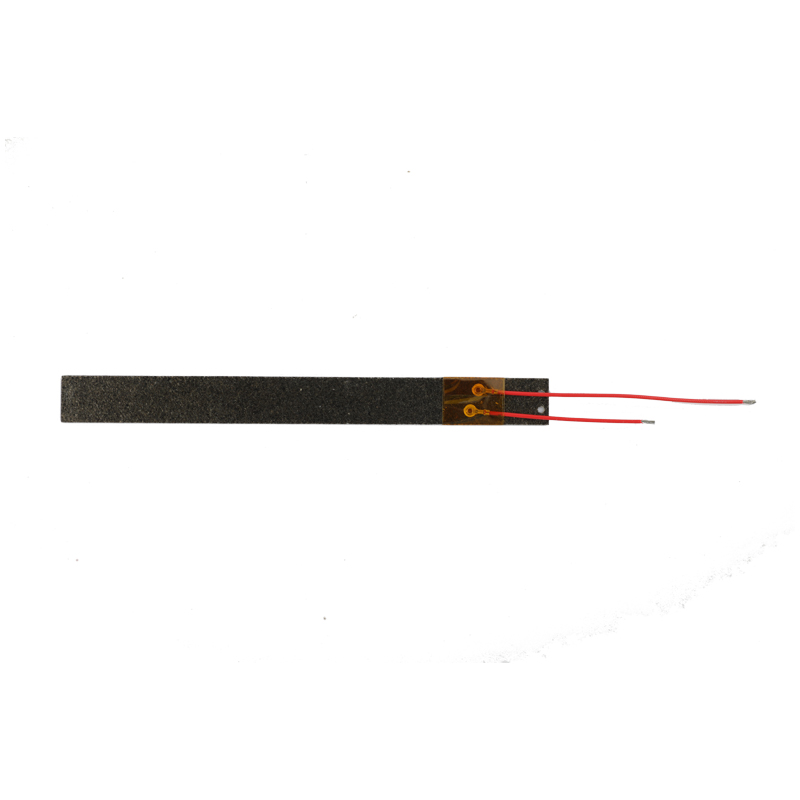

Mica Heating Element is a highly efficient heating component widely used in industrial heating applications. Known for its excellent thermal stability, electrical insulation properties, and resistance to high temperatures, mica heating elements are the preferred choice for many high-temperature heating systems.

A Mica Heating Element consists of high-quality mica material, with heating resistance wire (such as nichrome or iron-chromium alloy) wound around a mica base. When electrical current passes through the resistance wire, it generates heat, which is transferred to the mica surface. Due to its excellent electrical insulation properties, mica allows these Heating Elements to operate in high-temperature environments and ensures a long service life.

High Temperature Resistance: Mica Heating Elements can operate at temperatures up to 600°C or higher, making them suitable for high-temperature environments where stable heating is essential.

Excellent Insulation: Mica offers outstanding electrical insulation, preventing electrical leakage and ensuring safe operation.

Uniform Heating: The precise design of the resistance element allows for uniform heat distribution, preventing hotspots and uneven heating.

Compact Design: Mica heating elements are typically compact, making them suitable for space-limited applications.

Corrosion Resistance: Mica's natural resistance to acids, alkalis, and chemicals ensures long-term durability even in harsh environments.

element mica are widely used in various industries due to their excellent heat stability and performance:

Industrial Equipment: Used in applications such as metal processing, plastic molding, and other high-temperature industrial heating systems.

Home Appliances: Commonly found in electric water heaters, ovens, and electric stoves.

Laboratory Equipment: Used in laboratory drying ovens, heat treatment furnaces, and other heating devices.

Food Processing: Found in baking equipment, fryers, and other food preparation machinery.

Product Specification Table for Mica Heating Elements:

| Parameter | Specification |

|---|---|

| Material | Mica (Natural Mica Sheet) |

| Heating Element | Nichrome, Iron-Chromium Alloy Wire |

| Operating Temperature | Up to 600°C (depending on model) |

| Power Range | From 100W to 5000W (customizable) |

| Voltage Options | 110V, 220V, 380V, or customized |

| Insulation Resistance | High insulation resistance at high temperatures |

| Shape | Flat, Cylindrical, Custom shapes available |

| Size | Customizable based on customer requirements |

| Mounting | Screw Mount, Bracket Mount, Custom Mounting |

| Thickness | Typically 1-5mm (customizable) |

| Dimensions | Custom dimensions based on application |

| Corrosion Resistance | Excellent resistance to acids, alkalis, and chemical exposure |

| Lifespan | Long life expectancy, typically 10+ years |

| Application | Industrial heating, Laboratory equipment, Home appliances, Food processing |

| Safety Certifications | CE, RoHS, UL (varies by model and region) |

| Customization Options | Power, Voltage, Size, Shape, Mounting method |

| Working Environment | Dry, well-ventilated environments, suitable for high-temperature settings |

| Warranty | Typically 1-2 years depending on the manufacturer |

Operating Temperature Range: Typically ranges from 450°C to 600°C, depending on the specific model and application.

Power Range: Can be customized to meet specific needs, with typical ranges from several watts to several kilowatts.

Voltage: Suitable for various voltage requirements, including 110V, 220V, 380V, etc.

Materials: Mica base with nichrome or other special metal alloys for the heating element.

Mica heating elements can be customized to meet the specific requirements of different applications:

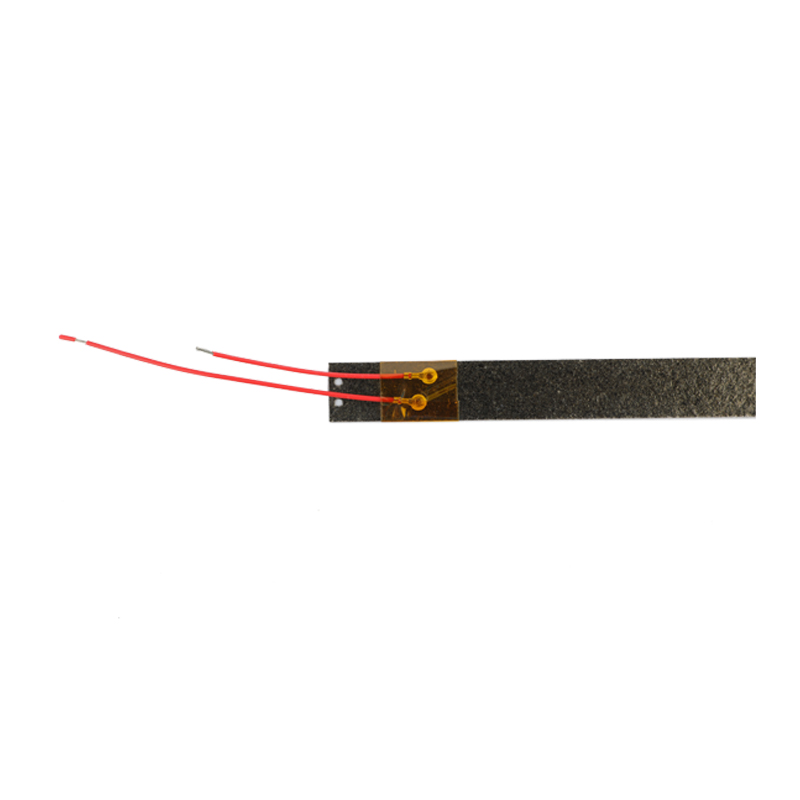

Size and Shape: Custom dimensions and shapes can be manufactured to fit specific equipment and installation requirements.

Power and Voltage: Configurations can be tailored to meet particular power and voltage needs for different devices.

Mounting Methods: Options such as screw mounting, bracket installation, or custom fixtures for ease of integration into various systems.

FAQ

A Mica Heating Element is a heating component made from high-quality mica, typically combined with a resistance wire such as nichrome or iron-chromium alloy. It is used in various heating applications, particularly in environments that require high temperatures and electrical insulation.

A Mica Heating Element works by passing electrical current through a resistance wire, which generates heat. This heat is transferred to the mica sheet, which acts as an insulating and heat-dispersing medium, ensuring that the element heats evenly and safely.

The key advantages of Mica Heating Elements include:

High Temperature Resistance: Can withstand temperatures up to 600°C or higher.

Durability: Long lifespan, often exceeding 10 years of operation.

Excellent Insulation: Provides excellent electrical insulation, reducing the risk of electrical leakage.

Even Heat Distribution: Ensures uniform heating across the surface.

Corrosion Resistance: Resistant to acids, alkalis, and other chemical agents.

Mica Heating Elements are widely used in:

Industrial applications: Such as metal processing, plastic molding, and drying equipment.

Home appliances: Including electric water heaters, ovens, and stoves.

Laboratory equipment: Such as drying ovens and heat treatment furnaces.

Food processing: For equipment like baking ovens and fryers.

A Mica Heating Element can typically operate at temperatures up to 600°C, though the exact limit may vary depending on the specific design and materials used.

Previous: Far Infrared Heating Film

Next: Silicone Rubber Heaters

Contact

No. 1, 1st Road, Mawu Industrial Zone, Qiaoli, Changping Town, Dongguan City, Guangdong Province

Email:

Phone:

+86 136-2001-9955

+86-0769-83488762-8016