PTC heaters offer a robust, energy-efficient, and safe heating solution for a wide range of industries and applications. Their ability to self-regulate temperature and prevent overheating makes them superior to traditional resistive heaters, and their versatility allows them to be tailored to specific needs. Whether in household appliances, automotive systems, or industrial heating processes, PTC heaters deliver reliable performance, safety, and long-term cost savings.

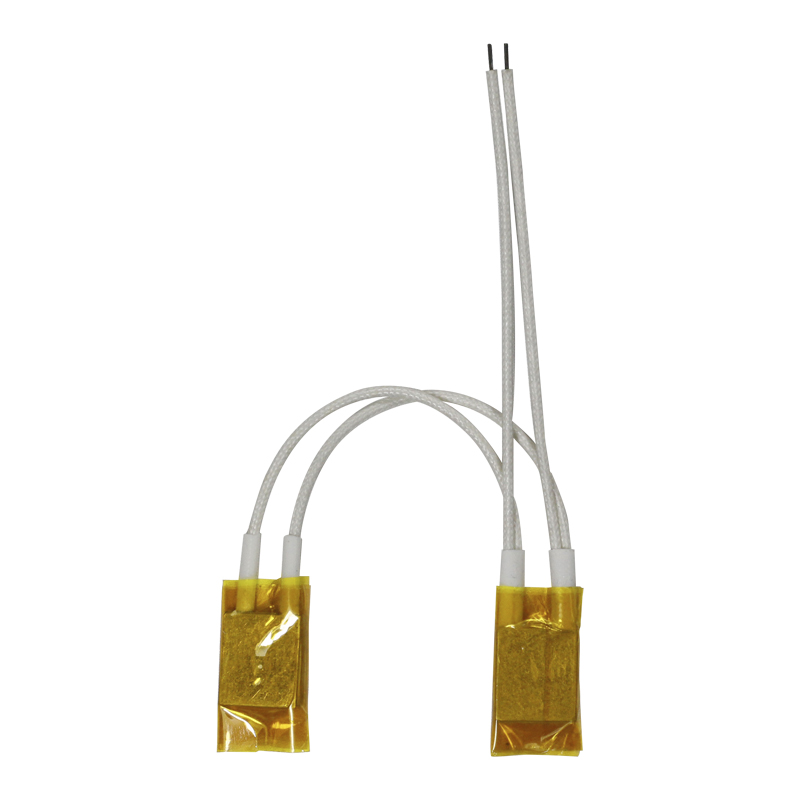

A Positive Temperature Coefficient (PTC) Heater is a type of heating element that exhibits self-regulating behavior, making it highly efficient and safe for a wide range of applications. These heaters use PTC materials, typically ceramics, that increase in resistance as they heat up, thereby limiting the amount of current that flows through them. This unique feature allows the heater to automatically regulate its temperature without the need for external control systems, reducing the risk of overheating and improving overall energy efficiency.

Key Features:

Self-Regulating:

Unlike traditional heating elements that require thermostats or other control systems to regulate temperature, PTC heaters naturally adjust their resistance as they warm up. This self-regulating feature ensures that they will not exceed a specific temperature, offering a safe and reliable heating solution.

Material Composition:

The heating element is typically made from PTC ceramics, such as barium titanate, which have a positive temperature coefficient. These materials are designed to increase resistance as temperature rises, allowing the heater to limit its current draw as it reaches its optimal operating temperature.

Fast Heating:

PTC heaters heat up quickly, providing immediate warmth or heat. They reach a specific set point and maintain that temperature, ensuring fast response times and consistent heat output.

Safe Operation:

The PTC heater is inherently safer than conventional heaters because it avoids excessive temperature increases. Once the target temperature is reached, the resistance becomes high enough that additional current flow and heat generation are minimized.

Energy Efficient:

As the heater automatically reduces current draw when it reaches the desired temperature, it uses only the energy necessary to maintain a constant heat level. This makes PTC heaters more energy-efficient compared to traditional resistive heating elements.

Operating Voltage: Commonly available in a range of 12V, 24V, 110V, 220V, and 240V, suitable for both low-voltage and high-voltage applications.

Operating Temperature Range: Generally operates between 60°C to 250°C (140°F to 482°F), depending on the application and model.

Power Output: PTC heaters typically range from 10W to 2000W, but the exact output depends on the surface area, voltage, and application.

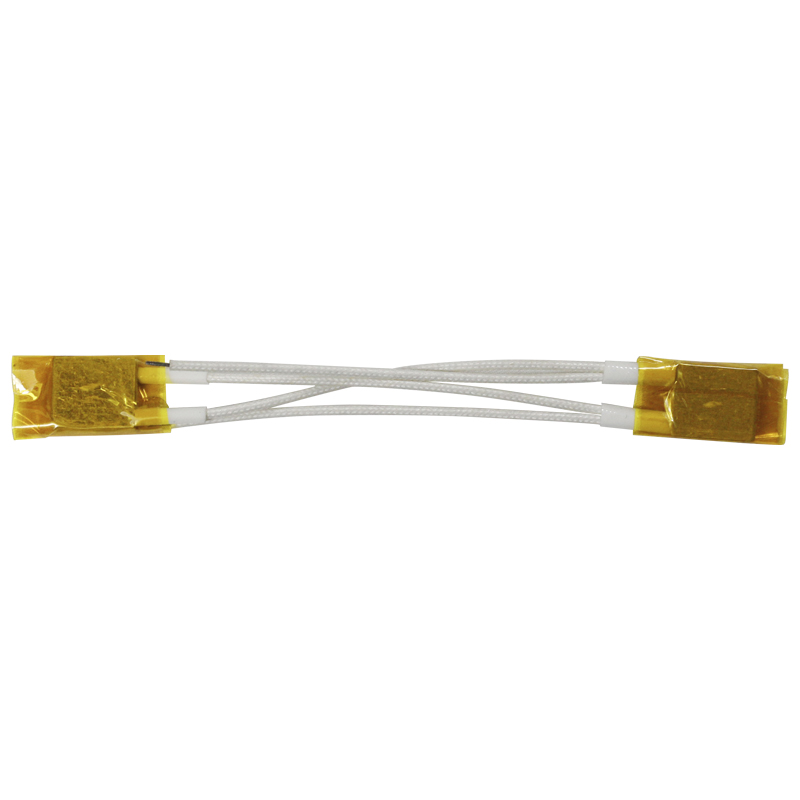

Dimensions: Available in various sizes and shapes, including flat plates, honeycomb structures, tubular forms, and flexible PTC heaters, depending on the application and installation needs.

Lifespan: Long operating life with a typical lifespan of up to 10,000 hours or more, depending on usage conditions.

Household Appliances:

PTC heaters are commonly used in space heaters, hair dryers, water heaters, electric blankets, and air conditioners due to their efficient heat generation and safety features.

Automotive Industry:

These heaters are widely used in defrosting and de-icing systems, seat warmers, and heating, ventilation, and air conditioning (HVAC) systems in electric and hybrid vehicles.

Industrial Heating:

PTC heaters are employed in various industrial settings such as warehouse heating, machinery heating, and temperature control systems, where a safe, consistent heat output is required.

Medical Devices:

They are used in medical equipment where precise temperature control is necessary, such as incubators, therapeutic devices, and other heating systems in healthcare applications.

Battery Warmers:

PTC heaters are used in cold environments to maintain the optimal operating temperature of lithium-ion batteries, ensuring efficient performance in electric vehicles and energy storage systems.

Underfloor Heating:

PTC heating elements are commonly embedded in underfloor heating systems, providing energy-efficient, even heat distribution throughout a room.

Commercial and Consumer Electronics:

PTC heaters are found in devices such as printers, copiers, and other office equipment that require consistent internal temperatures for proper operation.

Automatic Temperature Control:

The self-regulating nature of PTC heaters eliminates the need for complex control systems, ensuring they maintain a safe and consistent temperature without risk of overheating.

Energy Efficiency:

By reducing power consumption once the desired temperature is reached, PTC heaters minimize energy waste, making them a cost-effective heating solution.

Long Lifespan:

PTC heaters have fewer mechanical parts and are more durable than traditional heating elements, leading to a longer operating life and reduced maintenance costs.

Compact Design:

The flexibility of PTC material allows for various form factors, making these heaters suitable for space-constrained applications.

Safe and Reliable:

The inability to overheat makes PTC heaters an ideal choice for applications where safety is paramount, such as in medical and household appliances.

What is a Positive Temperature Coefficient (PTC) Heater?

A PTC heater is a type of heating element that uses materials with a positive temperature coefficient, meaning their resistance increases as temperature rises. This causes the heater to self-regulate and avoid overheating.

How does a PTC heater work?

A PTC heater operates by passing electrical current through a resistive material (usually a ceramic). As the material heats up, its resistance increases, which reduces the current flow and limits further heating, creating a self-regulating effect.

What materials are used in PTC heaters?

PTC heaters typically use ceramic materials like barium titanate, which have a positive temperature coefficient. The ceramic element is often coated with metals such as aluminum to improve heat transfer.

What are the advantages of using PTC heaters?

PTC heaters are energy-efficient, self-regulating, safe, and have a long lifespan. They also heat up quickly and do not require additional temperature control systems, making them more cost-effective in the long run.

What applications are PTC heaters used for?

PTC heaters are widely used in household appliances (e.g., hair dryers, space heaters), automotive applications (e.g., defrosters, seat heaters), industrial equipment, underfloor heating, medical devices, and more.

Why are PTC heaters considered safer than traditional resistive heaters?

PTC heaters are safer because they self-regulate. Once they reach a specific temperature, their resistance increases, which limits the current and prevents the heater from overheating, reducing the risk of fire or damage.

Do PTC heaters require additional temperature controls or thermostats?

No, PTC heaters do not need external thermostats or temperature controls because they automatically adjust their resistance as they heat up, providing built-in temperature regulation.

How energy-efficient are PTC heaters compared to conventional heaters?

PTC heaters are more energy-efficient because they reduce their power consumption once they reach a stable temperature. Unlike conventional heaters, they do not continually draw full power, which minimizes energy waste.

Can PTC heaters be used in cold environments?

Yes, PTC heaters are commonly used in cold environments, such as in battery warmers for electric vehicles, defrosting systems, and other applications where maintaining a certain temperature is crucial.

How long do PTC heaters typically last?

PTC heaters generally have a long operational lifespan due to their durable ceramic materials and the fact that they don’t overheat. Their lifespan can exceed 10,000 hours depending on usage conditions and maintenance.

Previous: Silicone Rubber Heater

Next: Heating Wire

Contact

No. 1, 1st Road, Mawu Industrial Zone, Qiaoli, Changping Town, Dongguan City, Guangdong Province

Email:

Phone:

+86 136-2001-9955

+86-0769-83488762-8016