Heating elements are crucial components in modern heating devices, characterized by efficiency, durability, and flexibility. Whether used in homes, industries, or medical applications, selecting the appropriate heating element effectively meets various thermal energy needs and enhances overall equipment performance and user experience. Proper installation and maintenance ensure reliable operation over time.

Heating Elements are devices designed to convert electrical energy into heat efficiently. They are core components in various heating devices, including heaters, electric water heaters, ovens, and temperature controllers. The primary function of a heating element is to provide reliable and consistent heat output, suitable for use in homes, industries, and medical applications.

The fundamental working principle of a heating element is based on the resistive heating effect, where electric current flowing through a conductor generates heat. When electric current passes through the heating element, the resistive material converts electrical energy into thermal energy, which is then released into the surrounding environment through radiation, convection, or conduction.

Current Flow: When the heating element is connected to a power source, electric current begins to flow.

Heat Generation: As current flows through the resistive material, heat is generated due to resistance.

Heat Dissipation: The produced heat radiates through the surface of the element, directly heating adjacent air, liquids, or solids.

This process is typically rapid, allowing the heating element to reach the desired operational temperature within seconds, effectively meeting user heating requirements.

High Efficiency: Heating elements are designed for rapid heating, capable of reaching the desired temperature quickly, making them ideal for applications that require instant heat.

Durability: Constructed to withstand high temperatures and extreme conditions, ensuring long-term stability and reliability.

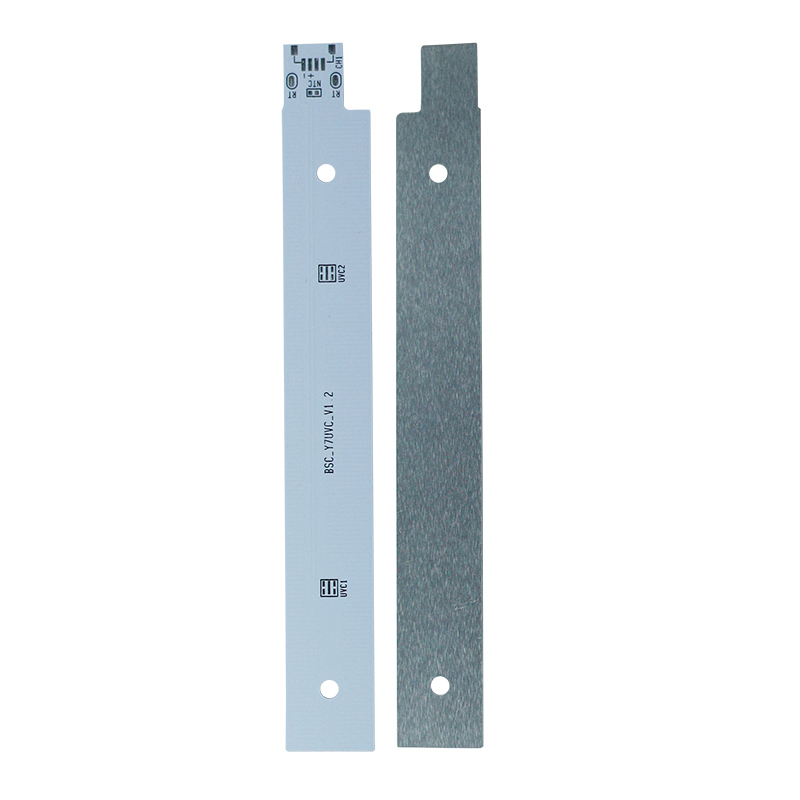

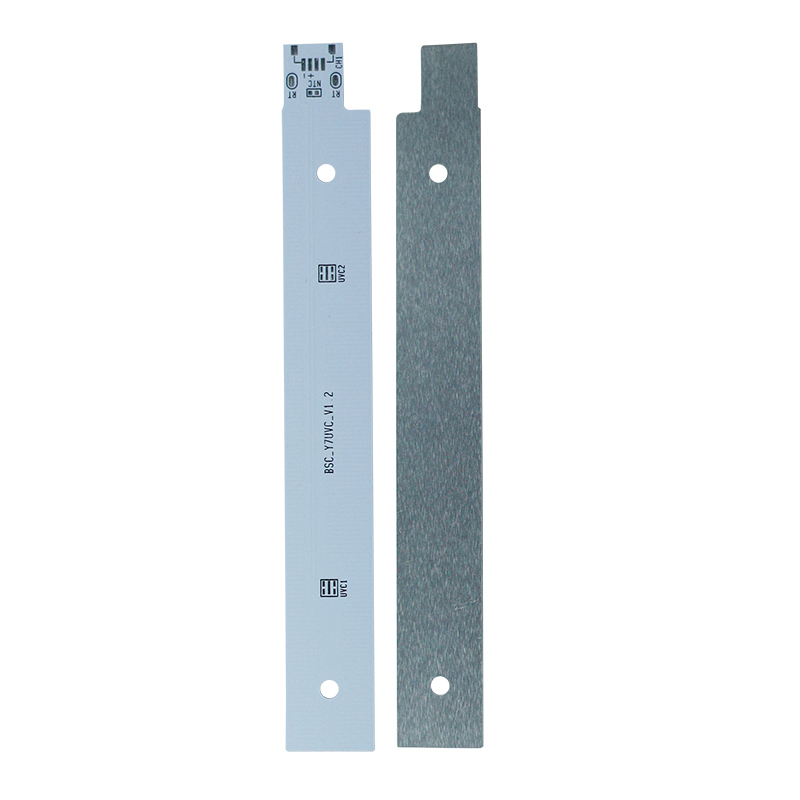

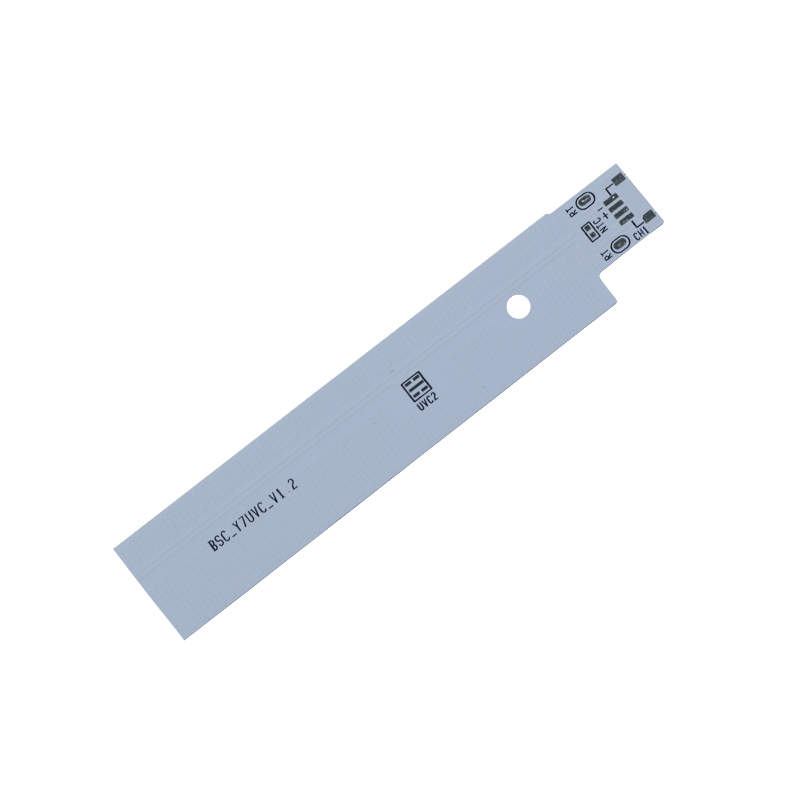

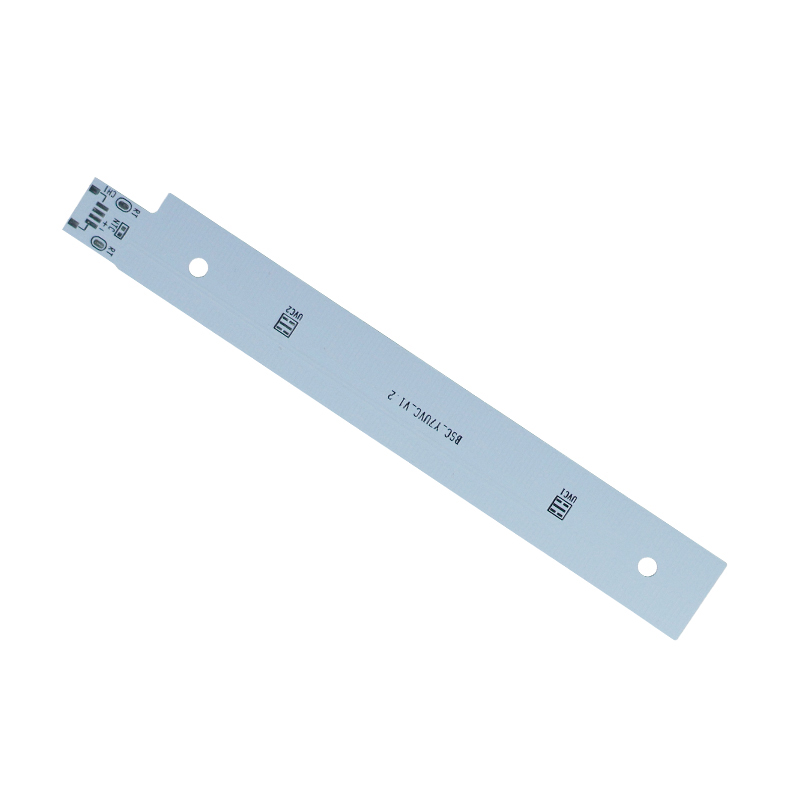

Flexibility: Many heating elements can be cut or shaped to meet specific heating needs, accommodating irregular surfaces or configurations.

Safety: Integrated with various safety features, including overheat protection, short-circuit protection, and automatic shut-off functions to prevent accidents and enhance user safety.

Energy Efficiency: Many heating elements are optimized to minimize energy loss, ensuring efficient operation and reduced energy consumption.

Heating elements have a broad range of applications, including but not limited to:

Home Appliances:

Electric Water Heaters: Quickly heat water for domestic use.

Ovens: Provide even heating for baking and roasting.

Electric Blankets: Offer comfortable warmth for users.

Industrial Equipment:

Plastic Molding: Used in the manufacturing process to melt and mold plastics.

Food Processing: Heats equipment for cooking and processing food to ensure safety and quality.

Metal Heating: Used in metalworking for processes like welding and shaping.

Automotive Industry:

Battery Heating: Enhances battery performance, ensuring functionality in low-temperature environments.

Seat Heating: Provides warmth for passengers, improving comfort.

Medical Devices:

Therapeutic Equipment: Used for muscle pain relief and to promote circulation through heat.

Heating Pads: Provide heat therapy for recovery and comfort.

Installation:

Position Selection: Choose an appropriate installation location to ensure optimal heating performance.

Power Connection: Ensure a secure electrical connection to avoid loose connections or short circuits.

Securing the Element: Use suitable methods to firmly secure the heating element, preventing vibration or movement.

Maintenance:

Regular Inspections: Frequently check power lines and connections for wear or aging.

Cleaning: Keep the surface of the heating element clean to avoid dust and debris that can affect heat dissipation.

Performance Testing: Periodically test the heating element to ensure it operates correctly and reaches the specified temperature.

Troubleshooting:

Power Check: If the heating element fails to heat, first check whether power is being supplied correctly.

Connection Check: Inspect all connections for looseness or disconnection.

Thermostat Testing: Ensure the thermostat is set correctly and functioning properly

What is a heating element?

A heating element is a device that converts electrical energy into heat through resistive heating. It is commonly used in appliances like heaters, ovens, and electric water heaters.

How does a heating element work?

A heating element works by allowing electric current to flow through a resistive material. As the current passes through, it generates heat due to the resistance of the material, which then radiates into the surrounding environment.

What materials are commonly used in heating elements?

Common materials include nickel-chromium alloys, kanthal, and other high-resistance metals. These materials can withstand high temperatures and provide efficient heating.

What are the main applications of heating elements?

Heating elements are used in various applications, including:

Home appliances (e.g., electric ovens, water heaters)

Industrial processes (e.g., plastic molding, food processing)

Automotive heating (e.g., seat heaters, battery warmers)

Medical devices (e.g., heating pads, therapeutic equipment)

What safety features are included in heating elements?

Safety features may include overheat protection, short-circuit protection, and automatic shut-off functions to prevent overheating and ensure user safety.

How can I maintain a heating element?

To maintain a heating element, regularly inspect connections for wear, keep the surface clean to avoid debris buildup, and periodically test its performance to ensure it operates correctly.

What should I do if my heating element is not working?

If a heating element is not working, check the power supply, inspect all electrical connections, and ensure that the thermostat is functioning properly. If the issue persists, the heating element may need to be replaced.

Can heating elements be customized for specific applications?

Yes, heating elements can be customized in terms of size, power rating, and design to meet specific application requirements, including temperature ranges and shapes.

How do I choose the right heating element for my application?

To choose the right heating element, consider factors such as the required power output, operating temperature, physical dimensions, and the specific heating application. Consulting with a manufacturer or supplier can also help in selecting the most suitable element.

Previous: Seedling Mat

Next: Heating Film

Contact

No. 1, 1st Road, Mawu Industrial Zone, Qiaoli, Changping Town, Dongguan City, Guangdong Province

Email:

Phone:

+86 136-2001-9955

+86-0769-83488762-8016