In modern industries, heating processes are integral to operations across various sectors, from food processing and cheMical treatment to medical device manufacturing. Standard heaters may not always provide the performance and efficiency needed to meet specific application requirements. This is where customized tubular heaters come into play, offering tailored solutions to meet the diverse and complex heating demands of different industries.

The Advantages of Customized Tubular Heaters

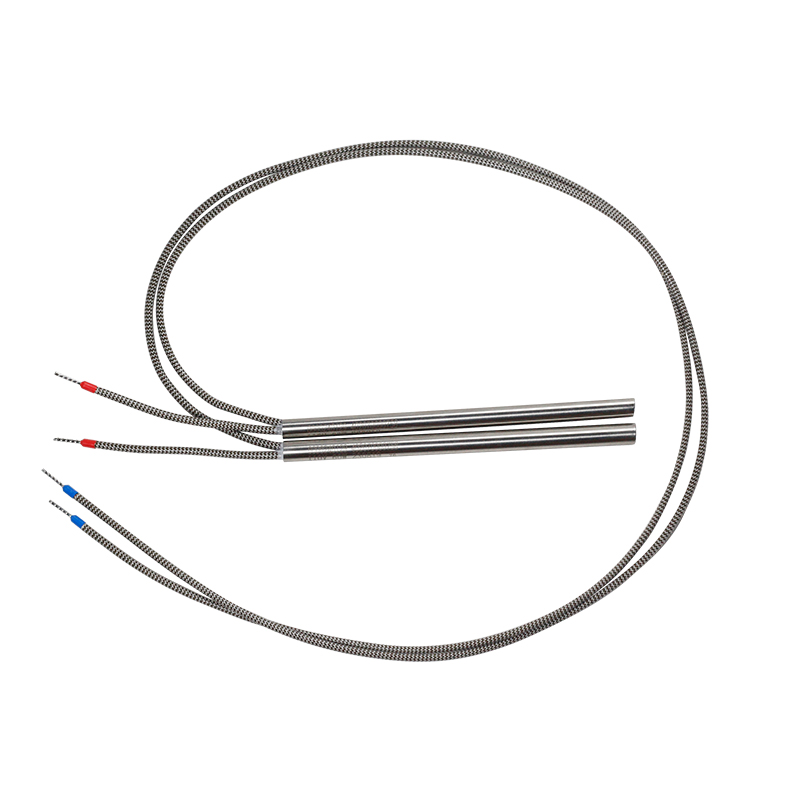

The primary advantage of customized Tubular Heaters is their flexibility and adaptability. Different industrial applications often have varying requirements, such as temperature ranges, heating speeds, material compatibility, and environmental conditions. Customized designs allow these heaters to be tailored to specific needs, ensuring they operate under predefined conditions and deliver optimal results.

Precision Heating in Food Processing

The food processing industry demands precise temperature control, as even minor temperature variations can impact the quality and safety of the final product. Customized Tubular Heaters can be designed to meet the specific needs of food processing, ensuring accurate temperature regulation. For example, in pasteurization processes, heaters must maintain a stable temperature to eliminate harmful microorganisms while preserving the flavor and nutritional value of the food. Through customized design, the heater's shape, power density, and material can be optimized to deliver the required heating effect in specific positions along the production line.

Durability and Efficiency in Chemical Processing

In the chemical processing industry, tubular heaters must withstand harsh environments, including exposure to corrosive chemicals, high temperatures, and pressures. These applications require heaters that not only provide efficient heating but also possess exceptional durability. Customized tubular heaters can be made from specialized materials such as nickel alloys or corrosion-resistant stainless steel to ensure long-term reliability in challenging environments. Additionally, based on specific processing needs, the design can include multi-zone control to achieve precise temperature distribution, ensuring uniform chemical reactions and maximum efficiency.

Safety and Reliability in Medical Devices

Heating applications in medical devices demand high safety and reliability, especially when heating patient fluids or medications. Customized tubular heaters can be designed to meet the strict standards of the medical industry, ensuring they provide precise heating without posing any risks to patients or operators. For instance, in the design of blood heaters, customized tubular heaters can ensure even heating, preventing the formation of hot spots while incorporating features like automatic shut-off and overheat protection to prevent accidents.

Custom Solutions for Complex Needs

Customized tubular heaters not only meet the basic requirements of special applications but also enhance performance through the integration of intelligent control systems and advanced sensing technology. For example, in applications requiring precise temperature control, heaters can be equipped with accurate temperature sensors and smart controllers to monitor and adjust heating power in real time, ensuring temperature stability and consistency.Moreover, the shape and size of customized heaters can be adjusted according to specific installation requirements. In cases where space is limited or specific installation methods are required, tubular heaters can be designed in sPIral, U-shaped, or other complex forms to fit perfectly within the system, ensuring seamless integration and optimal heating performance.

Customized tubular heaters, with their flexible design and precise performance, are ideal solutions for meeting various special heating needs. Whether it's temperature control in food processing, durability in chemical processing, or safety in medical devices, customized tubular heaters provide accurate, efficient, and reliable heating solutions. As industrial technology continues to advance, customized tubular heaters will play an increasingly important role in various fields, offering high-quality heating support for complex applications.