PTFE Teflon Heater is a heater made of PTFE as the main material, with excellent corrosion resistance, high temperature resistance and low friction, it is suitable for heat transfer of many kinds of strong corrosive media, and is widely used in chemical, pharmaceutical and other industries. Its compact structure, high heat transfer efficiency, is the ideal choice for heat transfer of strong corrosive media.

PTFE Teflon Heaters are made of PTFE, a plastic with excellent chemical stability and high temperature resistance.Teflon is a brand name for PTFE, often used to describe the use of this material in different applications.PTFE Teflon Heater is used in high temperature and corrosive environments where precise and uniform heat distribution is required.

Key Properties

1. High temperature resistance:PTFE heaters can work stably in high temperature environments, typically ranging from -200°C to 260°C.

2. Corrosion resistance:PTFE has very high resistance to most chemicals, so it is suitable for chemical processing and corrosive environments.

3. Low coefficient of friction:PTFE has excellent sliding properties and reduces friction loss, making it suitable for use in heating equipment that requires sliding.

4. Insulation performance:PTFE is an excellent insulating material, which helps to prevent current leakage and heat loss, improving safety and efficiency.

Areas of application

1. Chemical and pharmaceutical industries:In these industries, PTFE heaters are used in heating and reaction processes and can withstand strong acids, alkalis and other corrosive substances.

2. Semiconductor industry:Used to heat semiconductor materials to ensure high purity and a pollution-free production environment.

3. Food processing:suitable for food handling and processing due to its high temperature resistance and safety.

4. Plastic processing:Used to heat plastic melts to ensure uniform heating and molding.

Advantages

1. Long service life:Due to the wear and corrosion resistant properties of PTFE, the heaters have a long service life.

2. High efficiency:Uniform heating performance improves overall thermal efficiency and reduces energy waste.

3. Easy maintenance:PTFE heater surface is smooth, not easy to adhere to substances, cleaning and maintenance is more convenient.

Installation and maintenance

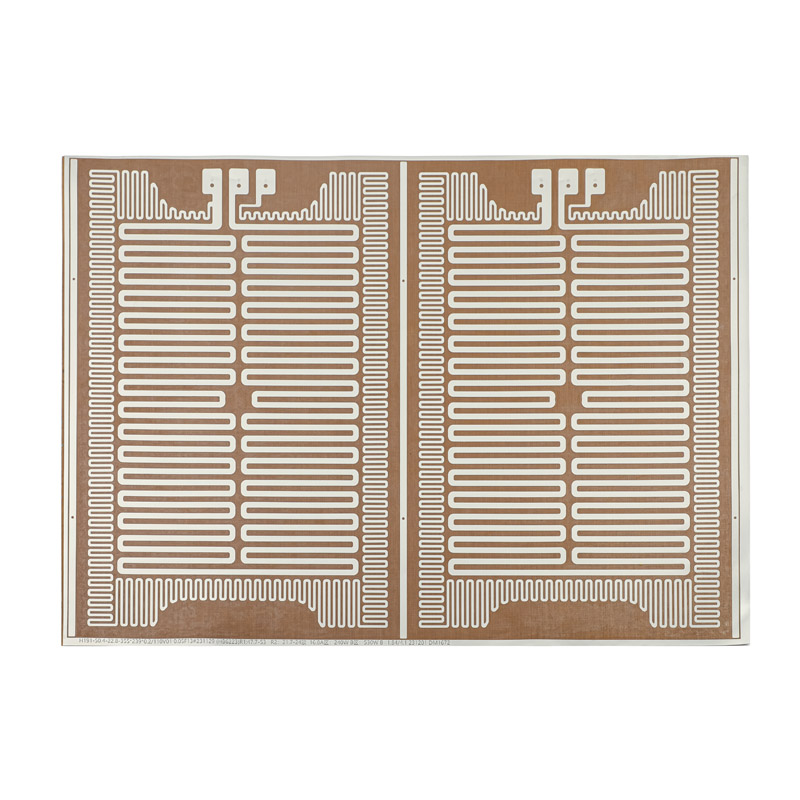

1. Installation:According to the requirements of the equipment, PTFE heaters can be installed in the equipment through bolts, clamps or other fixed means.

2. Maintenance:Regularly check the working condition of the heater to ensure that there is no crack, peeling or other damage. Strong acid and alkali solutions should be avoided when cleaning to avoid damaging the PTFE surface.

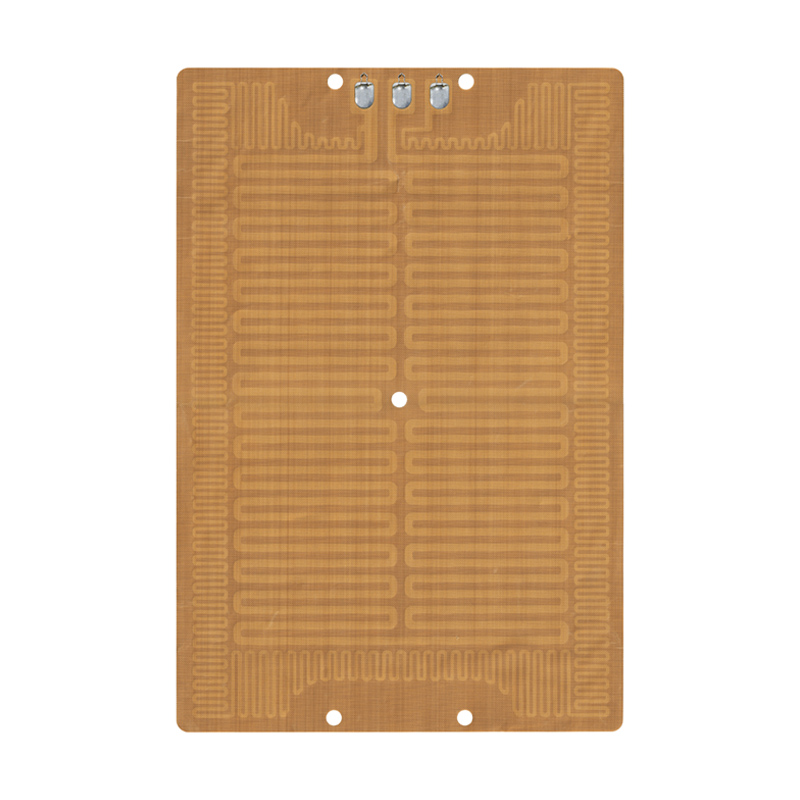

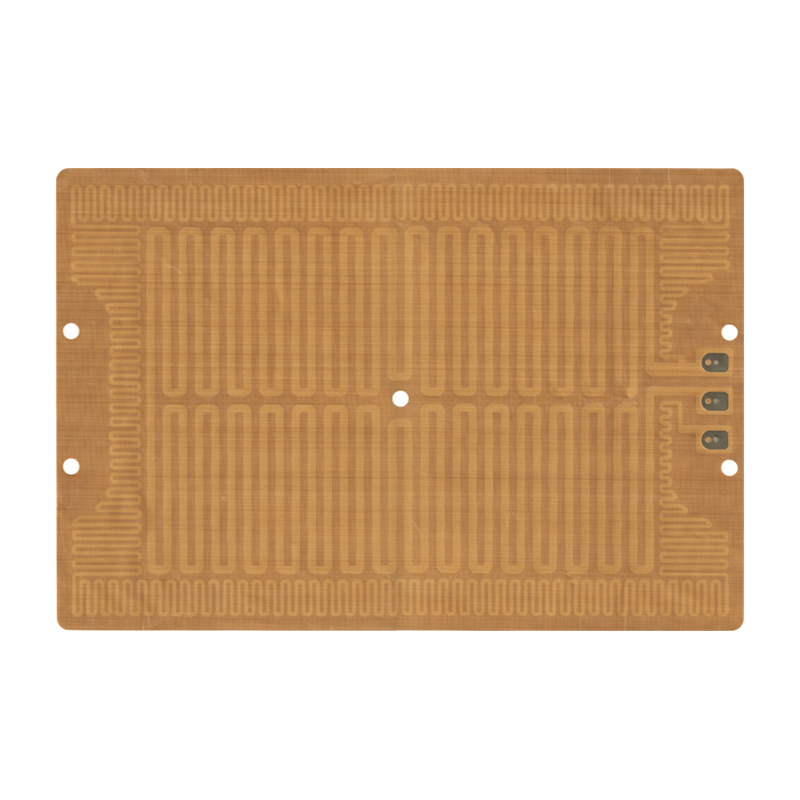

| Material | Teflon cloth metal etching | Power | customizable |

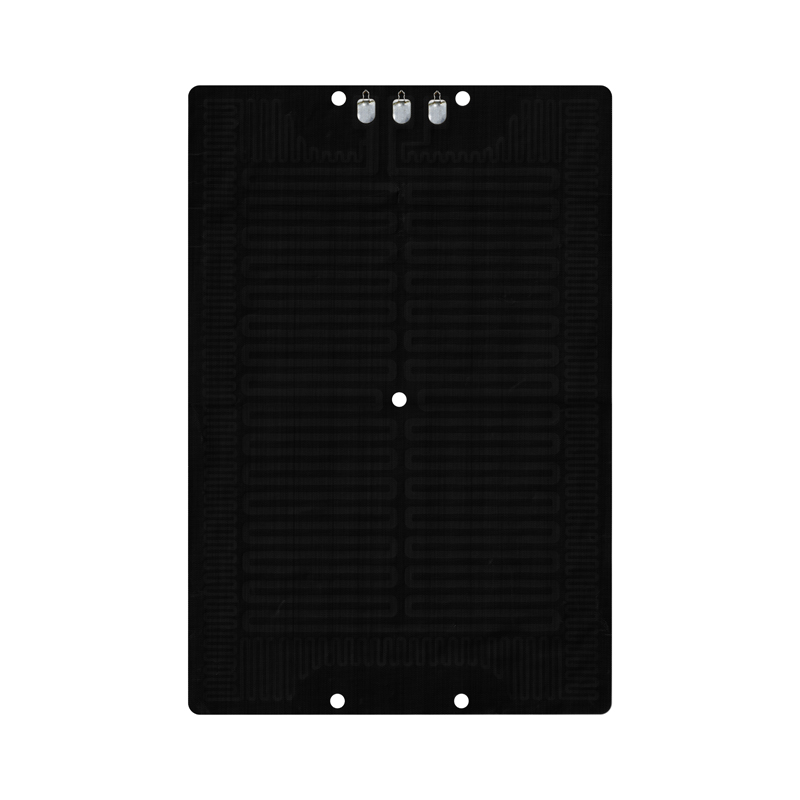

| Performance | fast heating intelligent constant temperature | Color | black, ochre yellow |

| Adjustable temperature | can be customized | Main purpose | heating constant temperature |

| Input voltage | 110V/220V | Size | can be customized multiple specifications |

What is a PTFE Teflon Heater?

PTFE Teflon Heater is a heating device utilizing PTFE (Polytetrafluoroethylene) material with high temperature resistance, corrosion resistance and low coefficient of friction, suitable for use in high temperature and corrosive environments.

What are the main application areas for PTFE Teflon Heaters?

The main areas of application include the chemical and pharmaceutical industries, the semiconductor industry, food processing and plastics processing.

What is the temperature range of PTFE heaters?

PTFE heaters are typically resistant to temperatures ranging from -200°C to 260°C.

What are the main benefits of PTFE Teflon Heater?

Key benefits include high temperature resistance, corrosion resistance, low coefficient of friction, high efficiency and long life.

How do PTFE heaters ensure efficient heating performance?

Through their uniform heating performance, PTFE heaters are able to reduce energy waste and improve overall thermal efficiency.

How do I install a PTFE Teflon Heater?

PTFE Teflon Heater can be mounted in the equipment by bolts, clamps or other fixings as required by the equipment.

Do PTFE heaters require any special maintenance?

Yes, PTFE heaters need to be inspected regularly for working condition to ensure that there is no damage such as cracking, peeling, etc. and avoid cleaning with strong acid and alkali solutions to prevent damage to the surface.

What is the corrosion resistance of PTFE heaters?

PTFE is extremely resistant to most chemicals and is suitable for use in chemical processing and corrosive environments.

What are the advantages of the low coefficient of friction of PTFE Teflon Heaters?

The low coefficient of friction reduces friction loss and is suitable for use in heating equipment that requires sliding, improving overall equipment performance.

What are the characteristics of PTFE Teflon Heater in food processing?

In food processing, PTFE heaters are able to effectively heat food products due to their high temperature resistance and safety, ensuring hygiene and quality in the production process.

Previous: Spiral heating element

Contact

No. 1, 1st Road, Mawu Industrial Zone, Qiaoli, Changping Town, Dongguan City, Guangdong Province

Email:

Phone:

+86 136-2001-9955

+86-0769-83488762-8016