Flexible Silicone Heater is widely used in medical devices, laboratory analyzers, industrial equipment, military and aerospace, and many other applications due to its unique flexible design, efficient heating, safety, reliability, durability, and customizability. When selecting and using them, be sure to select and configure them for your actual needs and follow the guidelines and recommendations provided by the manufacturer to ensure optimal performance and safety.

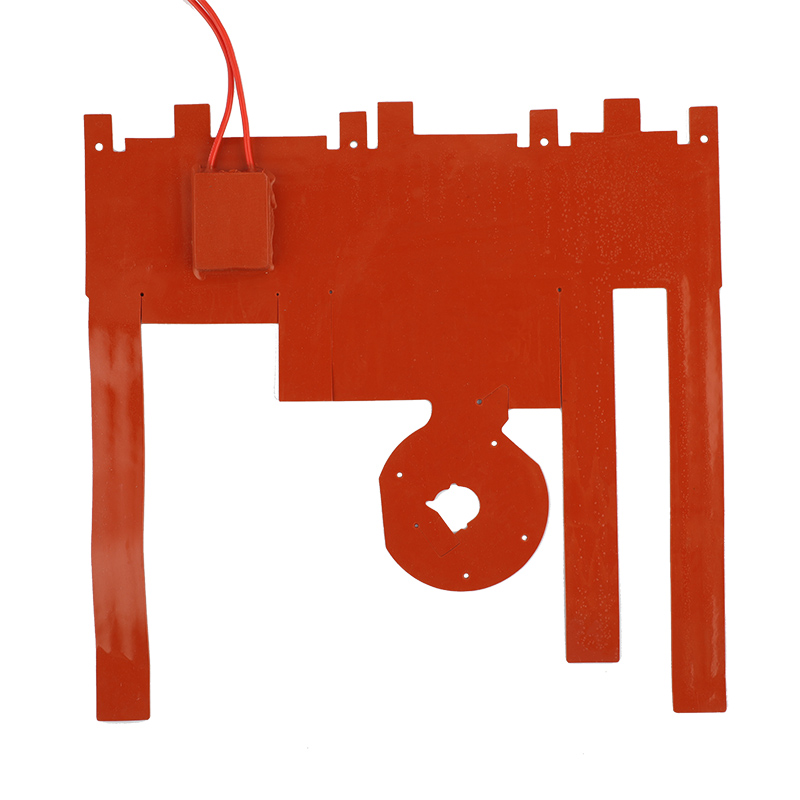

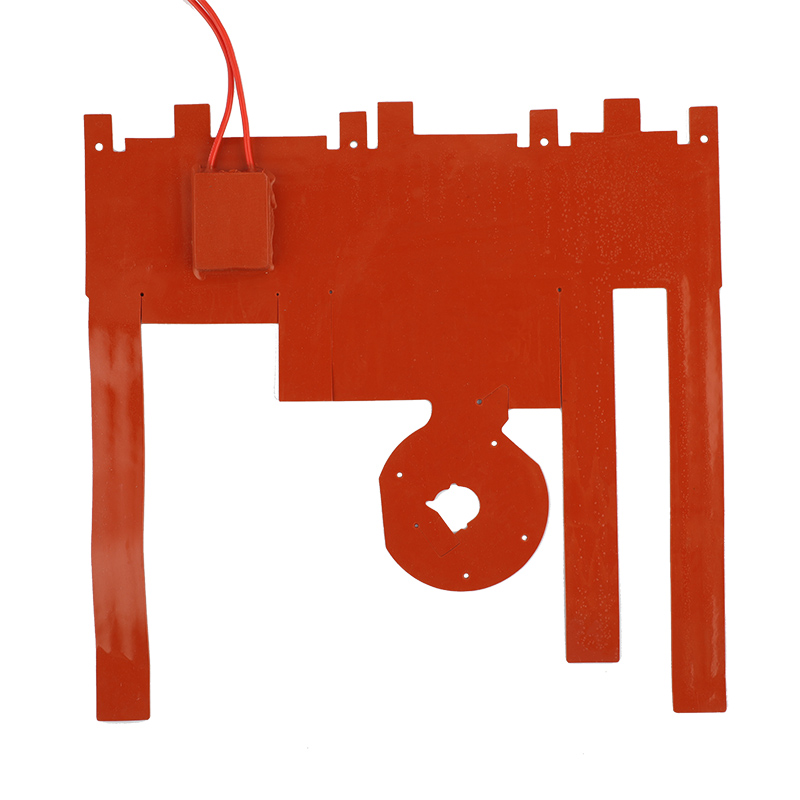

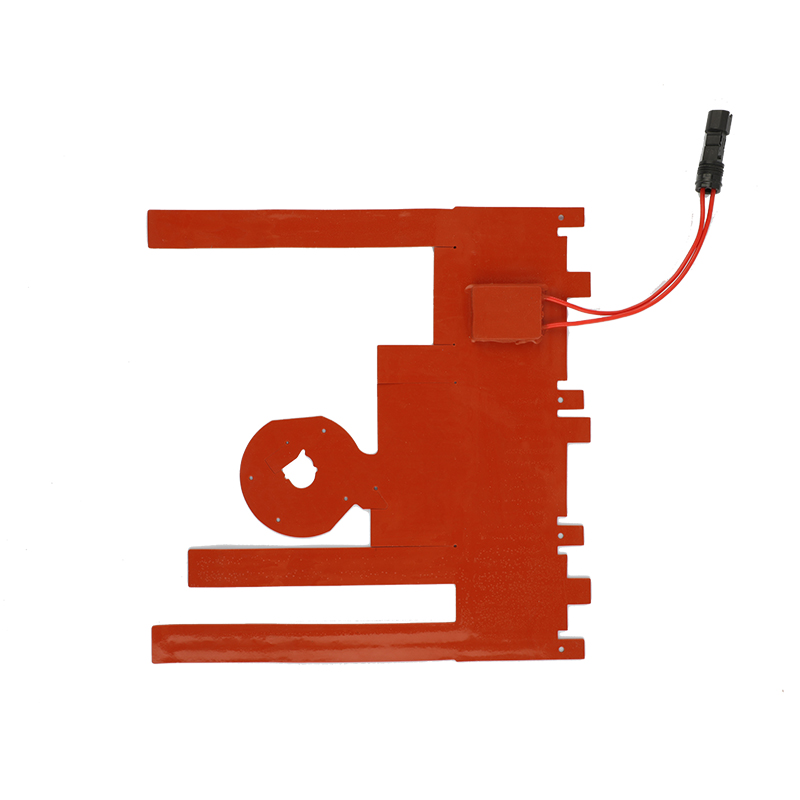

The Flexible Silicone Heater is an advanced heating solution engineered to deliver efficient and consistent thermal performance across a wide range of industrial, medical, and commercial applications. Crafted with durable silicone rubber materials and precision-engineered components, our heaters provide the perfect combination of flexibility, high temperature resistance, and energy efficiency.

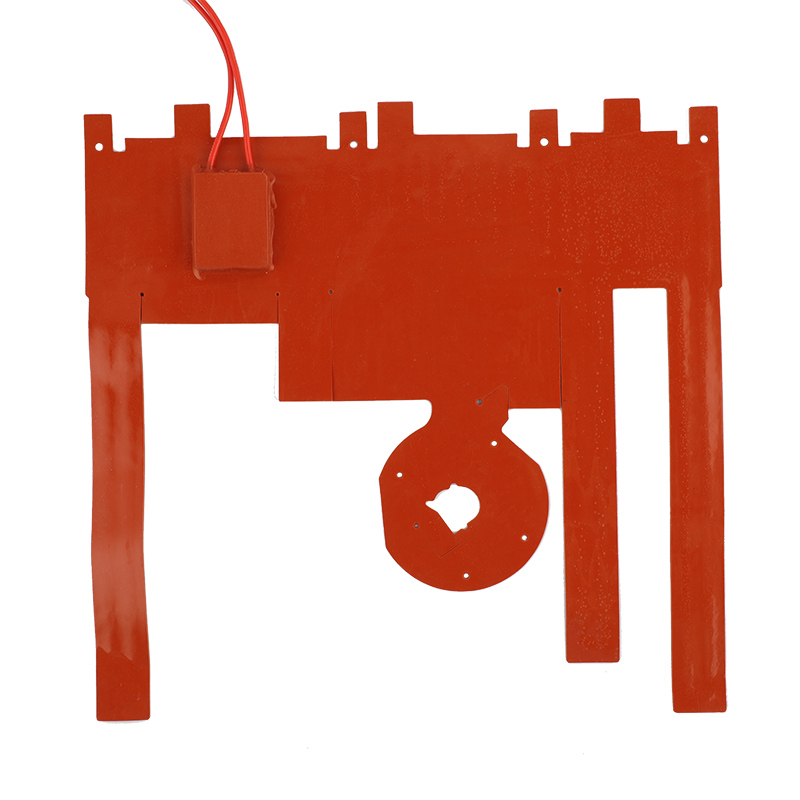

Whether you're looking for a Silicone Rubber Heater for industrial heat tracing, a Silicone Heating Pad for medical devices, or a Rubber Heat Mat for 3D printing platforms, our product line is fully customizable to fit your specific needs.

High Flexibility

The core advantage of a Flexible Silicone Heater is its ability to conform to curved, contoured, or irregular surfaces. This makes it ideal for heating tanks, pipes, barrels, and complex machinery components.

Durable Silicone Rubber Material

Our Silicone Rubber Heaters are constructed from high-quality, fiberglass-reinforced silicone rubber, providing outstanding resistance to heat (up to 230°C), chemicals, and moisture.

Uniform Heat Distribution

Whether it’s a Silicone Heat Mat or Silicone Heating Pad, our heaters ensure even thermal output across the surface, reducing hotspots and improving process reliability.

Quick Heat-Up Time

With an efficient internal heating element, each Silicone Rubber Heater reaches operating temperature quickly, helping improve energy savings and system response time.

Custom Configurations Available

From a compact Rubber Heat Mat to large-area Silicone Heat Mats, we offer tailor-made sizes, voltages (12V/24V/110V/220V), watt densities, and mounting options to match your exact requirements.

Industrial Equipment & Process Heating

Ideal for freeze protection and temperature maintenance in machinery, valves, tanks, and pipes. Silicone Rubber Heaters are widely used for pipe heat tracing and condensation control.

Medical and Laboratory Devices

Silicone Heating Pads provide safe and consistent heating for sterilization equipment, incubators, diagnostic tools, and lab sample warmers.

3D Printing Platforms

Silicone Heat Mats deliver stable and even heating to print beds, improving print adhesion and overall print quality.

Aerospace & Automotive Heating

Used to prevent freezing or maintain optimal conditions in fuel cells, battery packs, and sensitive instrumentation.

Food Equipment

Maintains ideal temperatures for food storage, delivery systems, or preparation surfaces.

Lightweight Yet Robust: Easy to install and reposition without compromising strength.

Moisture-Resistant: Perfect for outdoor or humid environments thanks to the sealed silicone structure.

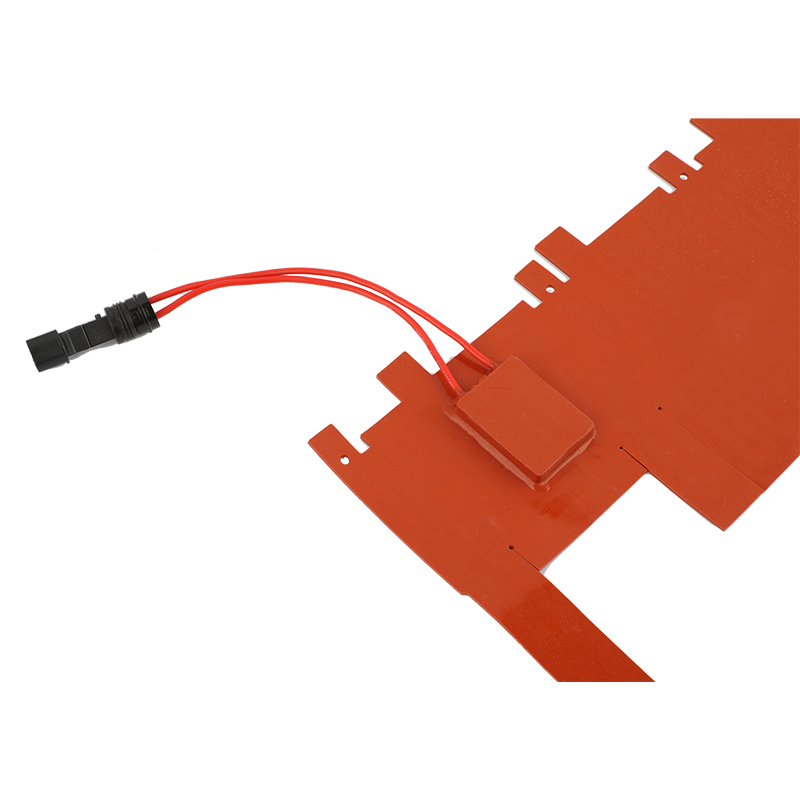

Flexible Power Options: Can be built with thermostats, sensors, and temperature control systems.

Eco-Friendly: Energy-efficient operation leads to lower power consumption and reduced operational cost.

Safe Operation: All Silicone Heat Mats are tested for thermal stability, electrical safety, and mechanical reliability.

Direct Manufacturer Pricing – No middlemen, no markup.

Custom OEM/ODM Available – Tailor your Silicone Rubber Heater with your logo, sensor integration, and packaging.

Strict Quality Control – All Silicone Heating Pads undergo rigorous testing for durability and consistency.

Fast Turnaround – Rapid production and delivery, even for custom orders.

Silicone Heating Pad

Flexible Silicone Heater Strip

Silicone Rubber Heater with Adhesive Backing

Waterproof Silicone Heat Mat

Custom Rubber Heat Mat with Digital Thermostat

Flexible Silicone Heaters for Battery Packs or Enclosures

Whether you need a Silicone Heat Mat for machinery or a Silicone Rubber Heater for specialized medical or industrial use, our team is here to help. Contact us today for a custom quote or technical consultation.

Flexible | Durable | Efficient | Customizable

Q1: What materials are used in your custom long sleeve fishing shirts?

A1: Our shirts are primarily made from high-performance polyester or polyester-spandex blends, ensuring moisture-wicking, quick-dry, lightweight, and breathable properties ideal for fishing and outdoor activities.

Q2: Can I print my company or team logo on the fishing shirts?

A2: Yes, we offer full customization, including logo printing, team names, slogans, and even personal names or numbers. Sublimation and screen printing options are available.

Q3: Are your custom fishing shirts UV-protective?

A3: Absolutely. Most of our custom long sleeve fishing shirts come with UPF 50+ sun protection to guard against harmful UV rays during long hours outdoors.

Q4: What sizes do you offer?

A4: We offer a full size range from XS to 5XL in unisex standard fit. Size customization is also available for bulk orders.

Q5: What is the minimum order quantity (MOQ)?

A5: Our typical MOQ is 10 pieces per design. However, we can accommodate smaller orders depending on the printing method and customization requirements.

Q6: How long is the production time for custom orders?

A6: Production usually takes 7–15 business days after design approval. Shipping time varies depending on the destination.

Q7: Are your fishing shirts suitable for saltwater environments?

A7: Yes, our shirts are designed to withstand harsh saltwater conditions. They are durable, colorfast, and resistant to fading.

Q8: Can I choose different designs for front and back?

A8: Yes, we support full customization on all sides of the shirt. You can upload your artwork or work with our designers to create a unique look.

What are the main components of the Flexible Silicone Heater?

The main components of the Flexible Silicone Heater include a Nichrome wire, silicone rubber insulation and (optionally) a self-adhesive layer. The wire generates heat, the silicone rubber insulation provides electrical isolation and thermal protection, and the self-adhesive layer facilitates installation.

What are the key features of Flexible Silicone Heater?

The key features of Flexible Silicone Heater include flexible design, efficient heating, safety and reliability, durability and customizability. These features allow the heater to adapt to a variety of shapes and sizes of heated objects, provide consistent heating results, and last a long time in harsh environments.

What are the application areas of Flexible Silicone Heater?

Flexible Silicone Heater is widely used in medical devices, laboratory analyzers, industrial equipment, military and aerospace, and many other applications. For example, it can be used for blood analyzers, test tube heaters, industrial pipe insulation, and aircraft instrumentation freeze protection.

How to choose the right Flexible Silicone Heater?

Choosing the right Flexible Silicone Heater requires consideration of a number of factors, including the heater's size, shape, power, voltage, and operating environment. In addition, factors such as the heater's safety, durability and manufacturer's reputation need to be considered.

How is the power and voltage of a Flexible Silicone Heater determined?

The power and voltage of a Flexible Silicone Heater are usually determined by the size of the object to be heated, the desired heating temperature, and the operating environment. When selecting, you need to make sure that the power and voltage of the heater match the power supply to avoid overload or underload operation.

What is the working temperature range of Flexible Silicone Heater?

The operating temperature range of Flexible Silicone Heaters is typically between -40°C and 200°C, depending on the insulation material and the type of heater filament. When selecting a heater, you need to make sure that the operating temperature range is appropriate for the application.

How do I install a Flexible Silicone Heater?

The installation of a Flexible Silicone Heater depends on the specific application scenario and the manufacturer's guidelines. Some heaters are equipped with a self-adhesive layer that can be affixed directly to the object being heated; others may require screws or other fixtures for installation. Always follow the guidelines and recommendations provided by the manufacturer when installing.

What are the maintenance precautions for Flexible Silicone Heater?

When maintaining your Flexible Silicone Heater, there are a few things to keep in mind: check the surface of the heater periodically to make sure it is clean and undamaged; avoid using sharp or hard objects to scratch the surface of the heater; follow the guidelines and recommendations provided by the manufacturer when removing or reinstalling the heater; and make sure that the heater is used in a well-ventilated environment.

What is the life expectancy of a Flexible Silicone Heater?

The life expectancy of a Flexible Silicone Heater depends on a number of factors, including the environment in which it is used, the operating conditions, and how well it is maintained. Under normal use and maintenance, the life of a heater is usually several years. However, the exact life expectancy needs to be evaluated based on the actual application.

What if the Flexible Silicone Heater fails?

If the Flexible Silicone Heater fails, first stop using it immediately and disconnect it from the power source. Then, follow the guidelines and recommendations provided by the manufacturer for inspection and repair. If you are unable to solve the problem by yourself, it is recommended that you contact the manufacturer or a professional repairer to handle the problem. During the handling process, please make sure to ensure safety and follow the relevant operating procedures.

Previous: Electric Tube Heater

Next: PTC Heating Element

Contact

No. 1, 1st Road, Mawu Industrial Zone, Qiaoli, Changping Town, Dongguan City, Guangdong Province

Email:

Phone:

+86 136-2001-9955

+86-0769-83488762-8016