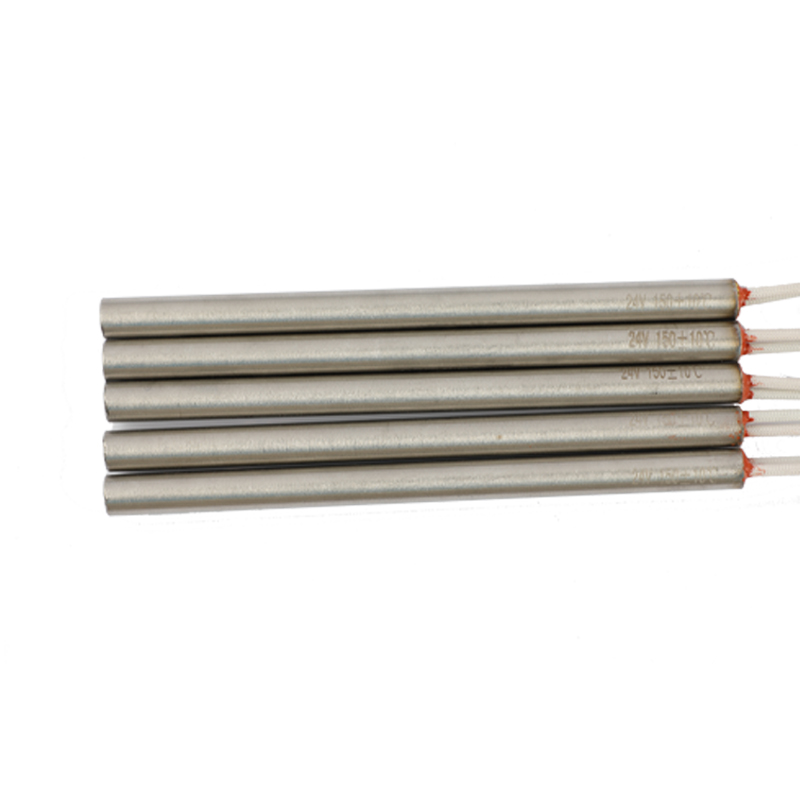

A tubular heating element is a metal tube that encases a heating coil, which generates heat when electricity is passed through it. This design is widely used in heating applications due to its durability and efficiency.

Tubular heating Elements are one of the most widely used types of electric Heating Elements. These versatile components are utilized in a wide range of applications, from industrial heating systems to household appliances. Designed with a metal tube that encases the heating element, they offer durability, efficiency, and precise temperature control.

Whether you're looking for immersion heaters for liquid heating, finned tubular heaters for enhanced heat dissipation, or custom solutions for specific applications, Tubular Heating Elements can meet a variety of needs.

Why Choose Tubular Heating Elements?

Tubular heating elements provide several key advantages:

1.Durability: With a robust metal sheath, they are designed to withstand high temperatures and harsh environments.

2.Efficiency: They ensure rapid heat generation, offering high energy efficiency for both industrial and residential applications.

3.Versatility: Suitable for use in heating liquids, gases, and solids, tubular heaters can be customized to suit specific dimensions, power ratings, and installation requirements.

4.Easy Installation: Available in a range of sizes and configurations, tubular heating elements are easy to install in various heating systems.

Product Specifications & Customization Options

| Parameter | Description |

|---|---|

| Power Range | From 500W to 30kW |

| Voltage Options | 110V, 220V, 380V, 480V |

| Dimensions | Length: 100mm to 3000mm; Outer Diameter: 6mm to 25mm; Inner Diameter: Customizable |

| Material Options | Stainless Steel (SS304, SS316, SS310), Aluminum, Copper, Incoloy, Titanium |

| Sheath Material | Stainless Steel, Inconel, Aluminum, Copper Alloy |

| Operating Temperature Range | -40°C to 800°C |

| Heating Type | Finned Heating Elements, Immersion Heaters, Flexible Heating Elements, Custom Heating Elements |

| Heating Element Type | Nickel-Chromium, Iron-Chromium, Silicon-Carbide, Molybdenum Alloy |

| Installation Type | Flange, Threaded, Bare Tube (Customizable) |

| Power Density | Up to 80W/cm² |

| Corrosion Resistance | Corrosion-resistant coatings available, such as Nickel Plating, Stainless Steel Sheaths, Fluoropolymer Coating |

| Heating Medium | Suitable for heating liquids, air, gases, solids, and more |

| Customization Options | Length, Diameter, Power, Material, Installation Type, Voltage, Surface Coatings, Operating Temperature |

| Certifications | CE, RoHS, UL, ISO9001 |

| Working Environment | Ideal for Industrial, Household, Medical, Food Processing, Plastics & Rubber industries |

| Ingress Protection Rating | IP65, IP67 (for waterproof and dustproof applications) |

| Weight | Typically ranges from 0.5kg to 15kg, depending on size and material |

| Connection Type | Threaded, Plug, Welded Connections (Customizable) |

| Product Lifespan | Up to 10,000 hours, depending on operating conditions and maintenance |

Applications of Tubular Heating Elements

Tubular heating elements are used in diverse industries. Here are some common applications:

1.Industrial Use

Heating Air: Used in air heating systems and furnaces.

Oil & Gas: Applied in industrial heating for oil or gas processing.

Water Heating: Commonly used in boilers and water tanks for consistent water temperature control.

2.Household Appliances

Water Heaters: Essential for domestic hot water systems.

Dishwashers: Used for efficient water heating in dishwashing machines.

Ovens & Toasters: Integral components of kitchen appliances that require precise temperature control.

3.Specialized Applications

Food Processing: Tubular heaters are used in various food production processes to maintain heat.

Plastics & Rubber Industries: Used for heating molds and extruders.

Medical Equipment: Tubular heating elements are used in sterilization units and autoclaves.

FAQ

What is a tubular heating element?

A tubular heating element is a metal tube that encases a heating coil, which generates heat when electricity is passed through it. This design is widely used in heating applications due to its durability and efficiency.

How does a tubular heating element work?

Tubular heating elements work by passing an electric current through a resistive material, which generates heat. This heat is then transferred to the surrounding medium (air, liquid, etc.) via the metal sheath.

What materials are used for tubular heating elements?

Tubular heating elements can be made from a variety of materials, including stainless steel, copper, and aluminum. The choice of material depends on the intended application, such as resistance to corrosion, heat conductivity, and cost considerations.

How do I choose the right tubular heating element?

Consider the application, power requirements, size, and material. For liquid heating, immersion heaters are ideal, while for air heating, finned tubular heaters are more efficient. Custom options are available for unique needs.

Can tubular heating elements be customized?

Yes, we offer custom tubular heating elements that are designed to meet specific power, size, and material requirements. Contact us for more information on custom solutions.

Previous: Diffuser Heater

Contact

No. 1, 1st Road, Mawu Industrial Zone, Qiaoli, Changping Town, Dongguan City, Guangdong Province

Email:

Phone:

+86 136-2001-9955

+86-0769-83488762-8016