In modern industrial and home heating equipment, Aluminum Foil Heaters are an important choice in the field of energy saving due to their unique design and high performance.

1. High efficiency heat conversion rate

One of the core advantages of Aluminum Foil Heaters is their excellent thermal conversion rate. Aluminum foil material has excellent thermal conductivity and is able to quickly and evenly convert electrical energy into heat. Compared to conventional heaters, Aluminum Foil Heaters have less heat loss, effectively reducing heat waste. This efficient heat conversion mechanism means that the heater can reach the target temperature in a shorter period of time, thus reducing overall energy consumption.

2. RaPId warming and uniform heating

Aluminum foil heaters are designed to warm up quickly and provide uniform heat distribution. Due to the thermal conductivity of aluminum foil, the heater achieves uniform temperature distribution in a very short period of time, avoiding the hot and cold spots that are common with conventional heaters. This uniform heating reduces temperature fluctuations, which reduces energy consumption during the heating process and improves heating efficiency.

3. Low power design

Many aluminum foil heaters are designed with low power consumption, which not only reduces energy consumption, but also effectively lowers operating costs. Low-power design usually involves optimizing the resistor material and improving the circuit layout to ensure that the heater consumes less power while providing sufficient heat. This design not only helps to save energy, but also reduces the operating temperature of the equipment and extends its service life.

4. Precise temperature control

Aluminum foil heaters are usually equipped with high-precision temperature control systems that can precisely regulate and maintain the desired temperature. Precise temperature control can avoid overheating and thus reduce energy waste. Users can set the temperature according to the actual demand, avoiding unnecessary energy consumption and further improving the overall energy-saving performance of the heater.

5. Low radiant heat loss

The design of aluminum foil heaters is also characterized by low radiant heat loss. The smooth surface of the aluminum foil effectively reflects and transfers heat, reducing heat loss by radiation. This means that more heat is effectively utilized on the heating target rather than dissipated into the surrounding environment, thus further improving energy efficiency.

6. Flexible application design

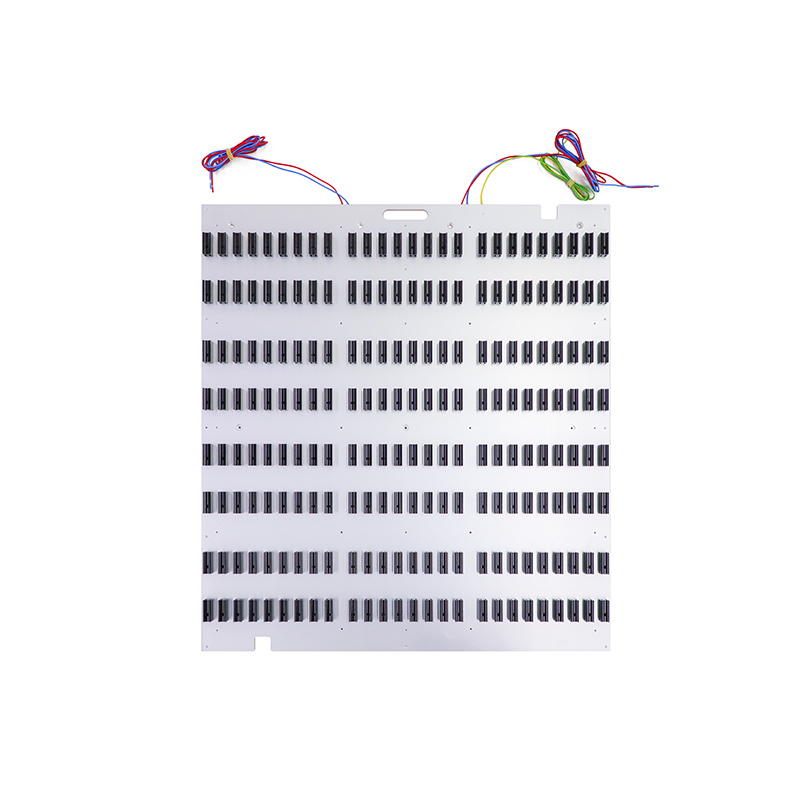

The flexible design of aluminum foil heaters allows them to be adapted to a wide range of application scenarios and optimized for specific needs. In customized designs, size, shape and power can be adjusted to specific heating needs. This flexibility allows the aluminum foil heater to achieve optimal energy utilization in different application environments, avoiding unnecessary energy waste.

Aluminum foil heaters demonstrate significant energy savings due to their efficient heat conversion, fast temperature rise, low power consumption design and precise temperature control. Through optimized design and materials, aluminum foil heaters are able to provide stable and uniform heating while reducing energy consumption, making them an important choice for modern energy-efficient heating technology. These features not only help to reduce operating costs, but also enable more efficient energy utilization in practical applications.