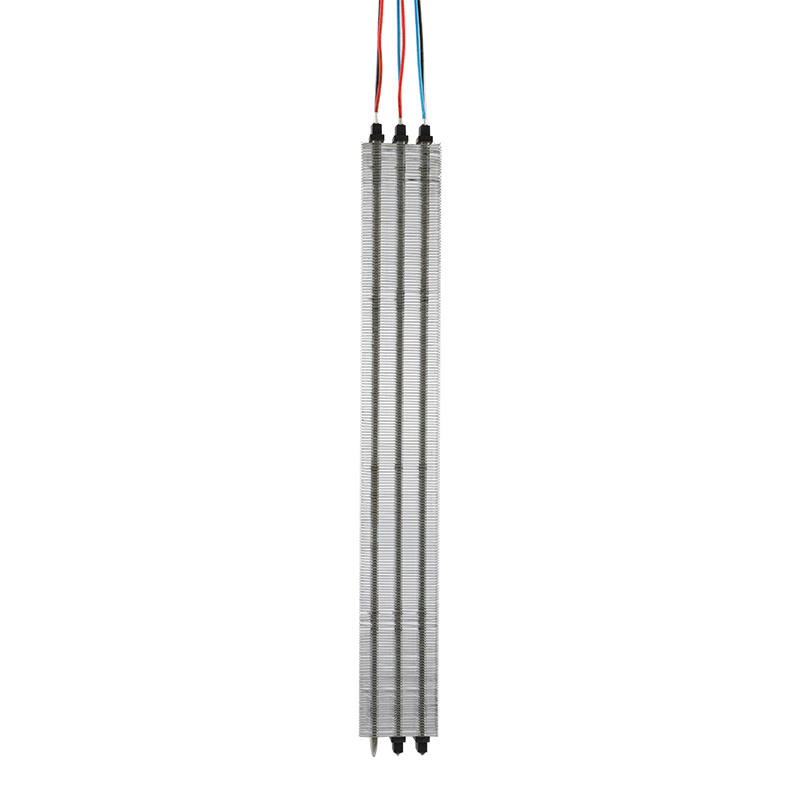

PTC Heating Element (PTC Heating Element) is a heating element based on Positive Temperature Coefficient (PTC) ceramic material. This material has a unique temperature sensitivity and self-control characteristics, so that the PTC heating element can automatically adjust the heating power in different ambient temperatures, so as to maintain a constant operating temperature.

PTC Heating Elements are heating devices based on Positive Temperature Coefficient (PTC) ceramic materials. These materials exhibit unique temperature sensitivity and self-regulating temperature characteristics, allowing PTC Heating Elements to automatically adjust their heating power in response to changes in ambient temperature, thereby maintaining a constant operating temperature.

The working principle of PTC Heating Elements is rooted in the temperature sensitivity and PTC characteristics of the material. At normal temperatures, the resistivity of PTC material is relatively low, allowing current to flow smoothly. However, as the temperature rises, the polycrystalline particles in the material begin to expand, causing the resistivity to increase rapidly. This change in resistivity limits the current flow, thereby reducing the heating power and achieving self-regulating temperature control.

Self-Regulating Temperature Control:

PTC Heating Elements have unique self-limiting temperature capabilities, enabling them to automatically adjust heating power in response to changes in ambient temperature, maintaining constant operation.

No additional temperature control systems are required, simplifying circuit design and reducing costs.

High Efficiency & Energy Saving:

PTC Heating Elements have high heat exchange efficiency, quickly converting electrical energy into thermal energy.

Once the set temperature is reached, due to the increase in resistivity, the heating power automatically decreases, achieving energy-saving effects.

Safety & Stability:

PTC Elements operate without open flames, reducing the risk of combustion and enhancing safety.

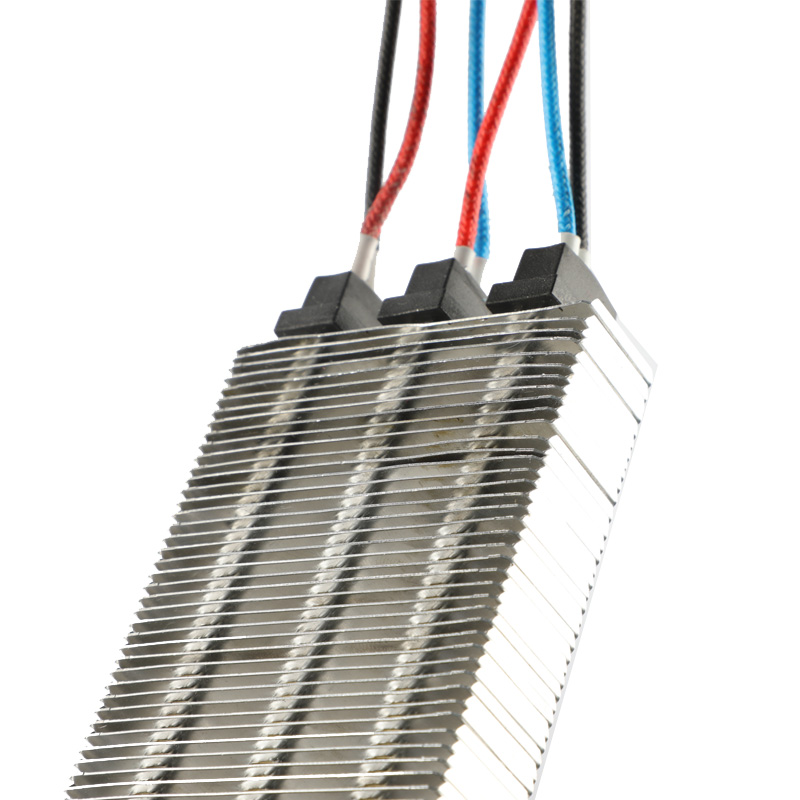

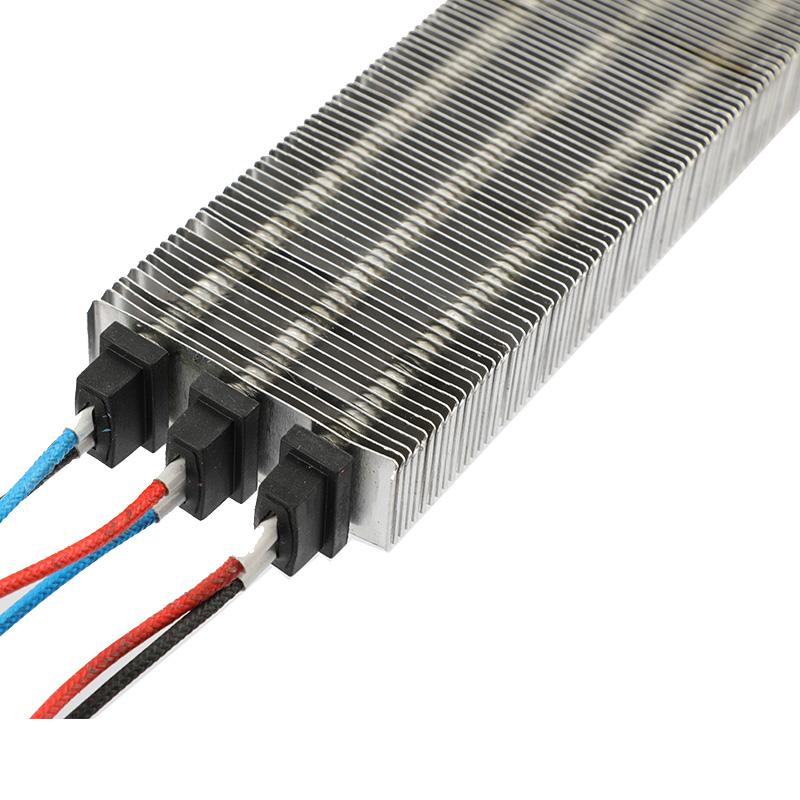

Double insulation protection prevents electrical shock hazards.

Even after prolonged operation, PTC Heating Elements do not overheat or become damaged.

Versatility & Flexibility:

PTC Heating Elements can be customized in various shapes, sizes, and powers to meet the needs of different applications.

They can be combined with various materials such as metals and plastics, increasing product diversity and flexibility.

Long Lifespan:

PTC Heating Elements have a long lifespan, often exceeding tens of thousands of hours.

Even in harsh environments, they maintain stable performance.

Due to their unique characteristics and advantages, PTC Heating Elements are widely used in various fields:

Household Appliances:

Such as electric water heaters, air purifiers, heaters, foot bathers, and electric heaters. PTC Heating Elements provide efficient and safe heating functions in these appliances.

They automatically adjust heating power to maintain a constant operating temperature, enhancing comfort and energy efficiency.

Automotive Industry:

Used in seat heating systems, glass defrosting systems, and engine preheating systems for electric vehicles.

PTC Heating Elements quickly respond and adjust heating power in these systems, ensuring vehicle comfort and performance stability under different ambient temperatures.

Medical Equipment:

Heating components for medical devices such as blood analyzers and infusion pumps.

PTC Heating Elements provide a constant operating temperature, ensuring accuracy and reliability of medical equipment.

Industrial Applications:

Heating systems for industrial equipment such as heating devices and greenhouses.

PTC Heating Elements automatically adjust heating power to meet heating needs in different applications.

The specific specifications and parameters of PTC Heating Elements may vary depending on the manufacturer and product model, but typically include the following:

Operating Voltage: Typically AC100250V or DC1236V, customizable based on actual needs.

Power: Varying from a few watts to several kilowatts depending on the application and heating requirements. Higher power results in faster heating but also higher energy consumption.

Surface Temperature: Typically below 400°C, adjustable based on actual needs. Higher surface temperature enhances heating effects but may also increase energy consumption and safety risks.

Curie Point: The maximum operating temperature of PTC Heaters, a key parameter for their self-regulating temperature characteristics. Higher Curie point improves temperature resistance but may also increase energy consumption and cost.

Size & Shape: PTC Heaters can be customized in various shapes, sizes, and structures to meet the needs of different applications.

Usage Precautions:

Ensure the operating voltage and power are within the rated range of the PTC Heating Elements to avoid overheating or damage.

Install PTC Heating Elements in a well-ventilated environment free of moisture and corrosive gases to ensure proper operation and lifespan.

When connecting power, ensure the power cord specifications and length meet requirements and use appropriate terminals for connection.

Maintenance Precautions:

Regularly inspect and maintain PTC Heaters, promptly cleaning dust and dirt from the surface to maintain good heat dissipation performance.

If PTC Heaters show signs of damage or cracks on the surface, replace them immediately to avoid potential safety hazards.

Store PTC Heaters in a dry, well-ventilated environment when not in use for long periods to prevent moisture and corrosion.

What is PTC heating element?

PTC heating element is a heating element made of PTC (Positive Temperature Coefficient) thermistor. It utilizes the constant temperature heating characteristics of PTC thermistor, and warms up self-heating after being charged, so that the resistance value enters into the leaping area, thus keeping the surface temperature constant.

What is the working principle of PTC heating element?

The working principle of PTC heating element is based on the constant temperature heating characteristic of PTC thermistor. When a PTC thermistor is energized, it warms up self-heating, resulting in an increase in resistance. This change in resistance value causes the current to decrease, thus limiting the heating power. When the heating power and heat dissipation power reaches a balance, the temperature will no longer rise, thus realizing the constant temperature heating.

What are the advantages of PTC heating elements?

PTC heating elements have a variety of advantages, including constant temperature heating, no open flame, high thermal conversion rate, minimal influence by supply voltage, and long natural life. In addition, it is characterized by fast heating, energy saving and environmental protection.

What are the disadvantages of PTC heating element?

The disadvantages of PTC heating element mainly include poor seismic performance and the inability to be cut and used at will. In addition, because it is limited by the Curie temperature, can not be used for heating above 350 ° C, so the application in the actual production and life can only be limited to the field of low-temperature heating.

What are the common application areas of PTC heating elements?

PTC heating elements are widely used in a variety of fields, including home life equipment such as heaters and water heaters, industrial processes such as plastic molding and metal heat treatment, aerospace heating and heat preservation, and medical equipment heating in the medical field.

How to choose the right PTC heating element?

Choosing the right PTC heating element requires consideration of a number of factors, including heating power, operating temperature, shape and structure, heat dissipation conditions, etc. In addition, the safety, energy efficiency, adaptability and durability of the element also need to be considered.

What is the service life of PTC heating elements?

The service life of PTC heating elements depends on a number of factors, including the operating environment, frequency of use, and maintenance. Under normal use and maintenance, high quality PTC heating elements usually have a long service life.

Does PTC heating element produce harmful substances during the heating process?

PTC heating elements do not produce harmful substances during the heating process and meet the requirements of environmental protection. It is heated without an open flame, avoiding the smoke and harmful gas emissions that may be produced by traditional heating elements.

How to maintain the PTC heating element?

When maintaining the PTC heating element, you need to pay attention to the following points: avoid impact or vibration of the element; keep the surface of the element clean to avoid the accumulation of dust and dirt; regularly check whether the connecting wires of the element and the thermostat are working properly; and avoid the element to work under high temperature or humid environment for a long time.

What is the future development trend of PTC heating element?

With the progress of science and technology and environmental awareness, the future development trend of PTC heating elements will pay more attention to energy efficiency, environmental protection and safety, as well as intelligent control and other aspects. At the same time, with the application of new materials and new technologies, the performance of PTC heating elements will be further improved and optimized.

Previous: Flexible Silicone Heater

Next: Rubber Heat Mat

Contact

No. 1, 1st Road, Mawu Industrial Zone, Qiaoli, Changping Town, Dongguan City, Guangdong Province

Email:

Phone:

+86 136-2001-9955

+86-0769-83488762-8016