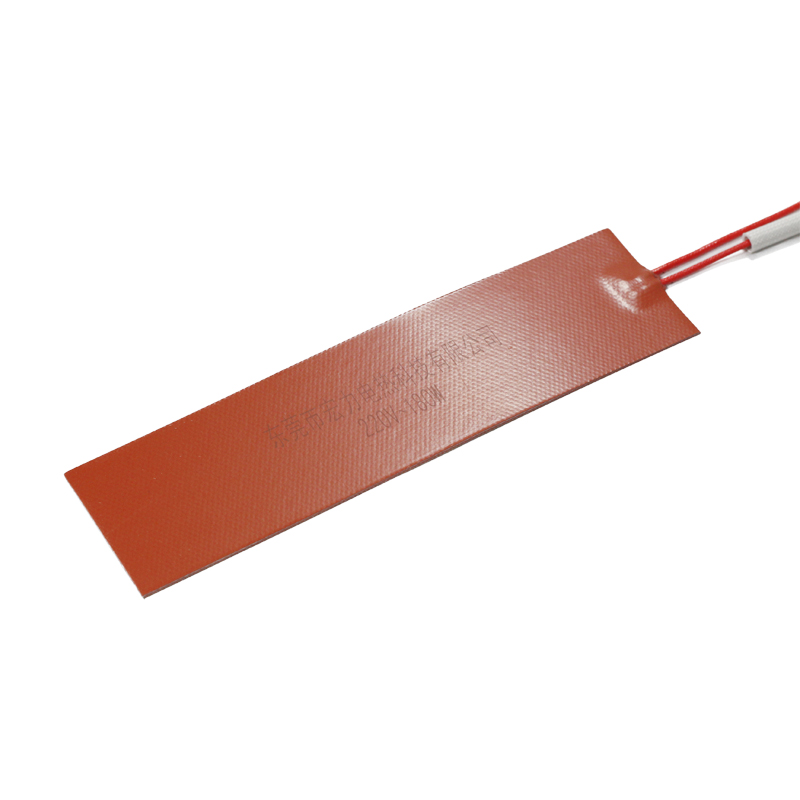

Silicone Heating Pad is a kind of electric heating element made of high temperature resistant silicone rubber, which has the characteristics of softness, pressure resistance and abrasion resistance. It can be in close contact with the heated object to realize fast and even heating, and is suitable for industrial heat preservation, medical equipment heating and many other scenarios. Its wide range of temperature resistance, safety and reliability make it an ideal electric heating solution.

Silicone heating pads are flexible heating elements made of high-temperature resistant silicone material and embedded resistance circuits, which are widely used in scenarios that require uniform heating and temperature control. Due to its flexibility, high temperature resistance, corrosion resistance and efficient heating characteristics, silicone heating pads have important applications in industry, medical equipment, household appliances and many other fields.

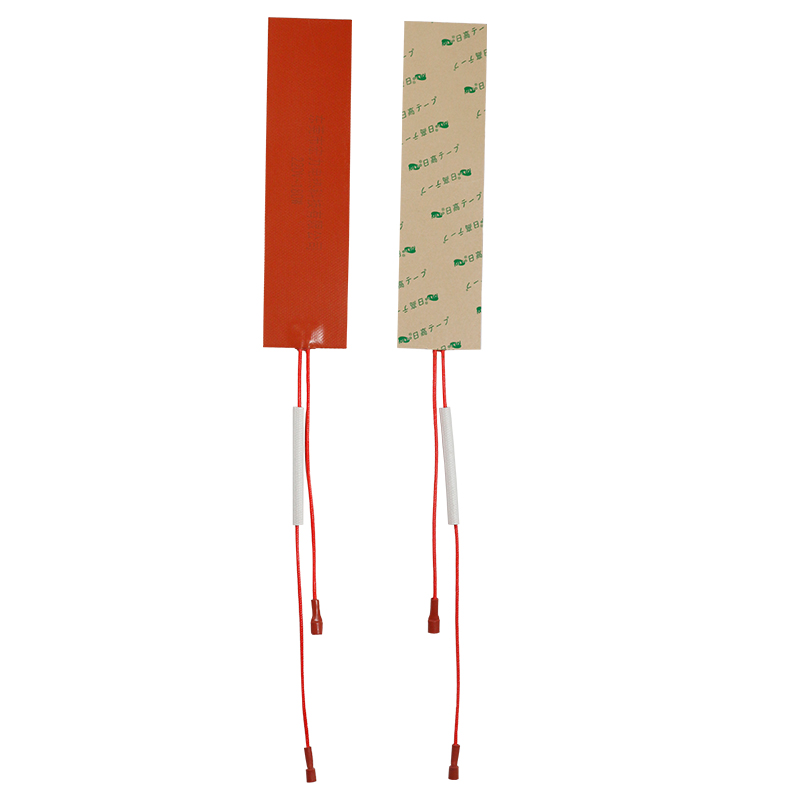

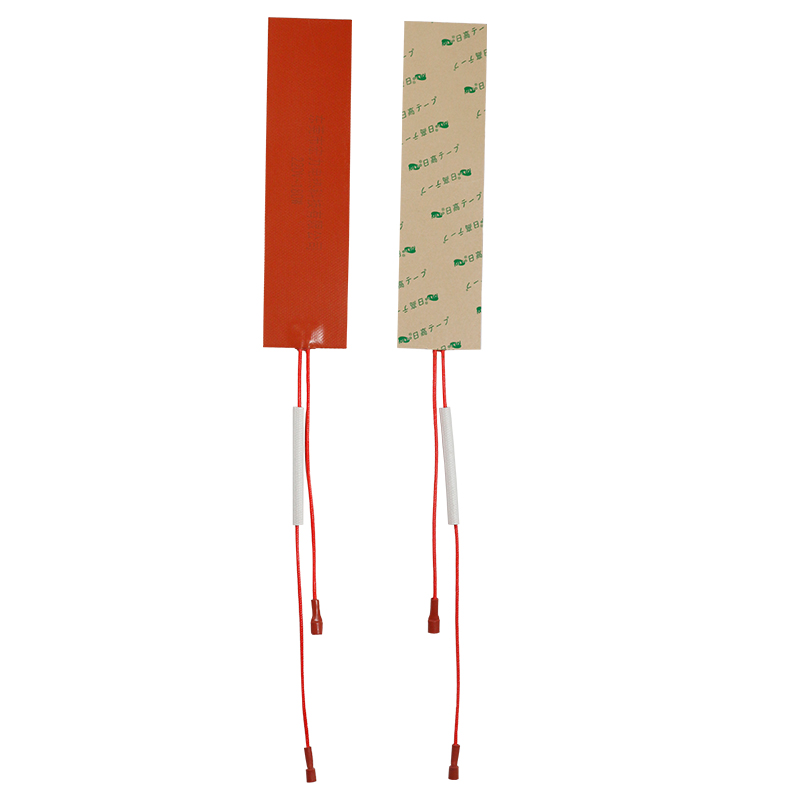

Product structure

The basic structure of silicone heating pad contains three parts:

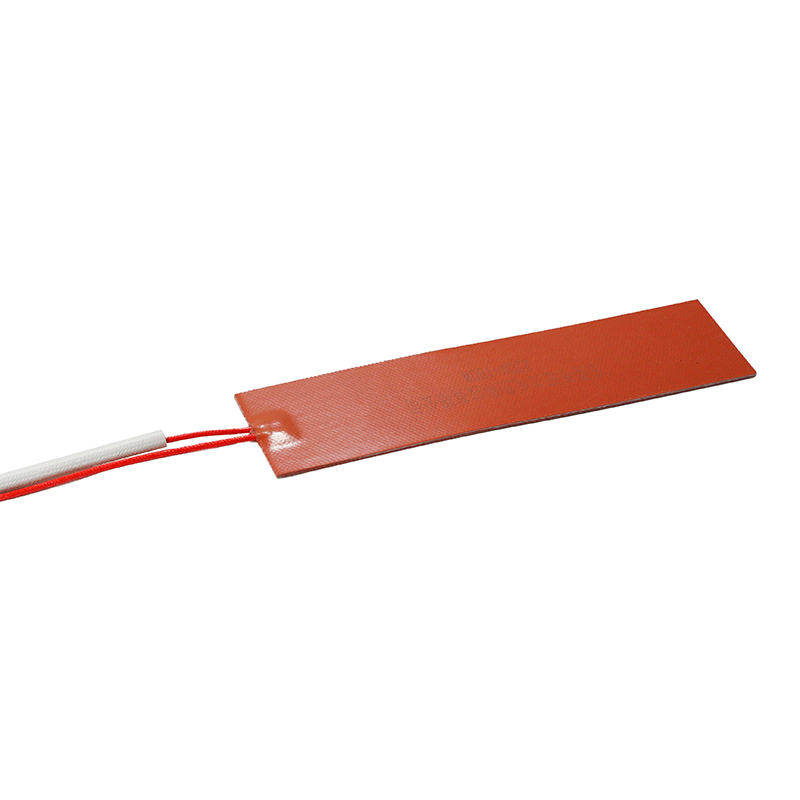

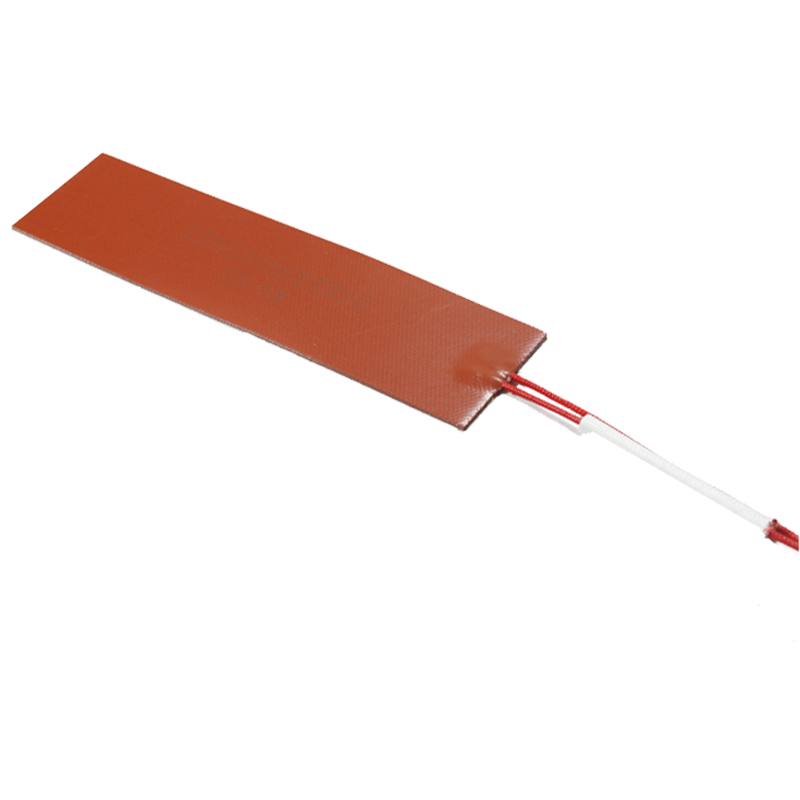

1. Silicone outer layer:the outer layer of the heating pad is made of silicone rubber material, which has good flexibility, heat resistance and electrical insulation properties. Silicone rubber can withstand a wide range of temperatures (-60°C to 200°C) and is well adapted for installation on a variety of complex surfaces.

2. Heating circuits:consisting of metal resistance wires such as nickel-chromium alloy wires, iron-chromium-aluminum alloy wires, or stainless steel wires, which are uniformly distributed inside the silicone rubber mats. Depending on the requirements, these heating circuits can be etched, wound or printed to provide uniform and stable heating effect.

3. Adhesive layer or mounting holes:For ease of installation, silicone heating mats can often be customized with a self-adhesive backing or pre-drilled mounting holes so that they can be easily attached or fixed to a variety of heating surfaces.

Product Features

1. Efficient heating:Silicone heating mats have excellent thermal conductivity, which can quickly and evenly distribute heat to avoid localized overheating or cooling. Its heating response time is fast and can reach the target temperature within minutes.

2. Flexibility and flexibility:the silicone material itself has a high degree of flexibility, making the heating pad can fit irregularly shaped surfaces, suitable for a variety of curved equipment heating needs.

3. High Temperature Resistance:Silicone heating pads are able to operate continuously in temperatures ranging from -60°C to 200°C, making them ideal for heating applications in high temperature environments.

4. Durable:Silicone material is resistant to aging, corrosion, and UV rays, making it suitable for long-term use, especially those applications involving harsh industrial environments.

5. Insulation safety:Silicone has excellent electrical insulation properties, usually withstanding voltage up to 2000V or more, to ensure safety and reliability in a variety of heating applications, reducing the risk of electric shock.

6. Thickness can be customized:the thickness of conventional silicone heating pads is between 1mm and 3mm, but can be adjusted according to specific application requirements, both to maintain the heating effect without affecting the compactness of the equipment.

7. Light weight:Silicone heating pads are lightweight and will not increase the burden on the equipment or take up extra space, which is very suitable for limited space or weight-sensitive scenarios.

Application Areas

1. Industrial equipment heating:Silicone heating mats are widely used in industry, such as heating and insulation of pipes, tanks, containers, etc., to prevent liquids or gases from freezing in low-temperature environments. It can also be used for heating and temperature control of the internal components of the equipment.

2. Medical equipment:In medical equipment, silicone heating pads are commonly used in hospital bed heating, physical therapy equipment, thermostatic appliances, laboratory equipment, etc., to ensure the therapeutic effect through precise temperature control.

3. Food Processing Equipment:Used in food processing equipment for heating and heat preservation, such as coffee machines, baking equipment, hot beverage machines, etc., to ensure that the food or beverage to maintain a constant temperature.

4. Automobile industry:used in automobile engine preheating, automobile seat heating, rearview mirror defrost heating, etc., especially in the cold climate has a significant role.

5. Electronic equipment heating:silicone heating pads can be used in cameras, batteries, monitors and other electronic equipment, to prevent the impact of low temperature on the performance of the equipment, to ensure that the normal operation of the equipment in the cold environment.

6. Aerospace:Silicone heating mats are commonly used in aircraft, satellites and spacecraft in electronic equipment heating, to prevent equipment failure in high altitude or low temperature environment.

7. 3D printers and laboratory equipment:In 3D printers, they are used to heat the printing platform and ensure material stabilization during the printing process; in laboratory equipment, silicone heating pads are commonly used for heating reagents and constant temperature of samples.

Customization Options

1. Voltage and power customization:Heating pads with different voltages and powers can be designed according to specific application requirements to adapt to different heating conditions.

2. Shape and size:Silicone heating pads can be customized in different shapes (e.g., round, square, shaped, etc.) and sizes to fit different equipment or surfaces for installation.

3. Temperature control equipment integration:temperature control elements such as thermostats, thermocouples or thermistors can be integrated to achieve precise temperature control of the heating process.

4. Installation:can be customized with adhesive backing, self-adhesive design, or designed with mounting holes for easy fixing and installation.

| Working voltage range | 1.5V~400V | Maximum temperature | 230℃ (if need backing, please refer to the temperature resistance of double-sided adhesive) |

| Insulation voltage | >2500VAC | Ambient temperature range | -40~230℃ |

| Insulation resistance | >11GΩ@1000VDC | Thickness | 1.1~2.5mm |

| Recommended power density | 0.03~0.6W/cm² | RoHS2.0 | compliant |

| Maximum power density: | customized according to requirements | Terminal pulling force | >80N |

| Service life | 8~15 years | Outlet pulling force | >80N |

What is a Silicone Heating Pad?

A Silicone Heating Pad is a flexible heater made of a silicone material that provides even heat at high temperatures.

How does a Silicone Heating Pad work?

An electric current flows through the heating element through the silicone material, and the good thermal conductivity of the silicone realizes uniform heating.

What are the main advantages of Silicone Heating Pad?

The main advantages include high temperature resistance, flexibility, even heating, and chemical resistance.

How high temperature can Silicone Heating Pad withstand?

Typically, they can withstand high temperatures up to 200°C or more.

What are the applications of Silicone Heating Pad?

They are used in electronic equipment, industrial heating, household applications and the automotive industry.

How do I maintain my Silicone Heating Pad?

Regularly check electrical connections, keep surfaces clean and avoid contact with sharp objects.

What is the chemical resistance of Silicone Heating Pad?

Silicone has good resistance to a wide range of chemicals, but the exact chemical resistance depends on the formulation of the silicone.

What are the advantages of Silicone Heating Pad over other types of heating pads?

Compared to other heating pads, Silicone Heating Pad has better flexibility, high temperature resistance and chemical resistance.

How can I ensure the safe use of Silicone Heating Pad?

Avoid overheating, regularly check the electrical connections of the heating mats and make sure they are used in a safe installation environment.

What is the application of Silicone Heating Pad in automobile?

Used for interior heating and anti-freezing, such as heated seats, heated windows, etc. to improve driving comfort and safety.

Previous: Epoxy Heater

Next: PET Heating Film

Contact

No. 1, 1st Road, Mawu Industrial Zone, Qiaoli, Changping Town, Dongguan City, Guangdong Province

Email:

Phone:

+86 136-2001-9955

+86-0769-83488762-8016