Silicone Rubber Heaters are highly suitable for use in equipment like powder coating machines, especially in powder coating and other powder handling processes. Their unique advantages make them an ideal choice for this application. Below, we explore why silicone rubber heaters are a perfect fit for powder coating machines.

Why Silicone Rubber Heaters Are Ideal for Powder Coating Machines

1. Even Heating

One of the main advantages of silicone rubber heaters is their ability to provide uniform heat across the surface. This is crucial in powder coating applications, where maintaining an optimal temperature is essential for the proper flow and adhesion of the coating. Uneven heating can lead to hot spots that affect the quality of the coating or cause inconsistent results. Silicone rubber heaters ensure that the entire surface is heated evenly, preventing such issues.

2. Flexibility and Customization

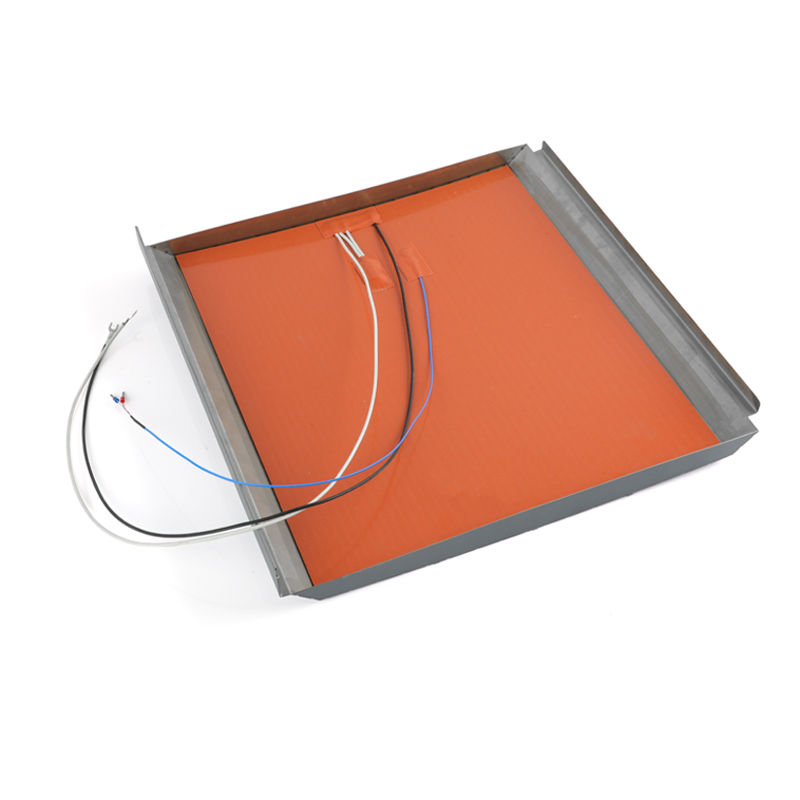

Silicone rubber heaters are known for their flexibility, making them easy to customize for a wide range of shapes and sizes. This flexibility allows the heaters to wrap around complex and irregularly shaped surfaces, such as powder storage bins or spray nozzles. The ability to customize the heaters ensures that they fit perfectly and provide consistent heating, even in tight or irregular spaces within the powder coating machine.

3. High-Temperature Resistance

Powder coating machines often require high temperatures to ensure the proper curing and application of the powder coating. Silicone rubber heaters are capable of withstanding high temperatures, tyPIcally up to 200°C, making them suitable for the intense heat required in these machines. This temperature tolerance ensures the stability of the heating process and prevents overheating, allowing the equipment to function reliably.

4. Energy Efficiency

Silicone rubber heaters are energy-efficient, offering direct heating to the required surfaces. Unlike other heating methods that may waste energy through convection or radiation, silicone rubber heaters focus heat exactly where it is needed, reducing energy consumption. This can result in lower operating costs, especially in machines that run for extended periods, such as powder coating systems.

5. Corrosion and Moisture Resistance

Powder coating machines often operate in environments with high dust levels, moisture, or exposure to cheMicals. Silicone rubber heaters are highly resistant to corrosion, moisture, and various chemicals, making them ideal for these harsh environments. Their durability ensures that the heaters perform reliably and maintain their effectiveness, even when exposed to challenging conditions.

6. Easy Installation

The flexible nature of silicone rubber heaters makes them easy to install, even in complex and confined spaces. Their thin profile and lightweight design make it simple to fit them into areas where rigid heating Elements might not be suitable. Installation is quick, and maintenance is less complicated, providing significant benefits for machine operators and technicians.

Applications in Powder Coating Machines

Heating Powder Storage Bins: Silicone rubber heaters can be used to heat powder storage bins, ensuring the powder flows smoothly and doesn't clump or solidify. This ensures that the powder can be easily applied during the coating process.

Heating Spray Equipment: These heaters can be applied to the pipes or nozzles of powder spray equipment to maintain consistent powder flow during the spraying process. This helps to ensure even coating and prevent issues related to clogging or uneven application.

Temperature Control: Silicone rubber heaters help regulate the temperature of the powder coating machine, preventing overheating or underheating. Maintaining a constant temperature is crucial to achieving consistent powder coating results.

Preventing Powder Clumping: When the temperature is too low, powder can clump or become difficult to apply. Silicone rubber heaters ensure that the temperature remains consistent, preventing clumping and ensuring smooth application.

Silicone rubber heaters offer an efficient, flexible, and durable solution for powder coating machines. Their ability to provide even heating, resistance to harsh environments, energy efficiency, and easy installation make them the ideal choice for this application. By using silicone rubber heaters, powder coating machines can achieve consistent, high-quality results while reducing energy consumption and maintenance costs. Their versatility and effectiveness make them an indispensable part of the powder coating process.