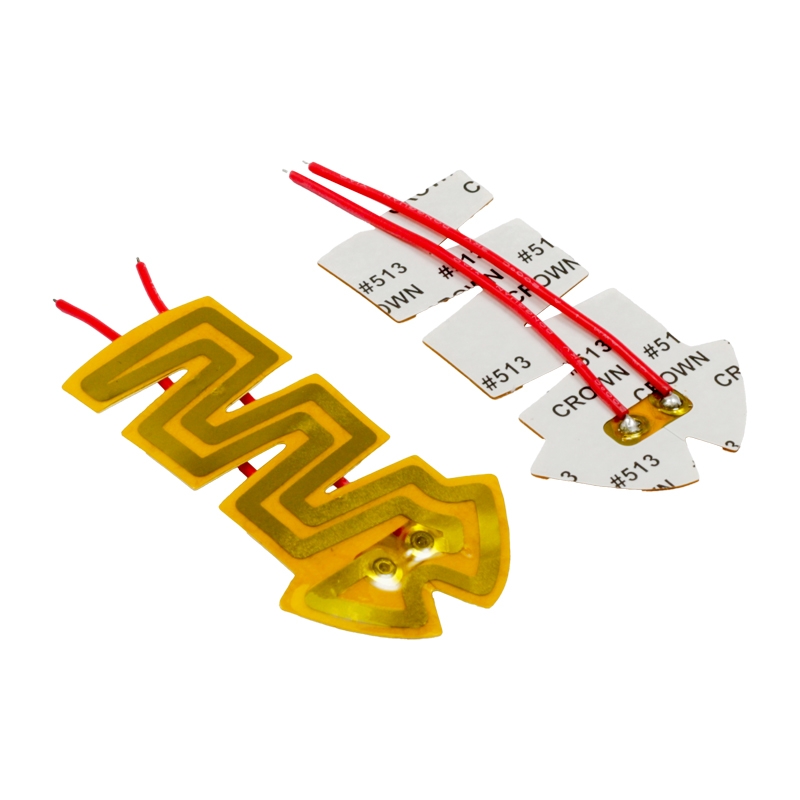

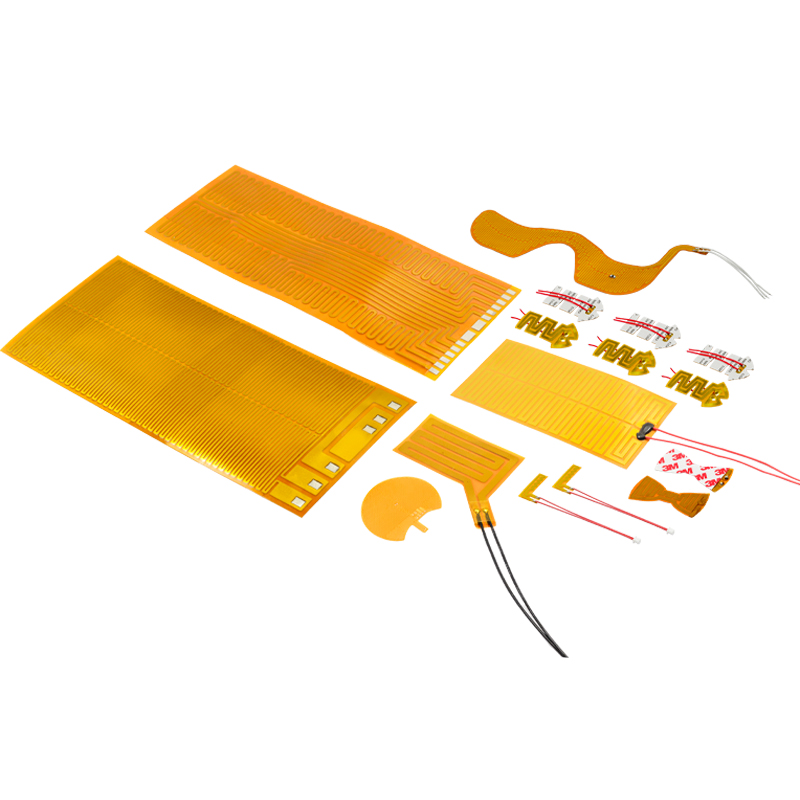

PI Heating Film is a high-performance heating film made of polyimide with excellent resistance to high temperatures, chemicals, and flexibility, and is widely used in electronic equipment, automotive, and industrial heating applications.

PI Heating Film is a composite material with PI heating film as the outer insulator and metal foil or wire as the inner conductive heat generator. This material is thermally bonded at high temperature and high pressure, and has excellent insulating strength, electric resistance, heat transfer efficiency and resistance stability.

Product Characteristics

1. Excellent insulating strength:PI heating film has high insulating strength, which makes it safe for use in various electrical equipment.

2. Excellent electrical strength:it can withstand higher voltages without breakdown, which increases its reliability in high-voltage environments.

3. Excellent heat transfer efficiency:PI heating film heaters are able to conduct heat quickly, which makes them very effective in heating applications.

4. Excellent resistance stability:Its resistance value can remain stable during long-term use, which helps to maintain equipment performance and heating efficiency.

5. High temperature tolerance:PI heating film electric heating film can be used for a long time in high temperature environments, the use temperature can reach 232 ℃.

6. Lightweight:PI heating film electric heating film is lightweight, which is very useful in applications where the weight of the equipment needs to be reduced.

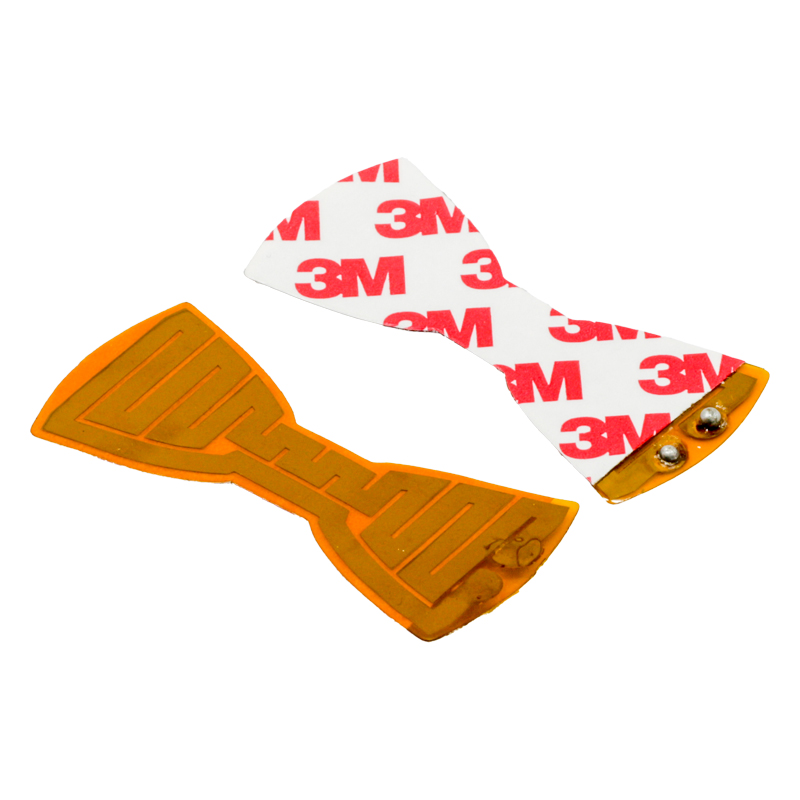

7. Thin:The film form makes it easy to install and use in space-constrained applications.

8. Wide range of applications:Due to the above characteristics, PI heating film is widely used in aerospace, military equipment, medical equipment, scientific instruments and automotive industry.

9. Precise temperature control:it can realize quite high temperature control precision in the heating field, which is suitable for the occasions that need precise temperature control.

10. Good compatibility:it can be compatible with a wide range of materials and equipment, easy to integrate into existing systems.

11. Chemical resistance:polyimide material itself has good chemical stability, able to resist the erosion of a variety of chemicals.

12. Mechanical properties:PI heating film has high mechanical strength and flexibility, able to withstand certain mechanical stress.

Working principle

The metal heat sink acts as the heat generator, and the polyimide (PI) film acts as the outer insulating material. When the electric current passes through the metal heat sink, according to Ohm's law, the electric energy will be converted into heat energy, and the metal sheet will be heated due to resistance. Since the metal has good thermal conductivity, it can quickly conduct the heat energy converted from electrical energy to the contact objects. At this time, the PI heating film not only as an insulating layer to prevent current leakage, but also play a role in insulating and protecting the metal heat sink, its temperature resistance and electrical insulation properties to ensure that the metal sheet at high temperatures are not oxidized or damaged. Eventually, the object to be heated comes into contact with the polyimide metal heat sink, and through the heat conduction properties of the film, the heat energy is transferred to the surface of the object in a short period of time, realizing the heating effect. This kind of heating film has high heating efficiency and fast heating speed, applicable to a variety of occasions requiring heating treatment .

The heat transfer efficiency and resistance stability of PI heating film heating foils are due to their material properties, including excellent dielectric strength, electrical resistance and temperature limitation (≤ 232 °C) for long-term use. These properties make polyimide metal heating film play an important role in applications such as scientific analyzers, medical instruments, deep-cooled environmental equipment, vacuum heating and baking fields, defrosting sheets for automotive mirrors, snow and frost removal heating elements for antennas or radars, and speed-regulating resistor sheets.

Application Fields

1. Aerospace field:PI heating film electric heating film has been successfully applied in high-end equipments such as Fengyun series of artificial satellites and Long March series of carrier rockets for temperature control and heating system.

2. Military equipment:in the Dongfeng, Red Flag and other series of missiles, as well as aircraft, ships, tanks, artillery gyroscopes, accelerometers, fire-control radar and other equipment, PI heating film heaters also play an important role.

3. Scientific analytical instruments:to provide a constant temperature source for thermal conductivity (or warmth factor) measuring instrument, stabilize the working temperature of optoelectronic components.

4. Medical Instruments:In the health care and beauty equipment industry, PI heating film is used as a heating element because of its stability and safety.

5. Automotive industry:used in automotive rearview mirror defroster, antenna or radar snow removal, defrost heating element and speed control resistor sheet.

6. Flexible electric heating elements:PI heating film is used in flexible electric heating elements and low-voltage wearable devices because of its flexibility and high temperature resistance.

| Dielectric strength | UDC 500V ≥ 200MΩ |

| Electrical resistance | UAC ≥ 2000 V |

| Operating temperature | Long-term use ≤ 232 ℃ |

| Weight | ≤ 278 g/m² |

| Heat flow density (without heat sink and temperature control) | ≤ 1.1W/cm² |

| Heat flow density (with heat sink and temperature control) | ≤ 6.5W/cm² |

| Thickness | ≤ 0.20 mm |

| Power | Variable according to the specific application, need to provide electrical parameters such as voltage, resistance, etc. |

| Outside lead position | According to specific design |

| Direction of outer lead | According to specific design |

| Outer lead length | According to specific design |

| Thermal conductivity | Excellent |

| Resistance stability | Excellent |

What is PI Heating Film?

PI heating film is a type of heating film that uses a polyimide (PI) material as a substrate to generate heat when an electric current is passed through the heating element, and is widely used in heating applications.

How does PI heating film work?

Current is passed through a heating element (such as a resistance wire) embedded in the PI film, and the excellent thermal conductivity of the PI material is utilized to achieve uniform heating.

What are the main advantages of PI heating film?

The main advantages include high temperature resistance, excellent flexibility, uniform heating, chemical resistance and high durability.

How high of a temperature can PI heating film withstand?

PI heating film can typically withstand temperatures up to 232°C, depending on the thickness and design of the film.

What are the applications for PI heating film?

Applications include electronic equipment, automotive heating, medical equipment, industrial heating, aerospace, and more.

What is the main material of PI heating film?

The main material is polyimide (PI), a polymer material with excellent high temperature resistance.

How to install PI heating film?

PI heating film is usually installed on the surface to be heated by adhesive or hot pressing technique to ensure good heat transfer and electrical connection.

What is the chemical resistance of PI heating film?

PI materials have excellent chemical resistance and are resistant to a wide range of chemicals.

How to maintain PI heating film?

Regularly check electrical connections to avoid overheating, keep membrane surfaces clean, and prevent mechanical damage.

What are the advantages of PI heating film over other heating films (e.g. silicone heating film)?

Compared to silicone heating film, PI heating film has higher temperature resistance and better chemical resistance, but may be slightly less flexible and adaptable.

Previous: PET Heating Film

Next: Tubular Heater

Contact

No. 1, 1st Road, Mawu Industrial Zone, Qiaoli, Changping Town, Dongguan City, Guangdong Province

Email:

Phone:

+86 136-2001-9955

+86-0769-83488762-8016