Teflon heaters are an excellent solution for high-temperature, corrosion-resistant, and long-life heating applications across a range of industries, including chemicals, food processing, electronics, pharmaceuticals, and automotive manufacturing.

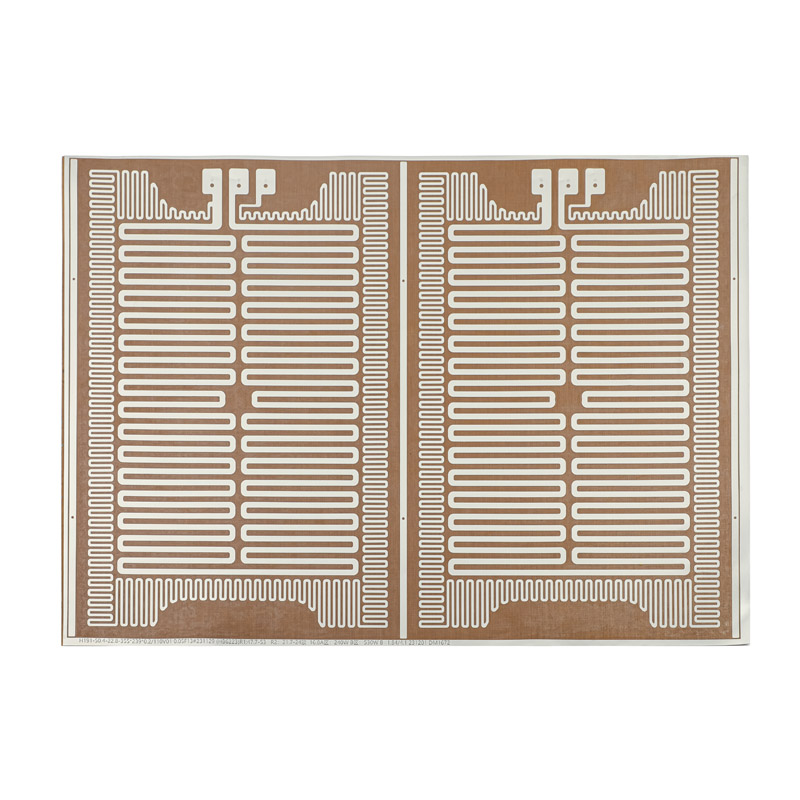

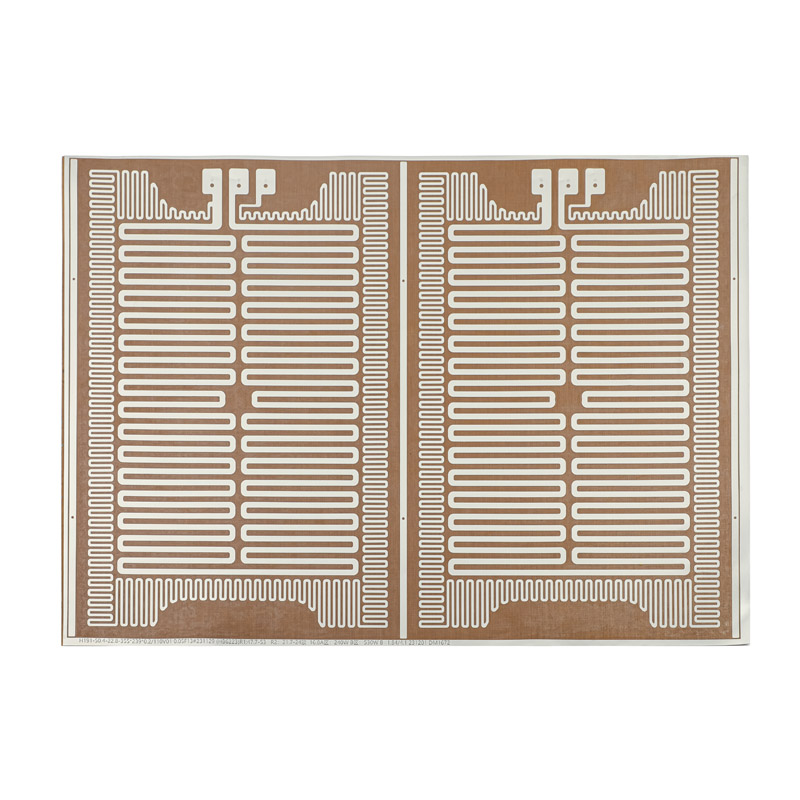

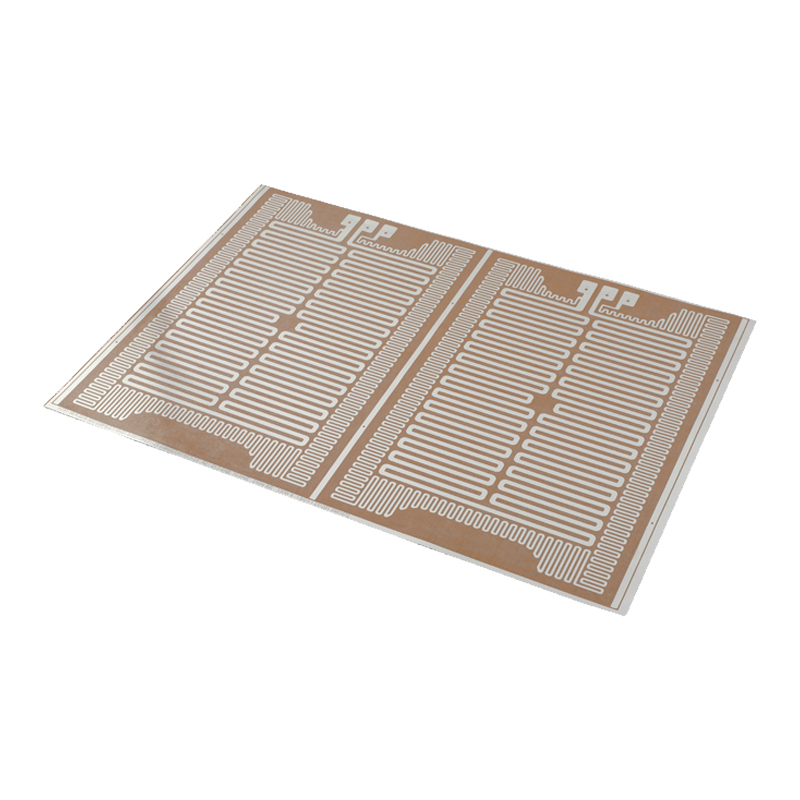

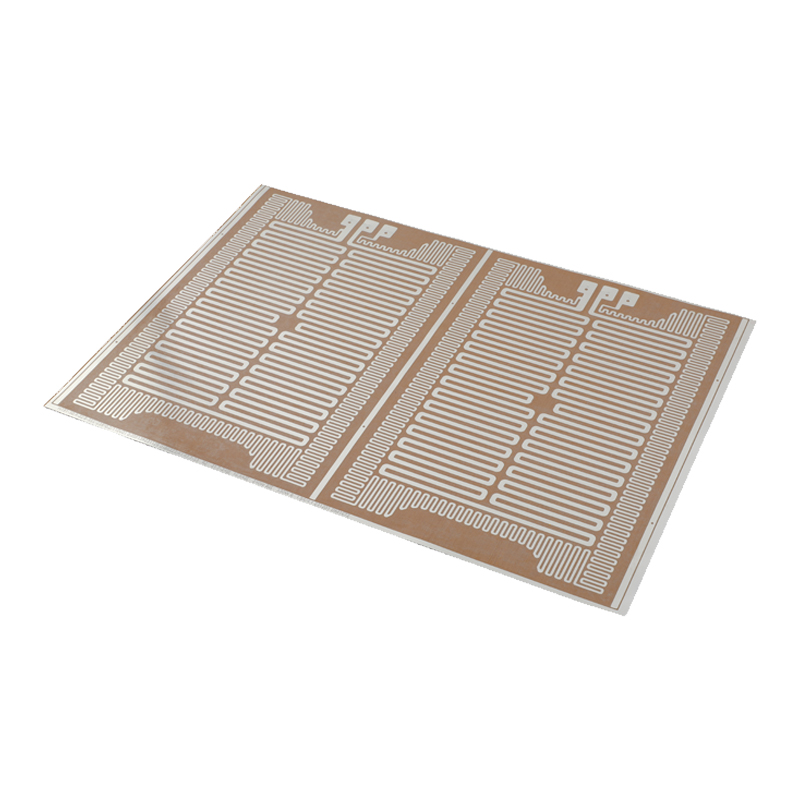

Teflon Heaters are high-performance heating elements made from PTFE (Polytetrafluoroethylene) materials, offering exceptional thermal stability, corrosion resistance, and electrical insulation. These heaters combine the superior chemical stability of Teflon with advanced heating technology, providing efficient and reliable heating solutions for various demanding applications. Below is a detailed introduction to the features, applications, and specifications of Teflon Heaters:

Product Features

1.High-Temperature Resistance

Teflon heaters are capable of operating at extreme temperatures, typically ranging from -200°C to +260°C. Their exceptional thermal stability makes them ideal for high-temperature and cryogenic applications.

2.Corrosion Resistance

Teflon (PTFE) material is highly resistant to a wide range of acids, bases, and solvents. This makes Teflon heaters perfect for use in chemically aggressive environments, where other materials might degrade or corrode.

3.Excellent Electrical Insulation

Teflon heaters provide superior electrical insulation, preventing current leakage and ensuring the safety of both the equipment and operators. This is especially critical for heating applications in electrical and sensitive precision equipment.

4.Low Friction and Self-Cleaning Properties

Teflon’s low friction coefficient reduces wear and tear on the heating element and prevents the accumulation of dirt or debris, extending the heater's lifespan. Additionally, the self-cleaning nature of Teflon makes it suitable for applications requiring high cleanliness standards.

5.Durability and Long Service Life

Teflon heaters are known for their durability, able to withstand long-term use under high loads without degradation in performance. They offer a long service life with minimal maintenance requirements.

| Teflon Heater Technical Specifications | |

|---|---|

| Material | High-purity PTFE (Polytetrafluoroethylene) |

| Operating Temperature Range | -200°C to +260°C |

| Heating Method | Electric heating, forced air heating, etc. |

| Power | Customizable based on specific needs |

| Voltage | 220V, 380V, etc. |

| Structure | Custom designs including tubular, band, and flat forms |

| Insulation Resistance | ≥109 Ω |

Applications

Teflon heaters, including PTFE Heaters and PTFE Heater Film, are widely used in various industries where high resistance to temperature, corrosion, and electrical conductivity is required. Below are some key applications:

1.Chemical Industry

Teflon heaters, especially PTFE heater films, are used in chemical processing equipment, reactors, and pipelines that handle highly corrosive substances. Their resistance to a broad range of acids, bases, and solvents ensures that they remain reliable and efficient in aggressive chemical environments.

2.Food Processing

Due to the non-toxic and food-safe nature of PTFE materials, Teflon heaters are commonly employed in food processing equipment such as drying, sterilizing, and heating systems. PTFE Heater Films are particularly useful in applications where uniform temperature control is required without contaminating the food products.

3.Electronics Manufacturing

PTFE heaters are ideal for heating sensitive electronic components like semiconductors, circuit boards, and high-precision devices. Their ability to maintain stable temperatures without risk of contamination makes them critical in semiconductor processing and other electronics production environments.

4.Pharmaceutical Industry

PTFE heaters are utilized in pharmaceutical manufacturing processes such as mixing, drying, and reaction stages, especially when dealing with volatile or hazardous chemicals. The chemical inertness of PTFE ensures that the materials being processed are not altered or contaminated.

5.Automotive Manufacturing

In automotive applications, PTFE heaters and PTFE Heater Films are used in plastic molding, heat treatment processes, and coating equipment. These heaters' high thermal resistance and durability are perfect for demanding automotive production environments.

6.Medical Equipment

PTFE heaters are found in medical devices that require precise temperature control, such as incubators, autoclaves, and sterilization equipment. The ability to maintain consistent and sterile conditions makes PTFE-based heaters indispensable in healthcare settings.

7.Renewable Energy

PTFE heaters play a significant role in renewable energy systems such as solar power generation, where they are used to regulate temperature in various systems, including thermal storage tanks and photovoltaic panels, ensuring maximum efficiency.

Advantages

1.Superior Temperature Resistance

Teflon heaters, particularly PTFE Heater Films, can withstand extreme temperature fluctuations from -200°C to +260°C, making them perfect for high-temperature applications across various industries. The outstanding heat resistance ensures a long-lasting and reliable performance even under harsh conditions.

2.Chemical Resistance

PTFE heaters are extremely resistant to a wide variety of corrosive chemicals, acids, bases, and solvents. This makes them the ideal choice for use in chemical processing, food processing, and other environments where exposure to aggressive substances is common.

3.Electrical Insulation

PTFE heaters provide excellent electrical insulation, preventing short circuits and ensuring the safety of both the equipment and operators. PTFE Heater Films are often used in sensitive electrical applications due to their high dielectric strength.

4.High Durability and Long Service Life

PTFE heaters have a long operational lifespan thanks to their robust construction and resistance to wear and tear. Their ability to resist high temperatures and corrosive environments without degradation reduces the need for frequent replacements, offering long-term cost efficiency.

5.Uniform Heating

PTFE Heater Films offer a flexible and uniform heat distribution, ensuring consistent temperatures across the entire heating surface. This is especially important in applications requiring precision temperature control, such as electronics manufacturing or pharmaceutical production.

6.Customizable and Versatile Design

Teflon heaters can be tailored to suit a wide variety of applications. PTFE Heater Films, in particular, offer flexible and customizable designs that can be adapted to various shapes and sizes to meet specific needs. Whether it’s a tubular, band, or flat form, PTFE heaters can be designed for a range of applications.

7.Safety and Environmental Benefits

PTFE is non-toxic and environmentally friendly, making it safe for use in food processing, medical, and other sensitive industries. The material’s self-cleaning properties help maintain hygiene and prevent contamination.

8.Low Friction and Self-Cleaning Properties

PTFE heaters have a natural low-friction surface that reduces wear and tear and prevents the accumulation of dirt or residues. The self-cleaning nature of PTFE also makes these heaters ideal for applications in sterile environments.

9.Energy Efficiency

The high thermal conductivity of PTFE Heaters ensures fast and uniform heating, which can lead to energy savings in many industrial applications. Reduced heat loss results in more efficient energy use and lower operational costs.

Previous: Aluminium Electric Heating Plate

Next: Diffuser Heater

Contact

No. 1, 1st Road, Mawu Industrial Zone, Qiaoli, Changping Town, Dongguan City, Guangdong Province

Email:

Phone:

+86 136-2001-9955

+86-0769-83488762-8016