Epoxy Heater is a heating element that utilizes epoxy resin as a base material combined with conductive materials. It has excellent electrical insulation, chemical resistance, high temperature resistance, and good mechanical strength.

Epoxy heater is a kind of heating element made of epoxy resin material, which has good weathering and aging resistance, and as a surface insulating material can effectively prevent the product surface from cracking, and enhance the mechanical strength, so as to prolong the service life of the product. These heaters can be customized according to design requirements.

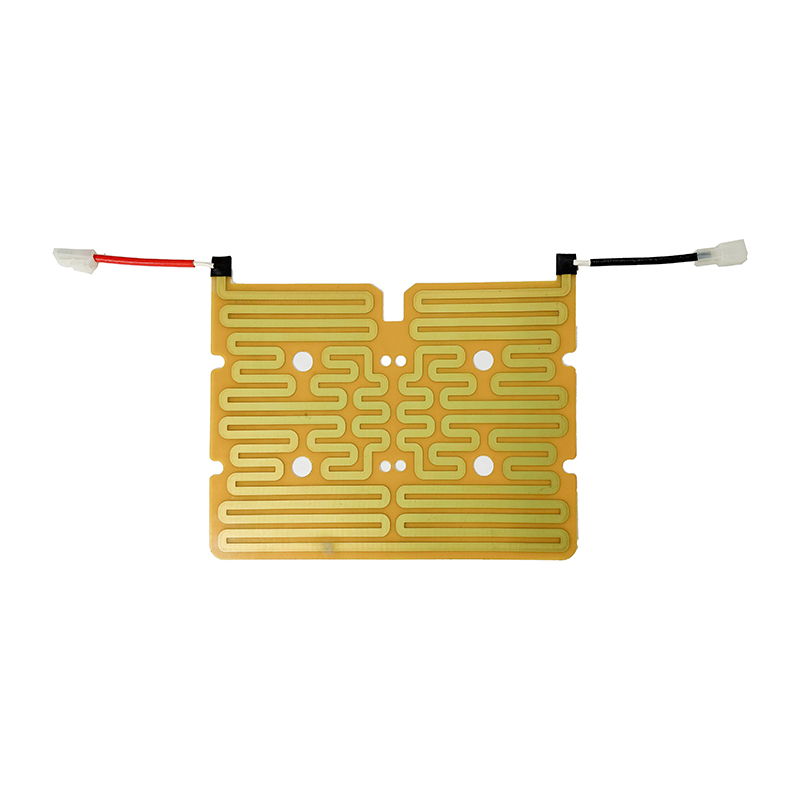

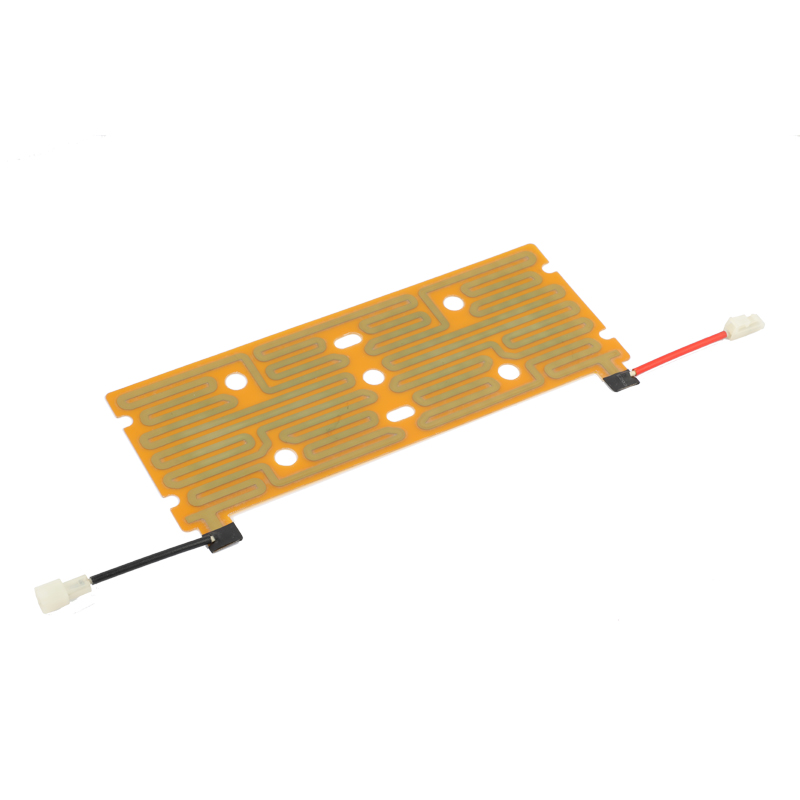

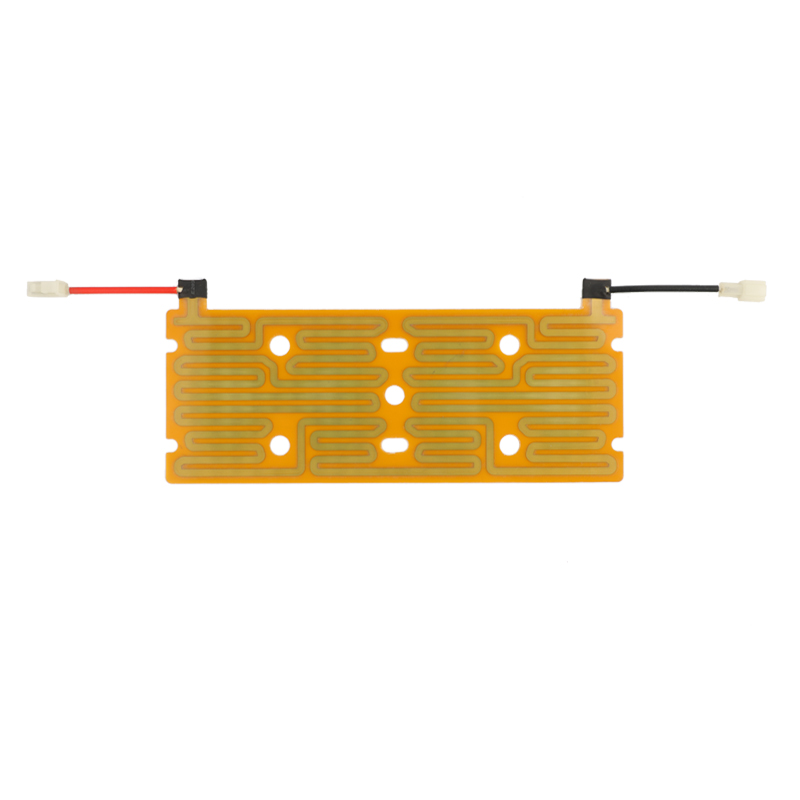

Product Characteristics

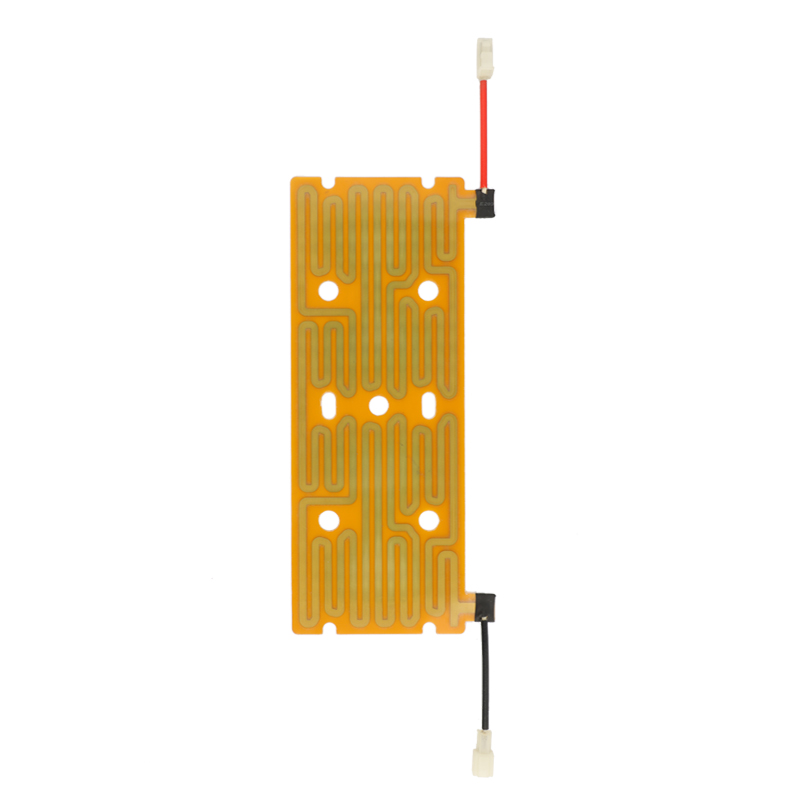

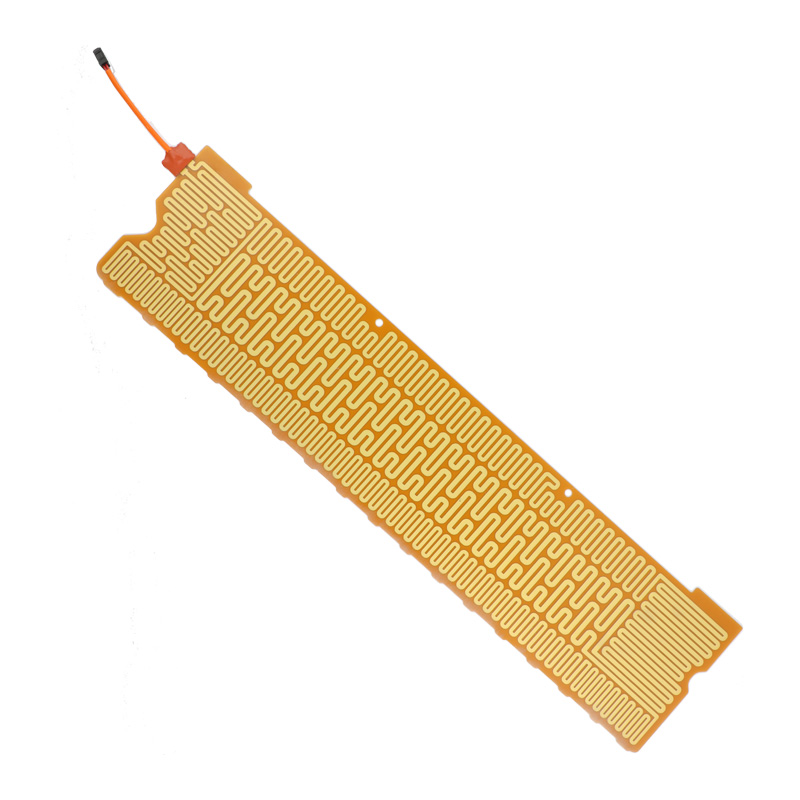

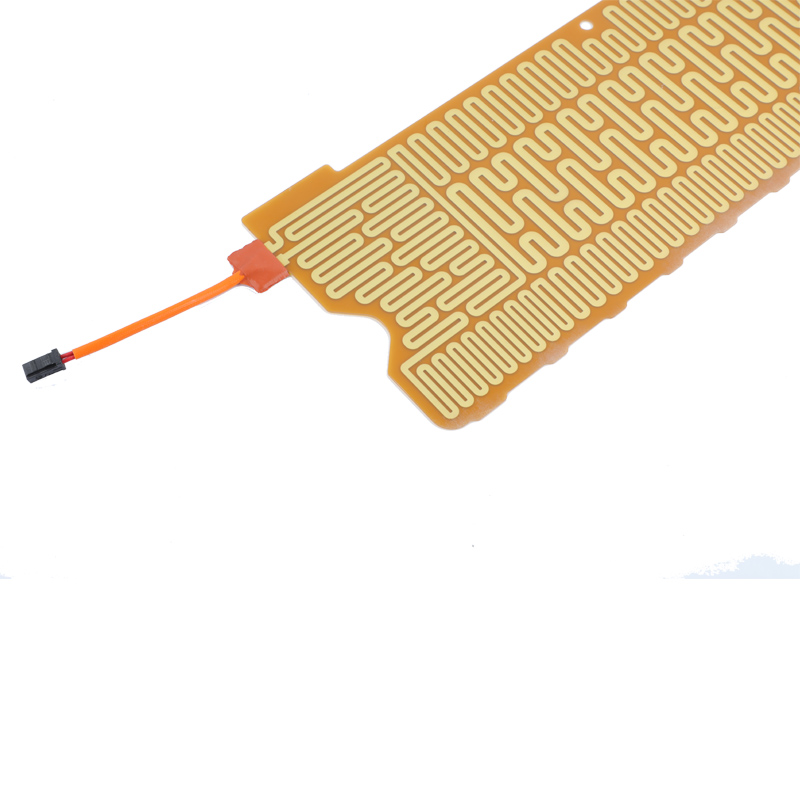

1.Thickness of resistor:0.03-0.1mmT, Thickness of epoxy sheet:0.6-2.5mmT

2.Easy installed with the excellent phisical strength of the epoxy sheet.The product is made of two epoxy plates and resistor laminated by high The product is made of two epoxy plates and resistor laminated by high temperature, so it can be made to various shape, holes can be also reserved for easier installation

3.Can be customized according to shape, size, power and voltage

4.Epoxy heating plate has good chemical corrosion resistance and can be used in humid, corrosive gases and other terrible enviroments

5.Can be easily integrated with thin insulation materials, provide lightweight electric heating elements with insulation layer.

6.Can do adhesive on one side for convenient installation.

7.RoHS,CE,UL compliant

Working Principle

The conductive material inside the electric heating film is usually designed as a resistor with a certain resistance value. According to Joule's law, the resistor produces heat when an electric current passes through it, i.e. Q=I2Rt, where Q is the heat produced, I is the electric current, R is the resistance, and t is the time.

| Operating Voltage | 3.7V-380V AC/DC | Continuous Use Temp | 200℃ (it depends on temperature stability of the adhesive if customer needs adhesive ) |

| Dielectric Breakdown Voltage | ≥2500VAC/MIN | Continuous Use Temp | -50~200℃ |

| Insulation Resistance | ≥100MΩ | Thickness | 0.6-2.5mmT(customizable) |

| Recommended Power Density | 0.1-0.6W/cm2 | Mechanical Compression Strength | 100KG/ cm2 |

| Max Power Density | 2.0W/ cm2 | Pull Force of Guide Line | ≥80N |

| Service Life | 8~15 years | Pull Force of Sordering Point | ≥20N |

What is an Epoxy Heater?

An Epoxy Heater is a heating device that uses an epoxy resin material as a substrate to provide an even heating effect by generating heat through an electric current.

How does an Epoxy Heater work?

An electric current flows through the heating element to generate heat, and the epoxy resin acts as a substrate to provide heat transfer and protection while ensuring even heating.

What are the main advantages of Epoxy Heaters?

The main advantages include excellent resistance to high temperatures, uniform heating, corrosion and chemical resistance.

What are the application areas of Epoxy Heaters?

They are used in industrial heating, laboratory equipment, heating and temperature control of electronic products.

How high can Epoxy Heaters withstand?

Epoxy Heaters can typically withstand temperatures up to 150°C to 200°C, depending on the type and thickness of the epoxy resin.

What is the main material of an Epoxy Heater?

The main material is epoxy resin, combined with a heating element (e.g. resistance wire) to generate heat.

How do I maintain my Epoxy Heater?

Regularly check the electrical connections to avoid overheating the heating plate, keep its surface clean and avoid contact with sharp objects.

What are the safety precautions for Epoxy Heaters?

Avoid overheating, ensure good electrical connections, regularly check the integrity of the heating plate and prevent chemical damage.

How do Epoxy Heaters compare to other heating plates (e.g. silicone heating plates)?

Compared to silicone heating plates, Epoxy Heaters have better heat and chemical resistance, but may lack in flexibility and durability.

What are the applications of Epoxy Heater s in electronics?

Used in electronic products for temperature control systems, heat treatment, installation and testing of heating elements, etc. to ensure the stability and performance of the equipment.

Previous: Mica Heater

Next: Silicone Heating Pad

Contact

No. 1, 1st Road, Mawu Industrial Zone, Qiaoli, Changping Town, Dongguan City, Guangdong Province

Email:

Phone:

+86 136-2001-9955

+86-0769-83488762-8016