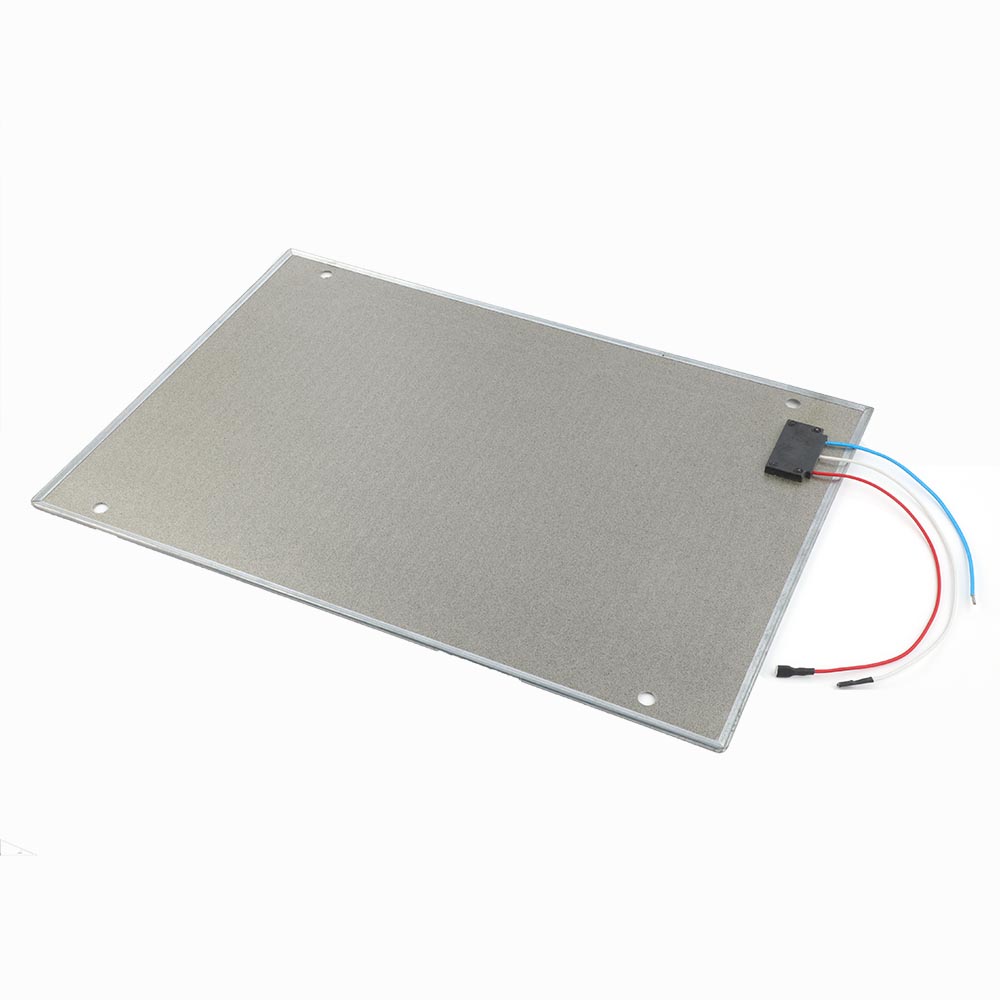

Mica Heater Sheet is a high-efficiency, high-temperature resistant heating element made of mica material combined with metal alloy. It is widely used in industrial heating equipment, home appliances, personal care, medical equipment and other fields. Its high temperature tolerance can reach 850℃, heating is uniform and efficient, and it has a long life and high safety. It is suitable for various customized requirements such as size, voltage and power, providing flexible solutions to meet the needs of different application scenarios.

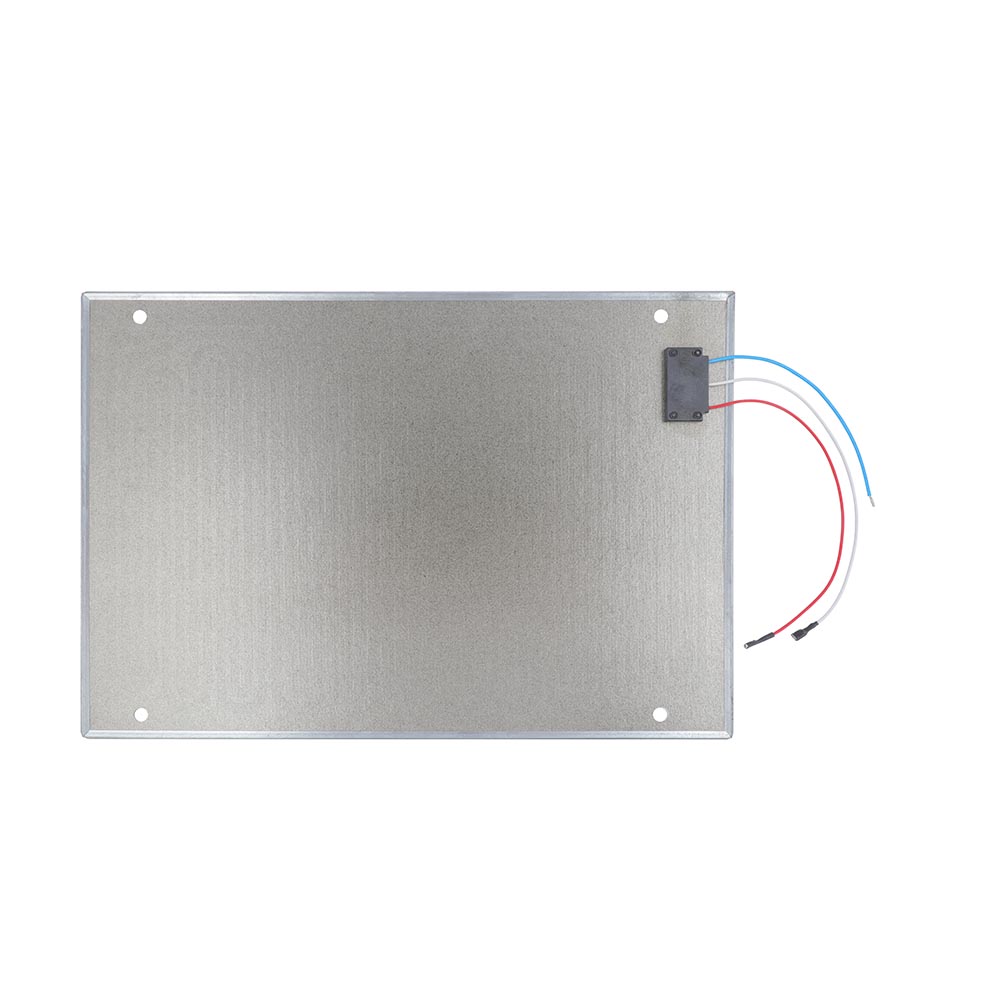

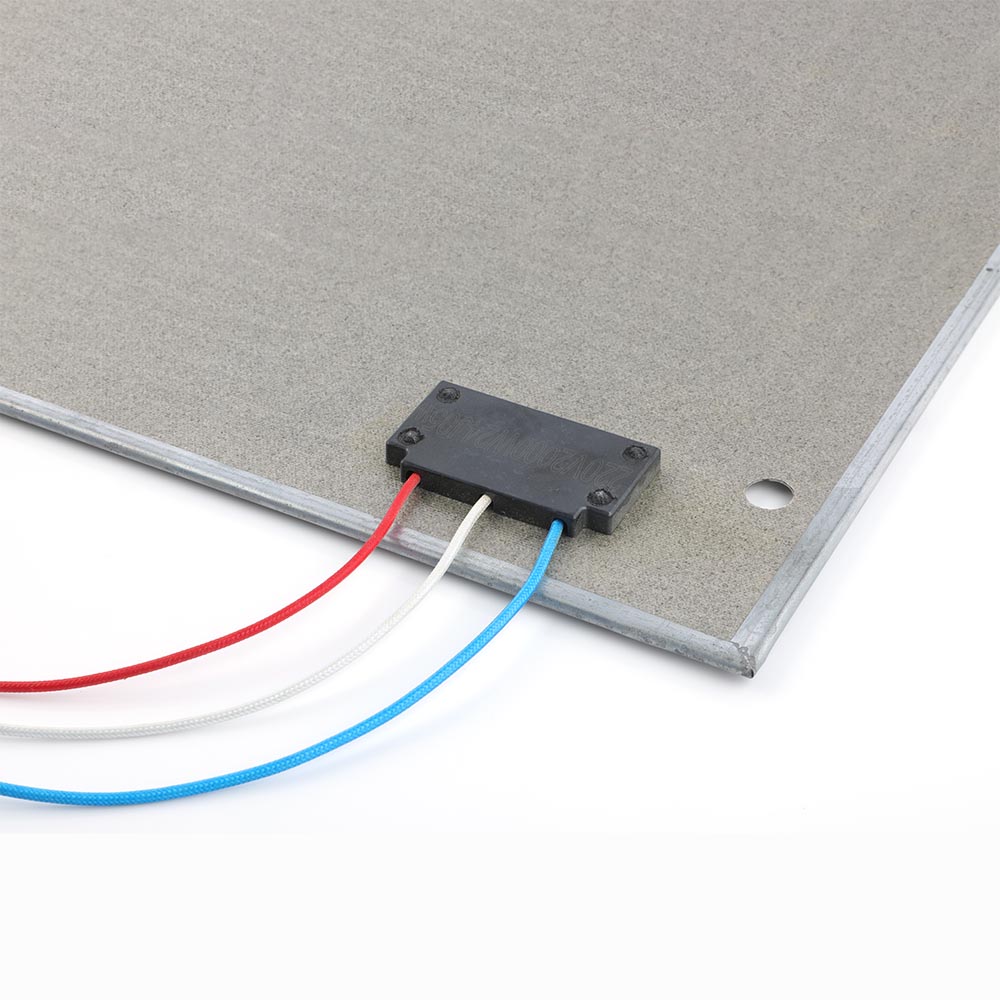

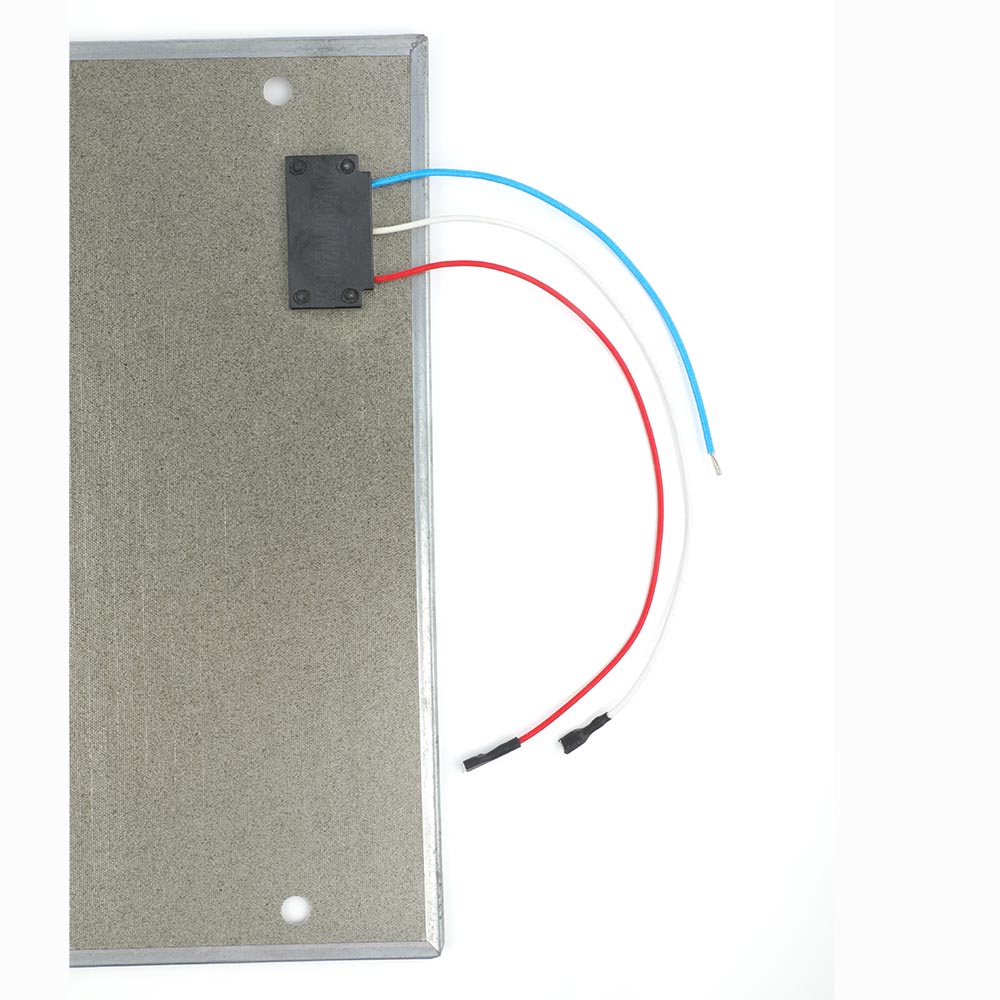

Mica Heater sheet, also known as mica heating film, is a flat electric heating element made by forming a resistance circuit from special metal foil (10–50 microns thick) and laminating it between two layers of mica insulation. The insulation material can be selected based on the required heating temperature and working environment. The size can be customized, ranging from a few square millimeters to several square meters.

1. High Operating Temperature

High-temperature models of Mica Heater elements can reach up to 850°C, making them suitable for extreme thermal environments.

2. Surface Heating with High Efficiency and Energy Saving

As a flat surface heating element, Mica Heater film maximizes contact with the heated object, providing excellent heat transfer without an open flame. This results in thermal efficiency rates of around 90%, reducing heat loss and power consumption significantly.

3. Long Lifespan

Compared to traditional electric heating wire elements, mica heater sheets offer up to 10 times longer service life.

4. Flexible Shapes and Wide Applications

With a typical thickness of around 0.8mm, custom mica heaters can be made in various shapes and sizes, widely used in heating devices, curling irons, straighteners, heating cups, heating plates, medical care devices, instruments, and household appliances.

5. Safe and Flame-Free Heating

Mica heating film operates without open flames, ensuring safe usage even in close-contact applications. Low-voltage mica heating elements are safe for direct skin use, and voltage tolerance can reach up to 380V.

6. Strong Corrosion Resistance

With metal foil sealed within the mica insulation, the electric heater film resists chemical gases, liquids, and particle radiation, providing durable protection in harsh environments.

7. Integrated Circuit Control

The heating unit can be designed with built-in fast-heating circuits, insulation holding circuits, and temperature control circuits, enabling smart and automated thermal regulation.

8. Accurate Temperature Control and Low Thermal Inertia

The temperature control accuracy is within ±2%, offering quick response and precise performance.

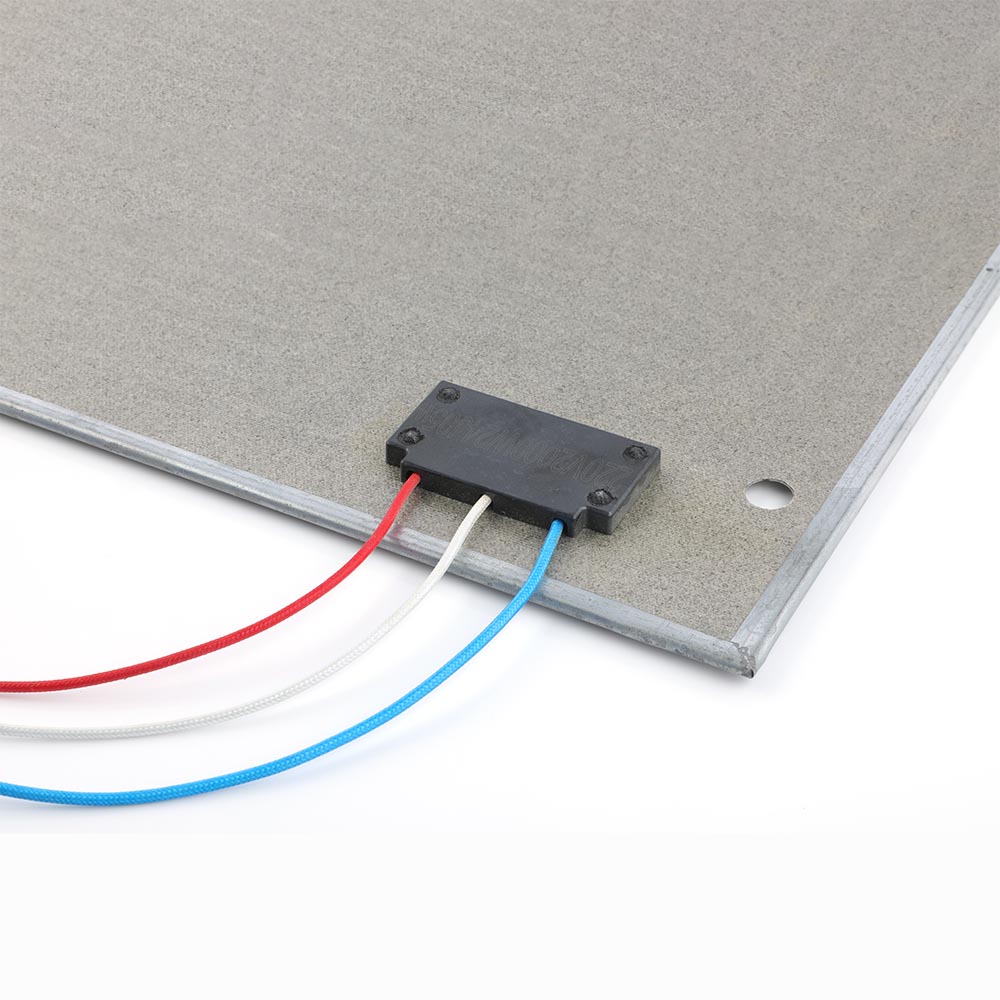

9. Easy Installation and Wiring

Lead wires can be riveted onto the element, and the mica heating element can be fixed to the surface by adhesive or mechanical methods, making it adaptable to a wide range of use cases.

| Parameter | Specification |

|---|---|

| Input Voltage | 1V–380V, or customized according to customer requirements |

| Insulation Material | Mica sheet |

| Heating Material | OCr25Al5A (Iron-Chromium-Aluminum alloy) |

| Temperature Resistance | <350–500°C |

| Power | Customizable based on customer requirements |

| Dimensions | Custom shapes and sizes available to meet specific customer needs |

| Thickness | Total product thickness ≥ 0.6mm |

| Features | Double-sided heating, uniform heat distribution, certain radiation capability, high heating efficiency. Options include single-sided or double-sided heating. Voltage, power, and lead wire layout customizable. |

Mica Heater Sheet Application Field

Mica Heater Sheet Application FieldMica heater sheet is widely used in many fields for its high temperature resistance, uniform heating and reliable safety:

1. Industrial heating equipment

Heating furnace, heat treatment equipment: used for heating and processing of metal, plastic and other materials.

Mold heating: used for heating molds in processes such as plastic injection molding and casting.

2. Home appliances

Electric cups, insulation plates: used for home heating equipment, providing efficient and uniform heating effect.

Oven heater: provides a stable and reliable heating source to ensure uniform heating of food.

3. Personal care and beauty

Beauty equipment, heater: used for hair care, electric heating skin care device, etc., providing gentle and efficient heat.

Massager, hot compress equipment: can be used for health and restorative hot compress to improve comfort.

4. Medical equipment

Physical therapy equipment: used for hot compress application in treatment equipment, which helps to accelerate the recovery process.

Medical instrument heating: maintain a stable working temperature of certain medical equipment.

5. Transportation

In-vehicle heating equipment: such as in-vehicle heaters, temperature control systems, etc., suitable for cars and other transportation.

Aircraft and train heating equipment: provide a stable heating source to ensure the comfort of passengers.

What is the operating temperature range of Mica heating plates?

The operating temperature of high-temperature mica heating film elements can reach 850℃, which is suitable for high-temperature heating applications.

Can I customize the size and voltage of mica heating plates according to my needs?

Absolutely. We support customized size, voltage (from 1V to 380V), power, etc. to ensure that your specific needs are met.

Is the mica heating plate safe? Will there be open flames?

Mica heating plates have no open flames and are very safe and reliable. Due to its insulation, it will not cause electric shock or fire risks when used, and is suitable for home and industrial use.

What is the service life of mica heating plates?

The service life of mica heating plates is far longer than that of traditional electric heating wire heating elements, about 10 times more. Its durability makes long-term use possible, especially for industrial applications.

What is the heating efficiency of mica heating plates?

Mica heating plates use a planar heating method, which has an efficient and uniform heating effect, and the thermal efficiency can be as high as 90%, making it an ideal choice for energy saving and environmental protection.

How is the mica heating plate installed?

Mica heating plates can be installed by pasting, mechanical fixing or screw installation, which is convenient and quick.

Can mica heating plates resist corrosion and chemicals?

Yes, the components of mica heating plates are safely enclosed in an insulating layer, which can effectively resist the corrosion of chemical gases and solutions, and have strong radiation resistance.

Is there a minimum order quantity and delivery time limit?

We support small batch customization, and the delivery time is usually 7-15 days. The specific delivery time depends on the order quantity and complexity.

Previous: Carbon Fiber Heating Pad for Gloves

Next: Graphene Heated Insoles

Contact

No. 1, 1st Road, Mawu Industrial Zone, Qiaoli, Changping Town, Dongguan City, Guangdong Province

Email:

Phone:

+86 136-2001-9955

+86-0769-83488762-8016