperature range of -60°C to +230°C. Some products may be able to withstand higher temperatures, depending on the product specification.

What applications can Silicone Heat Tape be used in?

Silicone Heat Tape is widely used in industrial equipment, laboratory heating, pipe and container frost protection, electronic equipment insulation and greenhouse planting heating.

Is Silicone Heat Tape waterproof?

Yes, most Silicone Heat Tape is waterproof (usually up to IPX6 rating) and is suitable for use in wet environments, but prolonged immersion under water is not recommended.

Can Silicone Heat Tape be cut?

No. Silicone Heat Tape contains resistance wires and cutting it will damage the circuitry and prevent the heat tape from working properly.

Can Silicone Heat Tape be continuously heated for a long time?

Yes, Silicone Heat Tape is designed to be durable and can be heated for long periods of time, but it is recommended that a thermostat be used to prevent overheating and extend the life of the heating tape.

How to fix Silicone Heat Tape?

Silicone Heat Tape is usually secured to the surface of the heated object using strapping tape, silicone tape, etc. to ensure a tight contact to increase heating efficiency.

Does Silicone Heat Tape need a temperature controller?

No. It is recommended to use a temperature controller to accurately regulate the heating temperature to avoid overheating and to adapt to different application requirements.

What is the typical wattage of Silicone Heat Tape?

The power varies from model to model, usually ranging from 10W to 1000W. Choosing the right power needs to take into account the size of the object to be heated and the temperature requirements.

Does Silicone Heat Tape have any safety approvals?

Yes, most Silicone Heat Tape meets CE, UL and other safety approvals, depending on the product model and manufacturer.

Previous: Carbon Fiber Heating Element

Next: Seedling Mat

Contact

No. 1, 1st Road, Mawu Industrial Zone, Qiaoli, Changping Town, Dongguan City, Guangdong Province

Email:

Phone:

+86 136-2001-9955

+86-0769-83488762-8016