PI Heating Film is efficient, durable and environmentally friendly, and is especially suited to applications that require stable operation at high temperatures for long periods of time.PI Heating Film is not only suitable for domestic and commercial underfloor heating, but can also be used in a wide range of industrial and specific applications to meet the diverse needs of heating equipment for a wide range of applications.

Heating Film generates heat through electric current and uses far infrared heating technology to emit uniform far infrared rays.The conductive layer inside the PI Heating Film, which is usually made up of carbon nano-ink or metal alloy, efficiently converts electrical energy into heat and spreads the heat in the form of far infrared rays. This type of heating ensures the temperature of the whole membrane is uniform and avoids the localized high temperature problem of traditional heating equipment.

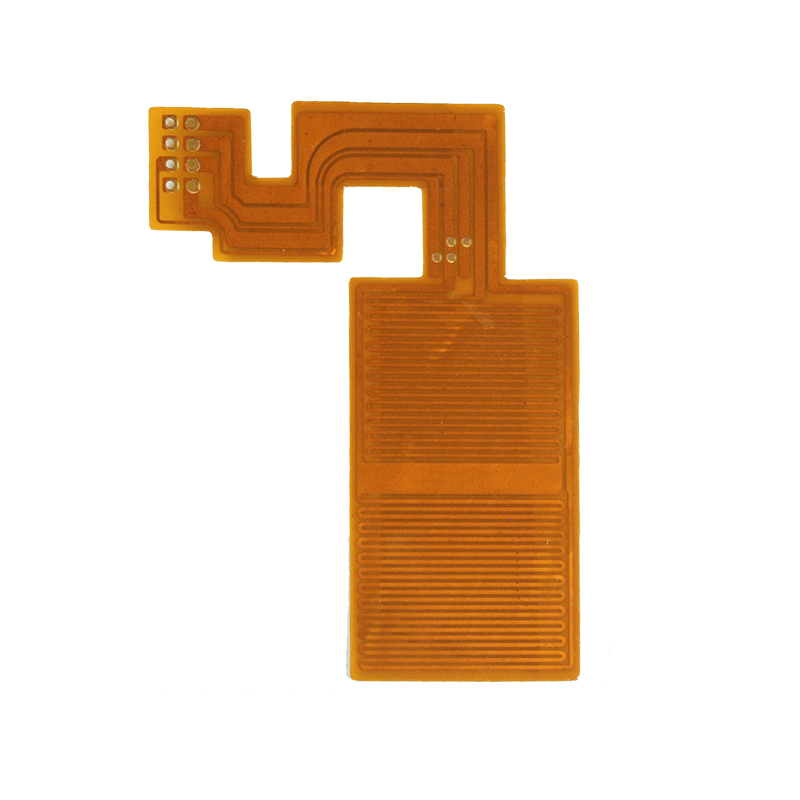

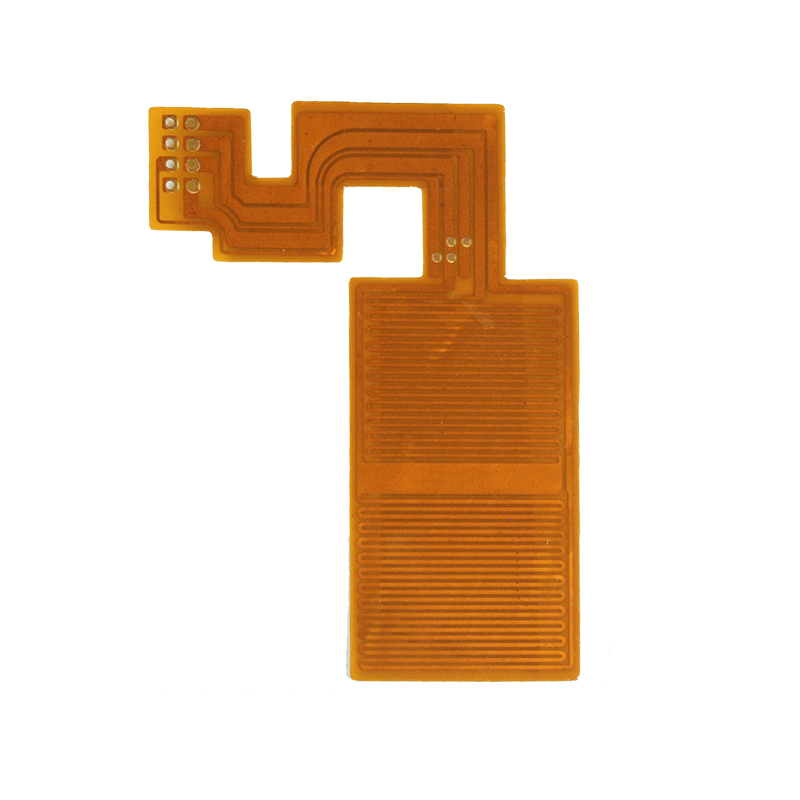

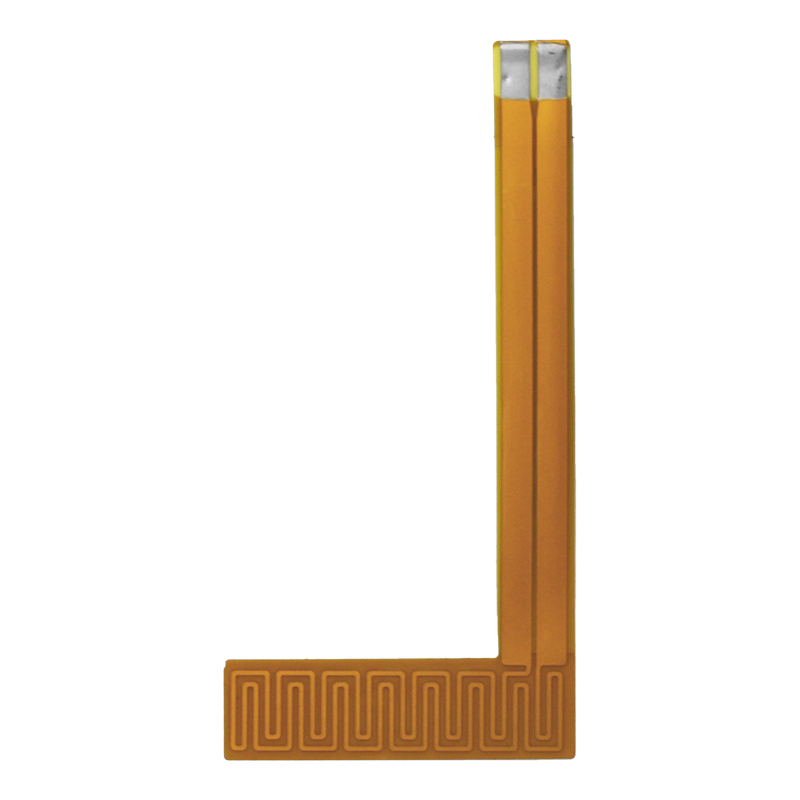

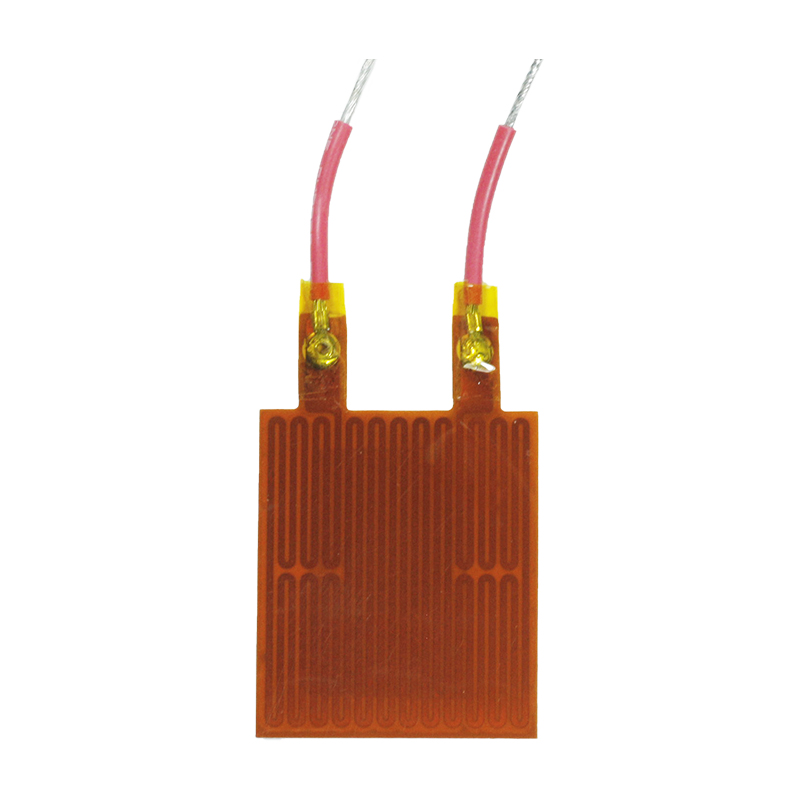

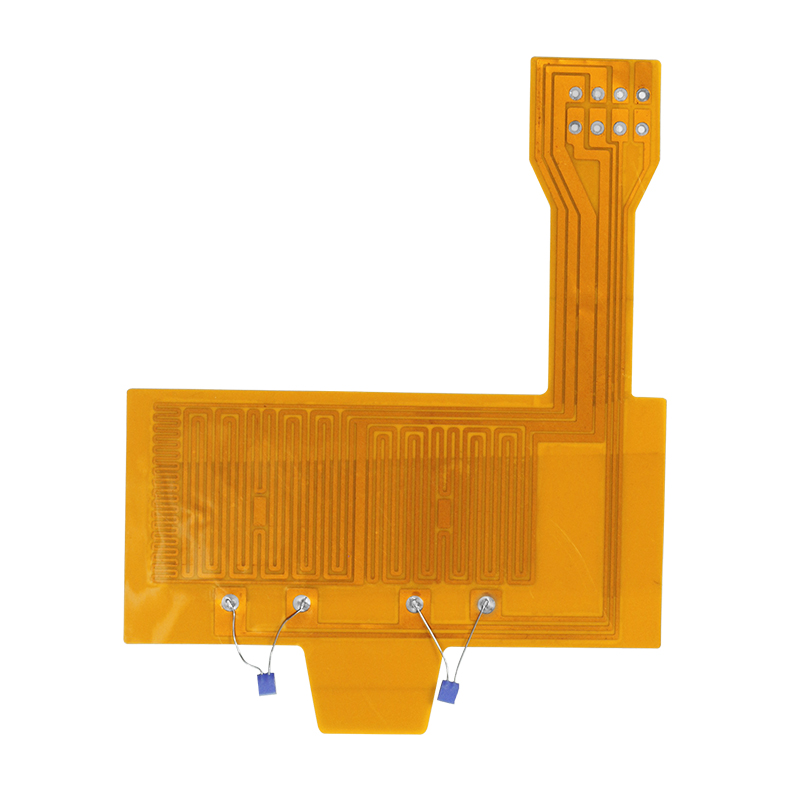

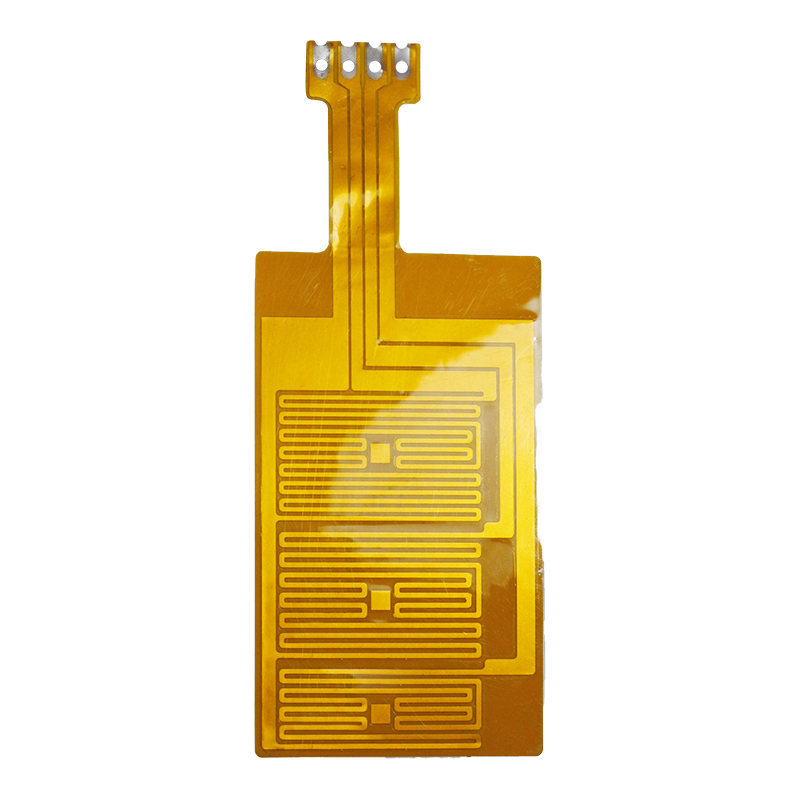

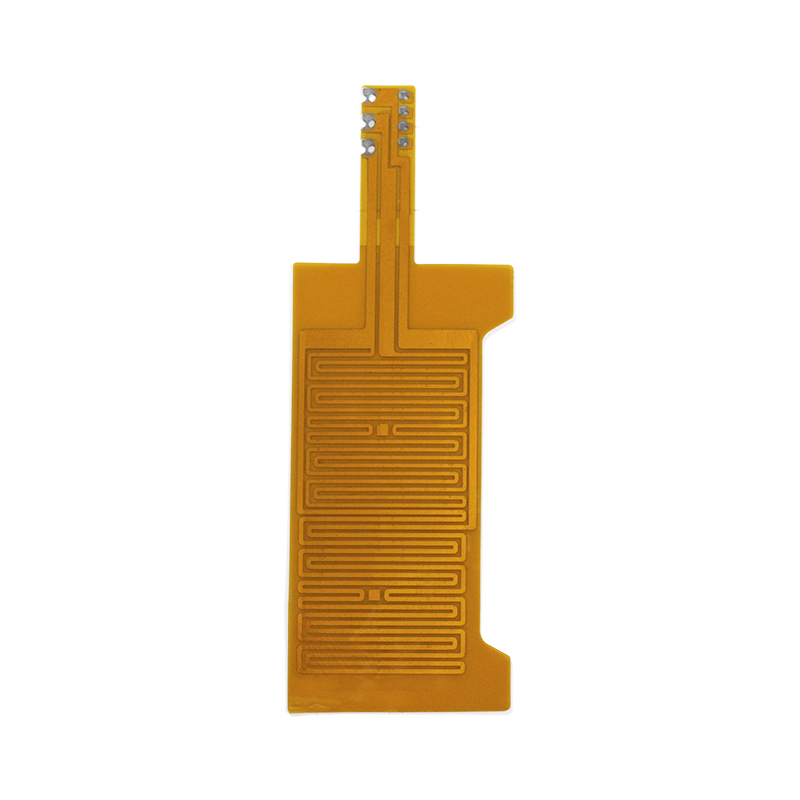

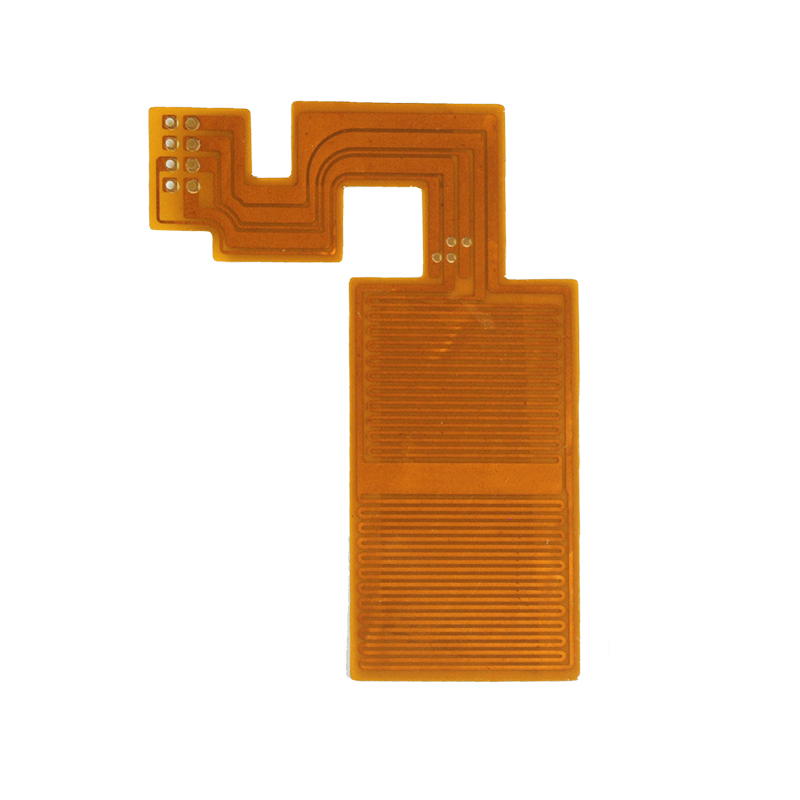

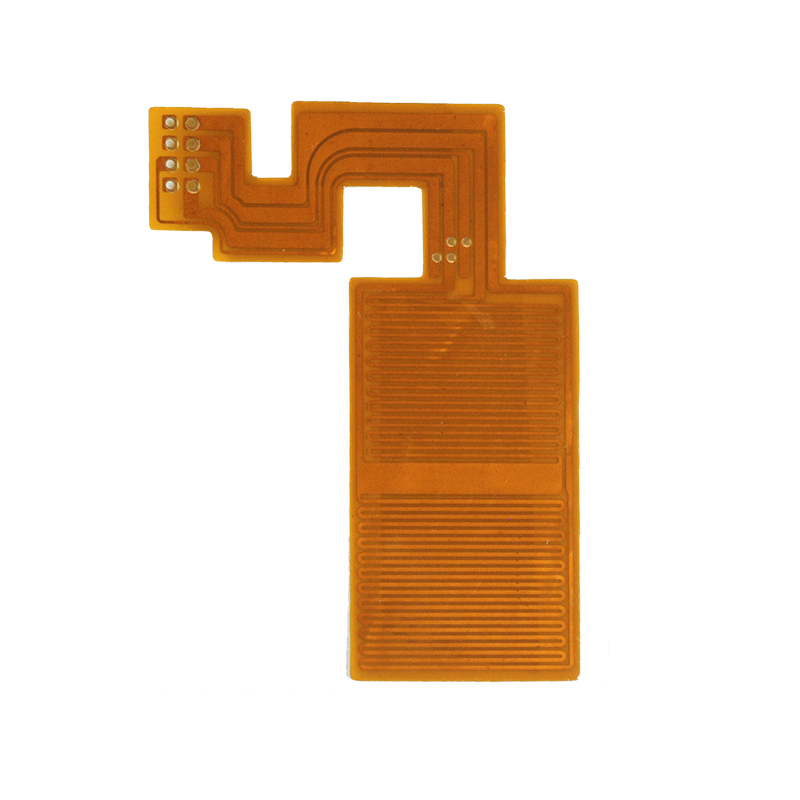

Material and Structure

1. Core Material: Heating Film adopts Polyimide (PI) as the base material, which has excellent high temperature resistance and excellent chemical stability, and is able to operate stably under extreme temperatures. This makes the Heating Film more durable and suitable for long term use.

2. Heating Layer Material: Nano carbon ink or metal coating is usually used as the heating material. These conductive materials have good thermal conductivity, so that the heat can be evenly distributed on the whole film surface.

3. Multi-layer structure: PI Heating Film usually adopts multi-layer composite design, with insulation protection layer on both sides of the heating layer to ensure its safety and reliability in various environments, PI material can not only withstand high temperature, but also has good electrical insulation to ensure the safety of the heating film.

Product characteristics and advantages of PI material heating film

1. High Temperature Resistance: PI material has high heat resistance and can work stably in the temperature range of -200°C to 300°C, which makes it especially suitable for applications requiring long time or high temperature working.

2. High efficiency and energy saving: The heating film adopts PI material with high energy conversion efficiency, which can realize high efficiency heating under low power, save energy and reduce power consumption.

3. Healthy far infrared rays: the far infrared rays emitted by PI Heating Film have physical therapy effect on human body, which can penetrate into the subcutaneous tissue layer, promote blood circulation and bring comfortable heating experience.

4. Thin and light design: The thickness of PI Heating Film is usually between 0.1mm - 0.2mm, which is very thin and light, suitable for hidden installation, does not take up space and can be integrated into the interior design.

5. Safety: PI material has a high degree of heat resistance and good insulation, can prevent leakage and overheating, greatly enhancing the safety performance of the heating film, to ensure that the user can rest assured that the use.

Application Scenarios

After adopting PI material, Heating Film is widely used in domestic, commercial and industrial environments, especially suitable for applications with high temperature and high stability requirements, specifically including:

1. Underfloor heating system: as the core element of the underfloor heating system, it can be installed under tiles, wooden floors and laminated floors to provide even underfloor heating effect.

2. Industrial heating equipment: Suitable for heating applications in industrial equipment that require high temperatures and long hours of continuous work, such as heating boxes, experimental instruments, and industrial drying equipment.

3. Battery heating: The thin and high temperature resistant characteristics of PI heating film make it suitable for application in battery heating, especially in cold environments, to prevent battery failure or performance degradation.

4. Medical equipment: Due to the chemical stability and high temperature resistance of PI material, the heating film can also be used in medical equipment that requires constant temperature, such as blood heaters, physical therapy pads, etc.

Installation and Maintenance

1. Installation method:

Preparation for laying: Make sure the installation surface is flat and clean from debris.

Heating film laying: Cut the PI heating film to the required size and fix it to the surface such as floor, wall or ceiling using special tape.

Power supply access: select the power cable connection according to the specifications to ensure a firm connection to avoid the risk of short-circuit.

Temperature control system connection: It is recommended to combine with intelligent temperature control system to conveniently adjust the temperature and realize energy-saving effect.

2. Maintenance requirements:

PI Heating Membrane usually does not require frequent maintenance, only need to check the cable and thermostat regularly after installation. Keep the surface clean and avoid sharp objects scratching the surface of the heating membrane.

Technical Advantages of PI Heating Membrane

1. High-temperature stability: PI material has excellent high-temperature resistance, and can maintain stable performance in harsh environments, suitable for long-term continuous use.

2. Precise temperature control: the temperature of the heating film can be precisely adjusted by the intelligent control system to meet the temperature requirements of different scenarios.

3. Lightweight and flexible: PI heating film is thin and flexible, can fit irregular surfaces, suitable for a variety of installation needs, especially in the need for high-temperature heating and small size of the industrial scene.

4. Low energy consumption, environmental protection: heating film on the basis of PI material to further reduce energy consumption, and does not produce pollutants or harmful gases, in line with modern environmental requirements.

What is heating film?

Heating film is a thin heating device that generates heat through electric current, typically utilizing far-infrared heating technology to convert electrical energy into heat, providing uniform heating effects.

What are the main materials used in heating film?

The primary material for heating film is polyimide (PI), known for its excellent high-temperature resistance and chemical stability, making it suitable for long-term use. The heating layer usually consists of nano carbon ink or metal alloys.

How does heating film work?

Heating film operates by allowing electric current to flow through the heating layer, which generates heat and emits it as far-infrared radiation, providing a comfortable heating effect. The far-infrared radiation penetrates deep into objects, enhancing warmth.

What is the lifespan of heating film?

The lifespan of heating film typically exceeds 10 years, depending on the usage environment and maintenance practices.

What are the common applications of heating film?

Heating film is widely used in home underfloor heating systems, wall heating, industrial equipment heating, battery heating, and medical devices, especially in environments requiring high temperatures and stability.

How difficult is it to install heating film?

Installing heating film is relatively straightforward. It generally involves laying the film on a floor or wall and connecting it to the power supply and thermostat. Ensuring a smooth, dry surface is key to successful installation.

How safe is heating film?

Heating film has excellent electrical insulation properties and high-temperature resistance, often equipped with overheat protection devices to prevent electric leakage and overheating, ensuring safe use.

How should heating film be maintained?

Heating film typically requires minimal maintenance. Regularly check the power cords and thermostat functionality, and keep the surface clean to avoid scratches from sharp objects.

Can heating film be integrated with smart home systems?

Yes, heating film can be compatible with smart thermostat systems, allowing for precise temperature control and scheduled heating, enhancing convenience and energy efficiency.

What is the energy efficiency of heating film?

Heating film demonstrates high energy conversion efficiency, providing sustained warmth at lower power levels, making it more energy-efficient than traditional heating devices and reducing electricity consumption.

Previous: Heating Element

Next: Seedling Heat Mat

Contact

No. 1, 1st Road, Mawu Industrial Zone, Qiaoli, Changping Town, Dongguan City, Guangdong Province

Email:

Phone:

+86 136-2001-9955

+86-0769-83488762-8016