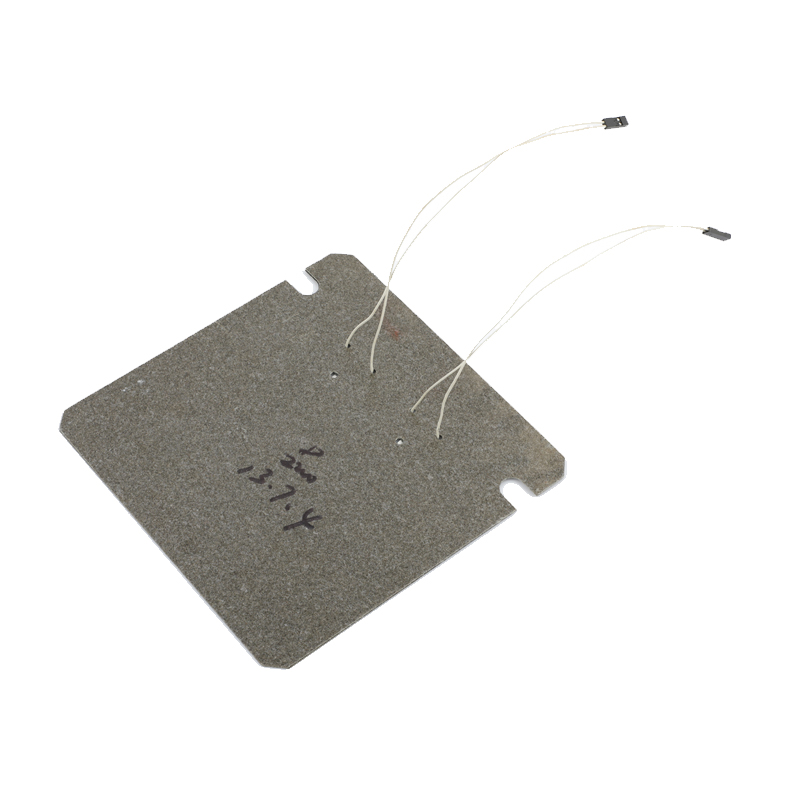

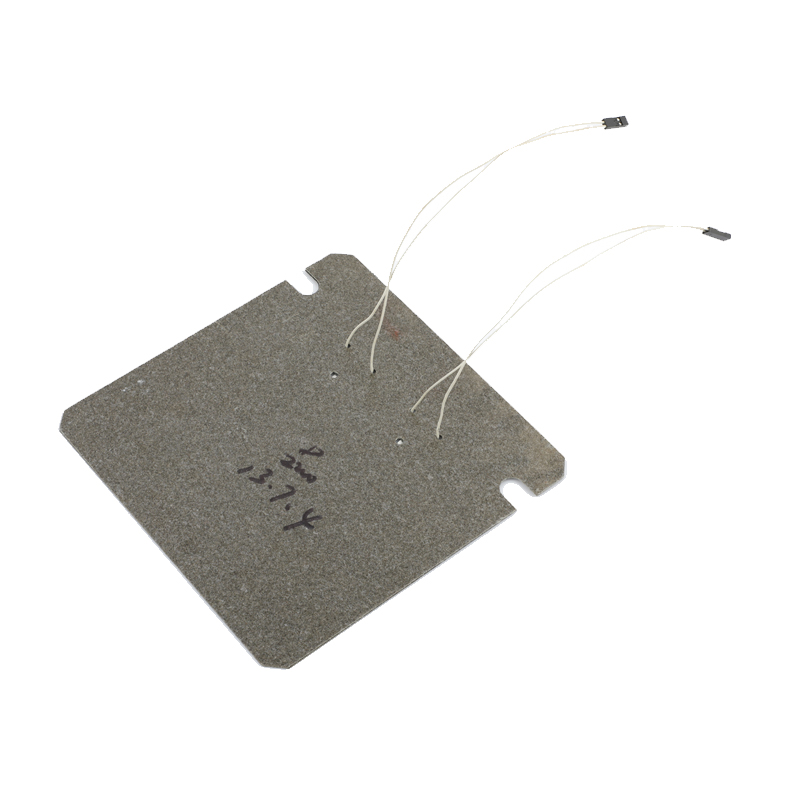

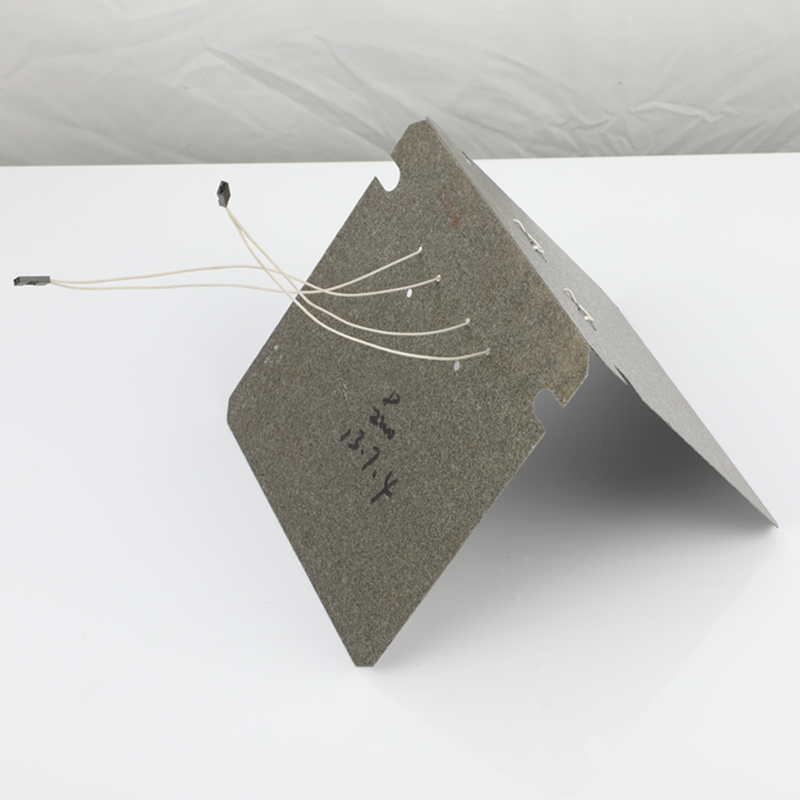

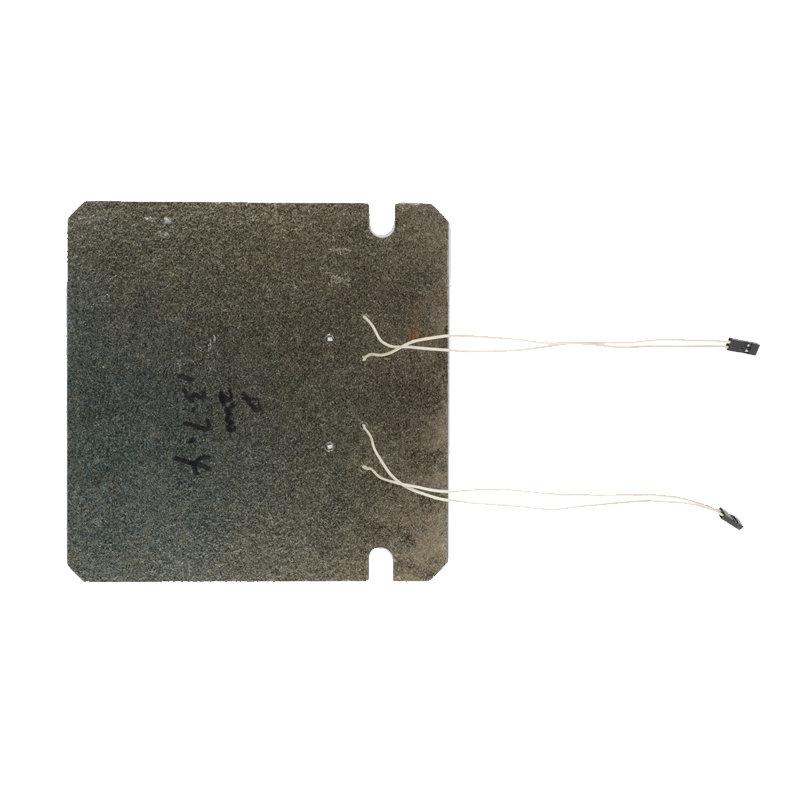

Mica Plate Heater is a reliable, efficient and widely used heating element for all types of high temperature industrial equipment. It plays an important role in many industries, such as plastics processing, food processing, laboratory equipment, etc., thanks to its excellent thermal conductivity, insulation and resistance to high temperatures. With a wide range of customization options, the Mica Plate Heater can be individually designed to meet the needs of different applications, ensuring optimal performance in a variety of environments.

The Mica Plate Heater is an efficient, compact and durable electric heating element used in a wide variety of industrial applications, especially in equipment requiring uniform high temperature heating. Its core material is Mica (Mica), which has excellent insulating properties and thermal conductivity, making it stable and safe for high-temperature operation.

Product Features

1. High Temperature Capability:Mica Plate Heaters have excellent high temperature capability, capable of continuous operation at temperatures up to 600°C (1112°F). This makes them ideal for industrial processes that require high temperature heating, such as plastics molding and food processing.

2. Uniform Heating:The high thermal conductivity of mica ensures that the heating element produces uniform heat distribution during operation, eliminating the appearance of hot or cold spots and ensuring consistent temperatures throughout the heating zone. This uniform heating characteristic greatly improves the efficiency of the equipment and product quality.

3. Excellent Insulation:Mica is a natural electrical insulation material that maintains good insulation at high temperatures. This makes the Mica Plate Heater safe to work with and prevents electrical failures.

4. Rapid Heat-Up:Mica Plate Heater has an excellent heat-up rate, which can quickly reach the required working temperature in a short period of time, thus increasing the working efficiency and reducing the waiting time for heating.

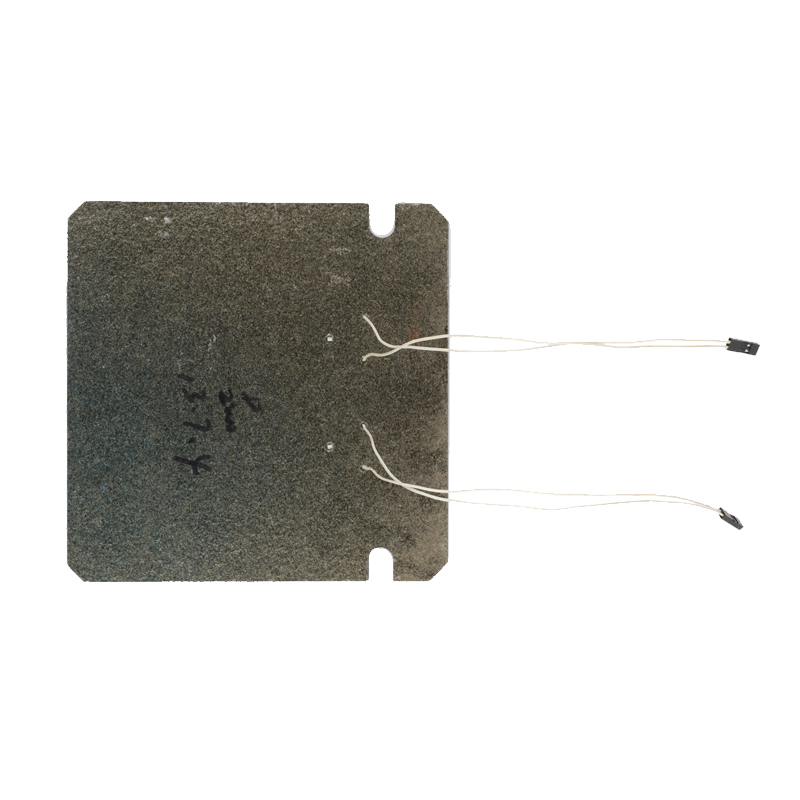

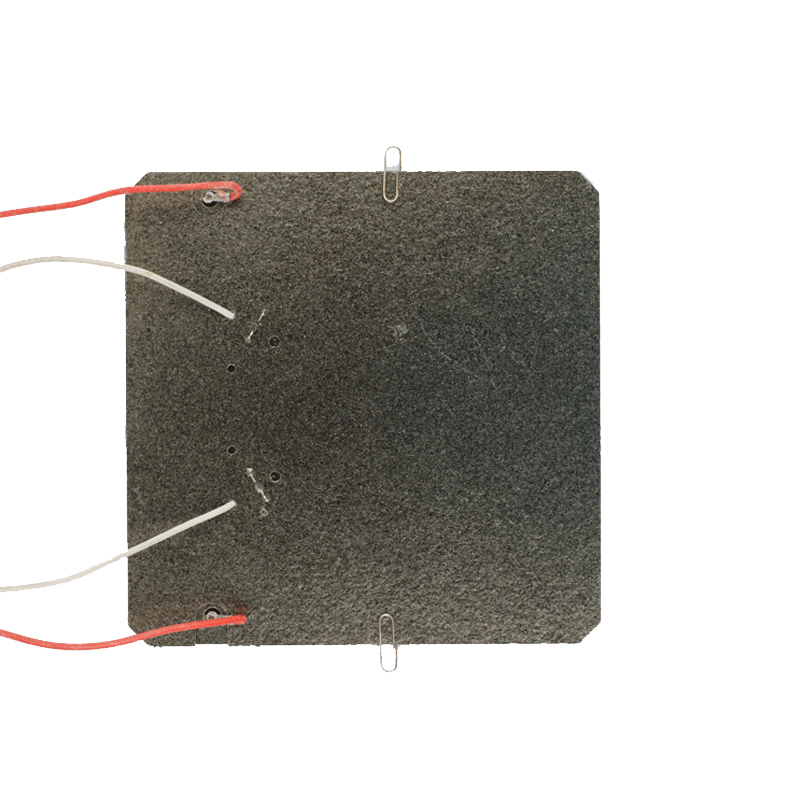

5. Compact design:The heater has a very compact design, usually between 3-5 mm thick, suitable for installation in equipment with limited space. Its thin and light construction makes it ideal for applications where a flat heating element is required.

6. Durability and reliability:Mica Plate Heater's shell is usually made of stainless steel or nickel-plated steel, which is highly resistant to corrosion and durability, and is able to cope with high temperatures, chemical corrosion, and vibration and other harsh environments, thus significantly extending the service life of the equipment.

Areas of application

The Mica Plate Heater is used in a wide range of industries, especially where precise, high temperature, uniform heating is required. These include the following industries:

1. Plastic processing industry:applied to plastic extruder, injection molding machine, blown film machine and other equipment, to ensure that the plastic material in the processing process to maintain a uniform heating temperature, improve product quality.

2. Food processing:used in ovens, heating plates, food baking equipment to ensure that food can be evenly heated to meet the productivity requirements.

3. Packaging equipment:In heat sealing equipment and shrink wrapping machines, Mica Plate Heater provides stable heating effect to ensure the packaging process goes smoothly.

4. Laboratory and medical equipment:In laboratory equipment (such as heating plates, laboratory ovens) and medical equipment, to ensure that the equipment in the precise temperature control conditions, to improve the accuracy of experiments and treatment.

5. Vacuum equipment:For heating needs in vacuum systems, adapting to the special conditions of oxygen-free and water-free environments.

6. Semiconductor Manufacturing:Used in the production of semiconductors and electronic components to provide a precise and controlled heating environment.

Customized Options

The Mica Plate Heater offers a wide range of customization options to meet the needs of different customer applications:

1. Voltage and power customization:Depending on the electrical requirements of the specific equipment, heaters with different voltages (e.g. 110V, 220V, 380V) and power densities can be supplied to ensure seamless integration with existing equipment.

2. Size and shape customization:Mica Plate Heater can provide a variety of sizes and shapes customized according to the installation requirements of the equipment, including rectangular, round, shaped, etc., to adapt to a variety of industrial applications.

3. Shell material customization:Different shell materials can be selected according to different working environments, such as stainless steel, nickel-plated steel, to ensure the service life of the heater in high-temperature, highly corrosive environments.

4. Additional protective layer:In order to improve durability and safety, customers can choose to add additional protective layer for the heater, such as coated ceramic layer or aluminum alloy shell, to further enhance the mechanical strength and corrosion resistance of the heater.

Installation and Use

1. Easy Installation:Mica Plate Heaters are usually designed for easy installation, supporting a variety of mounting methods, such as bolting, clamping, etc., to ensure that the heater can be tightly attached to the heating surface to provide the best heat transfer effect.

2. Safety in use:Due to the excellent insulating properties of mica, electrical safety is maintained even at high temperatures. The heater casing is carefully designed to prevent electrical faults or short circuits.

3. Easy maintenance:The heater's durable construction and material selection reduces the need for maintenance. Users only need to regularly check the electrical connections and surface cleaning to ensure its long-term stable operation.

Packaging and Transportation

1. Packaging:Each Mica Plate Heater undergoes strict quality inspection and is shipped in sturdy and durable packaging to ensure that it will not be damaged during transportation.

2. Delivery Time:Depending on the order quantity and customization requirements, the products are usually delivered within 2-4 weeks to ensure that customers can get the products and put them into use in time.

What is a Mica Plate Heater?

The Mica Plate Heater is an electric heater utilizing mica as the primary insulating material for high temperature resistance and uniform heating performance, often used in industrial applications where precise temperature control is required.

What is the operating temperature range of the Mica Plate Heater?

The Mica Plate Heater has a maximum operating temperature of 1112°F (600°C), making it suitable for continuous operation in high temperature environments.

What material does Mica Plate Heater use as insulation?

Mica Plate Heater uses natural mica as the main insulating layer, which has excellent electrical insulation properties and thermal conductivity, and remains stable at high temperatures.

What are the main applications of Mica Plate Heater?

It is widely used in the plastics processing industry, food processing, laboratory equipment, medical equipment, packaging equipment and semiconductor manufacturing where high temperature and uniform heating is required.

What is the typical thickness of Mica Plate Heater?

The Mica Plate Heater is typically between 3-5 mm thick, making it a compact design for installations where space is at a premium.

How can I customize the size and shape of the Mica Plate Heater?

Depending on the specific needs of the equipment, Mica Plate Heater can be customized in different sizes and shapes. Common shapes include rectangular, round, and shaped to fit a variety of industrial equipment installations.

How fast does the Mica Plate Heater heat up?

Mica Plate Heater heats up very quickly and can reach the required working temperature in a short period of time, thus improving work efficiency.

What are the housing material options for the Mica Plate Heater?

The housing of the Mica Plate Heater is usually made of stainless steel or nickel-plated steel to ensure long term durability in high temperature and corrosive environments. 9.

How does the Mica Plate Heater need to be maintained?

The Mica Plate Heater is simple to maintain. The user only needs to regularly check the electrical connections, clean the surfaces and ensure that there is no abnormal wear or damage to ensure that it operates reliably for a long period of time.

What voltage and power options does the Mica Plate Heater offer?

The Mica Plate Heater is available in different voltages and wattages depending on the customer's requirements. Typical voltages are 110V, 220V and power densities are typically between 1.5 - 6 W/cm².

Previous: Aluminium Heat Plate

Next: Epoxy Heating Plate

Contact

No. 1, 1st Road, Mawu Industrial Zone, Qiaoli, Changping Town, Dongguan City, Guangdong Province

Email:

Phone:

+86 136-2001-9955

+86-0769-83488762-8016