Silicone Rubber Heaters are versatile, flexible, and durable heating solutions for a wide range of applications. Whether for industrial equipment, medical devices, or automotive applications, these heaters provide reliable, even heat distribution while maintaining flexibility and durability. Their ability to be customized for specific shapes, sizes, and power requirements ensures that they can meet the needs of diverse industries and environments.

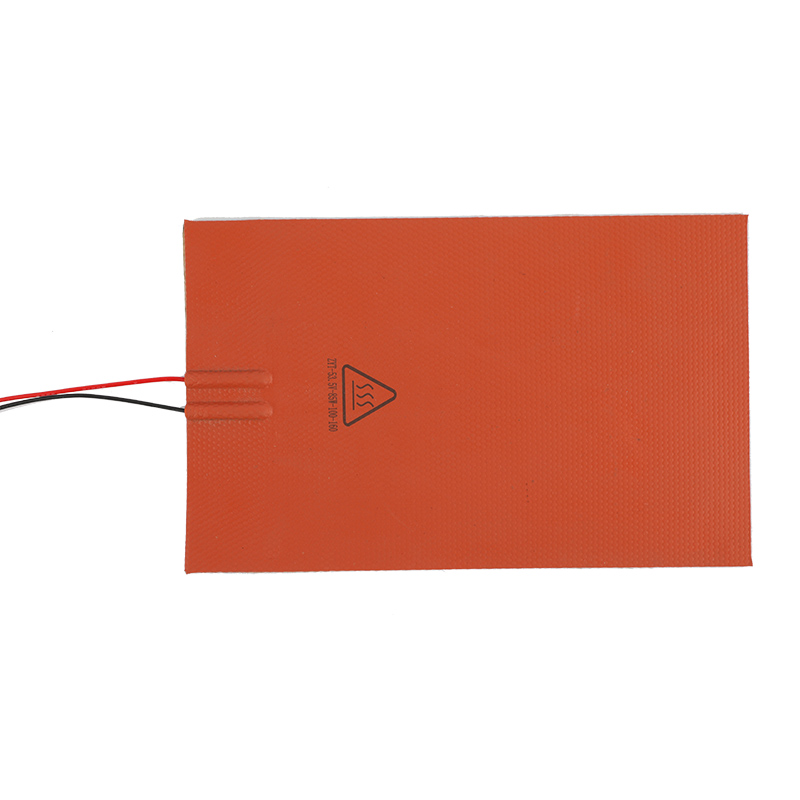

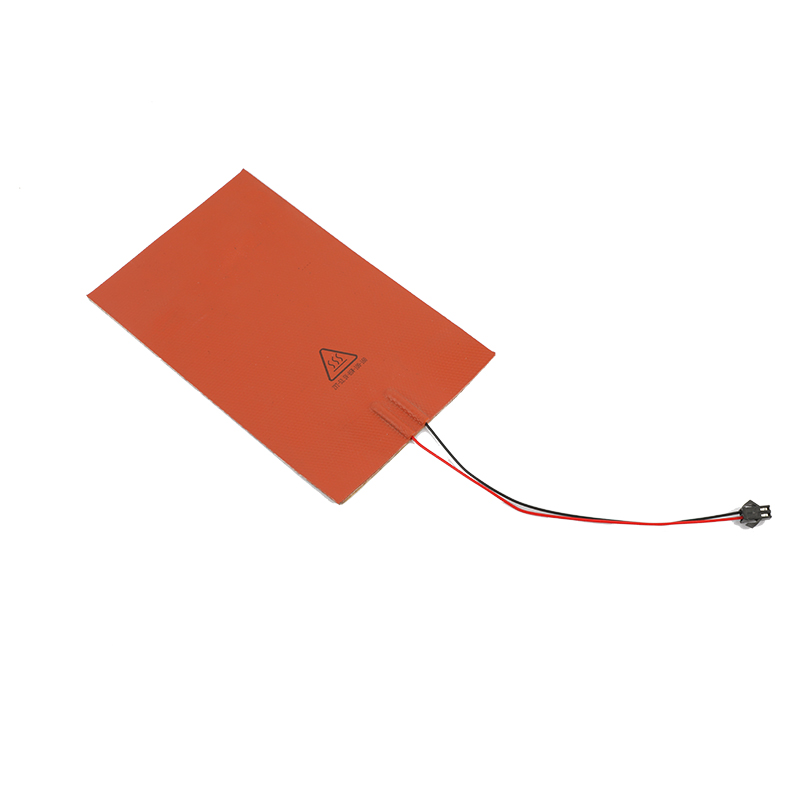

A Silicone Rubber Heater is a flexible heating solution that utilizes silicone rubber as the outer insulation layer, with embedded resistance circuits or metal heating wires inside. This heater type is renowned for its flexibility, durability, and effective heat distribution, making it an ideal choice for industries requiring precise temperature control, such as aerospace, medical, and automotive sectors. Other forms of heating Elements within the same category include Silicone Heat Tape、Rubber Heat Mats、Silicone Heating Pad、Silicone Heat Mat, which offer similar flexibility and durability but are designed for specific applications.

The Silicone Rubber Heater consists of the following critical components:

Silicone Rubber Outer Layer: Known for its heat resistance, flexibility, and durability, the silicone rubber layer withstands high temperatures up to 230°C and maintains its integrity in harsh environments.

Heating Element: Embedded within the silicone rubber are resistance wires or etched metal circuits that provide consistent and even heat distribution. This makes it comparable to Silicone Heat Tape, which is used in applications where the heater needs to be wrapped around objects.

Adhesive Layer (Optional): Certain models come with a self-adhesive backing for easy installation, ensuring the heater maintains close contact with the surface for efficient heat transfer.

Flexibility and Durability: Similar to Silicone Heat Tape and Rubber Heat Mats, silicone rubber heaters are designed to be flexible, allowing them to conform to a variety of surfaces, including irregularly shaped equipment. The silicone material ensures long-lasting performance even in extreme conditions.

High-Temperature Resistance: The silicone rubber construction can endure temperatures up to 230°C, making it ideal for demanding environments. This is particularly useful in applications like Rubber Heat Mats, where heat needs to be evenly distributed over a larger surface.

Lightweight and Thin Design: These heaters are incredibly thin, usually 1.5mm to 3mm in thickness, allowing for seamless integration into systems without adding excessive weight or bulk.

Even Heat Distribution: Like Silicone Heat Tape, the etched foil or nickel-chrome resistance wires ensure uniform heat across the heater's surface, eliminating hot spots and providing consistent temperature regulation.

Water and Moisture Resistance: The silicone material is inherently water-resistant, making the heater suitable for moisture-prone environments like refrigeration systems, tank heating, or outdoor applications.

Customizability: Silicone Heaters can be customized in shape, size, voltage, and power density to meet specific requirements. Whether you need a Rubber Heat Mat for a large, flat area or a Silicone Heat Tape for wrapping around pipes, there is a versatile solution for every need.

Operating Temperature Range: -60°C to 230°C.

Voltage Range: Available in 12V, 24V, 110V, 220V, and custom voltages.

Power Density: Power density ranges from 0.1W/cm² to 1.5W/cm², similar to that of Silicone Heat Tape for efficient heating.

Thickness: Standard thickness between 1.5mm and 3mm.

Dielectric Strength: Up to 1500V.

Insulation Resistance: Greater than 100MΩ.

Shape and Size: Custom shapes and sizes to suit any application, from Rubber Heat Mats for flat surfaces to Silicone Heat Tape for wrapping.

Industrial Equipment Heating: Ideal for heating tanks, pipes, and containers, much like Silicone Heat Tape, which wraps around pipes for temperature maintenance.

Food Processing: Used in food warmers, baking equipment, and temperature-sensitive applications.

Aerospace and Military: Silicone Heaters are applied in aircraft instruments and avionics to maintain operational efficiency in extreme cold.

Medical Devices: Commonly used in hospital beds, laboratory incubators, and medical diagnostic equipment.

Automotive Industry: Heaters are utilized in applications such as mirror defrosting, oil tank heating, and battery warmers, with similar applications as Silicone Heat Tape for de-icing.

3D Printing: Ensures platform and print head stability by maintaining the desired temperature.

Communication Equipment: Maintains stable temperatures in outdoor antennas and sensitive electronic components, often utilizing Rubber Heat Mats for larger areas or Silicone Heat Tape for specific components.

Shape and Size: Custom shapes, including flat Rubber Heat Mats or flexible Silicone Heat Tape, are available.

Voltage and Power: Custom voltage and power configurations can be tailored to specific heating needs.

Installation Methods: Heaters can be equipped with self-adhesive backing or designed with mounting holes for easy installation.

Temperature Control: Thermostats, thermocouples, and temperature sensors can be integrated for precise temperature regulation.

Wiring Options: Custom wiring options ensure seamless integration into existing systems.

Silicone heaters, include Silicone Heat Tape、Rubber Heat Mats、Silicone Heating Pad、Silicone Heat Mat, meet international standards such as CE, UL, and RoHS. They are tested for temperature tolerance, dielectric strength, and insulation performance, ensuring reliable and safe operation.

These heaters, include Silicone Heat Tape、Rubber Heat Mats、Silicone Heating Pad、Silicone Heat Mat, are carefully packaged to protect them from environmental factors like moisture and static during shipping.

A Silicone Rubber Heater is a flexible heating device made from a silicone rubber outer layer with embedded heating elements, such as etched foil or resistance wires. It is used for various applications where flexible, reliable, and precise heat is needed.

The main features include high flexibility, durability, lightweight design, excellent heat distribution, water and moisture resistance, and the ability to withstand high temperatures up to 230°C. It can also be customized in terms of shape, size, and power output.

Silicone rubber heaters are widely used in industries such as aerospace, automotive, medical, food processing, and 3D printing. They are also used for industrial equipment heating, temperature-sensitive applications, and de-icing purposes.

Silicone rubber heaters offer flexibility, allowing them to conform to irregular surfaces, superior heat distribution, lightweight design, and high durability. Unlike rigid heaters, they can be used in tight spaces or on curved surfaces. Additionally, they have excellent temperature resistance and can be easily customized.

The heating element, typically made of resistance wire or etched foil, is embedded within the silicone rubber insulation. When powered by electricity, the resistance in the heating element generates heat, which is transferred through the silicone rubber to the surface or material being heated.

Yes, silicone rubber heaters are water-resistant and moisture-proof, making them suitable for outdoor or humid environments. The silicone outer layer protects the heater from moisture and weather conditions, ensuring safe operation.

They can be installed using different methods such as adhesive backing, mounting holes, or straps. Some models come with built-in adhesives for easy application on surfaces, while others may require custom fixtures or clamps.

Yes, they can be customized in terms of size, shape, voltage, power density, and installation method. Additional options like built-in thermostats, temperature sensors, and wiring configurations are available to meet specific heating requirements.

Silicone rubber heaters can operate at various voltages, including 12V, 24V, 110V, and 220V, depending on the application. The power output or wattage can also be customized based on the heating needs, with power densities ranging from 0.1W/cm² to 1.5W/cm².

Yes, they are designed to meet international safety standards such as CE, UL, and RoHS. Their dielectric strength and insulation resistance ensure electrical safety, while their durability and moisture resistance reduce the risk of malfunction in harsh environments.

Previous: Rubber Heat Mat

Contact

No. 1, 1st Road, Mawu Industrial Zone, Qiaoli, Changping Town, Dongguan City, Guangdong Province

Email:

Phone:

+86 136-2001-9955

+86-0769-83488762-8016