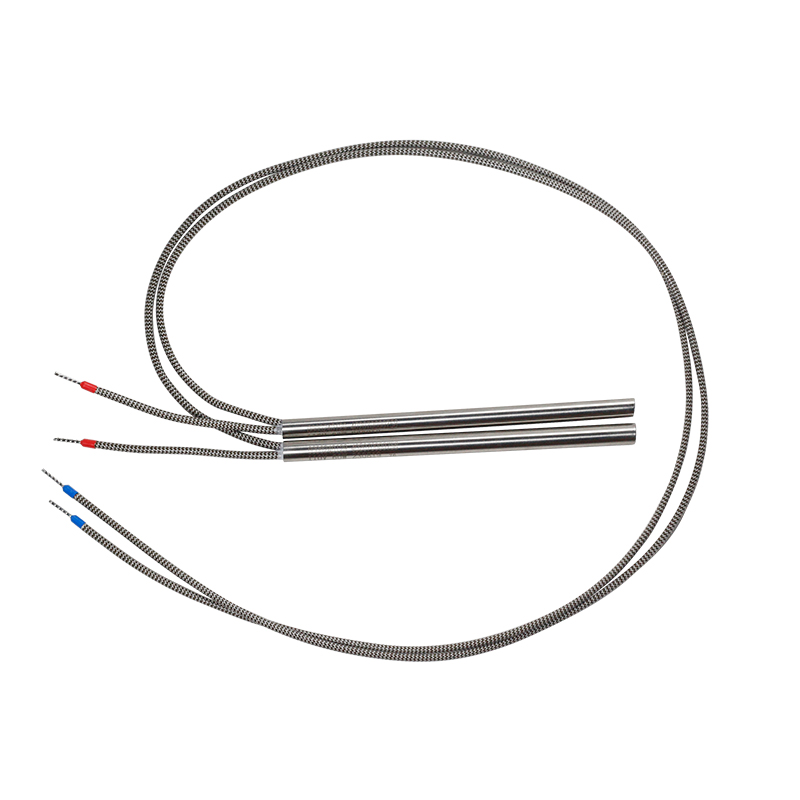

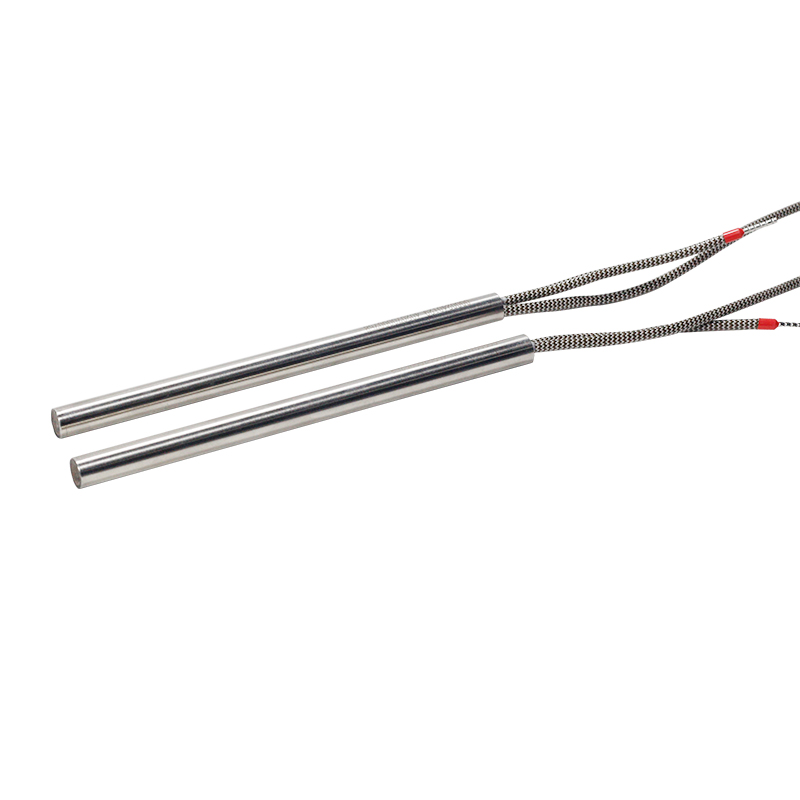

The Tubular Heater is an efficient and reliable heating device that uses precision wound nickel chromium alloy wire as the heating element and is embedded in a high-purity magnesium oxide insulation layer to achieve uniform heat distribution and efficient heat transfer.

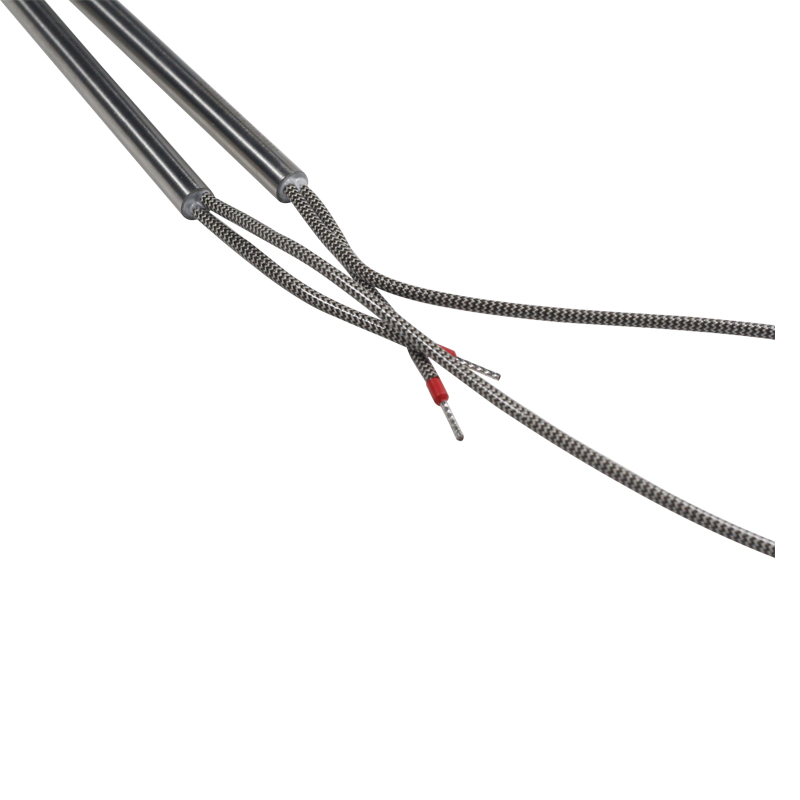

Tubular heaters are typically manufactured from resistance coils placed inside a metal tube and filled with an insulating material (such as magnesium oxide) for safety. The heating coils are placed at an even spacing in the center and are separated from the outer metal sheath by a compacted insulating material that prevents electrical shocks from being transmitted to the outer surface. At the same time, all heat generated is transferred to the process through the outer body for efficient heating.

Product Features

1. High-efficiency heating:Tube heater adopts precision-wound resistance coils, which can transfer heat energy evenly and quickly and improve heating efficiency.

2. Safe and reliable:The insulating materials (such as high-purity magnesium oxide) filled inside not only ensure good insulation, but also enhance the durability and safety of the heater.

3. Flexible customization:Tubular heaters of different diameters, lengths and shapes can be customized to meet various heating needs.

4.Widely used:Suitable for a variety of industrial and commercial fields, such as tumble dryers, dryers, ovens, drying equipment, industrial production lines and so on.

Material Composition

1. Heating element:generally made of high quality electric heating materials such as nickel-chromium alloy to ensure efficient and stable heating performance.

2. Insulating materials:the interior is filled with high purity magnesium oxide and other insulating materials to improve insulation and heat transfer efficiency.

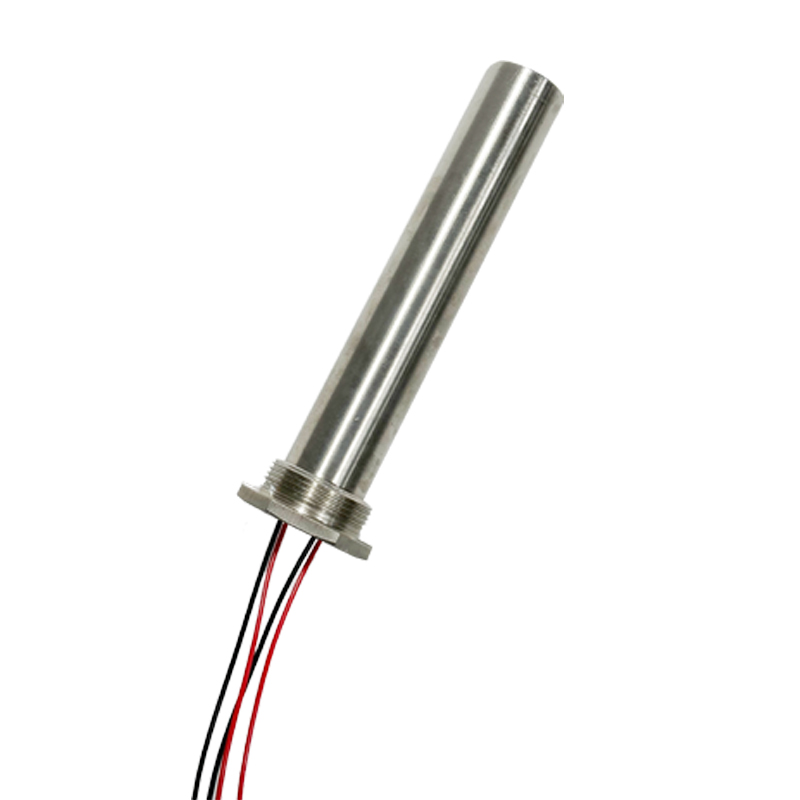

3. Metal tube:the external metal tube is generally made of stainless steel, titanium alloy and other corrosion-resistant, high-temperature-resistant materials to enhance the durability and safety of the heater.

Application Scene

Tube heaters are widely used in many fields because of their high efficiency, safety and reliability:

1. Home appliance field:such as heating tubes in drum washing machines, which are used to provide hot water needed in the washing process.

2. Industrial field:in dryers, ovens, industrial production lines and other equipment, for heating and drying materials.

3. Commercial field:in restaurants, hotels and other places in the kitchen equipment, used for cooking and heating food.

Precautions

1. When using tubular heater, make sure the power supply voltage matches the rated voltage of the heater to avoid over-voltage or under-voltage operation.

2. The heater should be installed in a well-ventilated environment to avoid damage to the heater from humidity and corrosive gases.

3. Regularly check the insulation of the heater and the working condition of the heating element to ensure that the heater is always in good working condition.

| Heating Tube Length | Customizable | Material | 304 Stainless Steel | Rated Voltage | 220V/380V |

| Product Features | Fast nature, high thermal efficiency, long life | Insulation Resistance | >DC1000V200MΩ | Water Pressure Test | 8KG No Leakage |

| Leakage Current | < 0.5 MA | Specifications | Customizable |

Previous: PI Heating Film

Next: Heated Socks

Contact

No. 1, 1st Road, Mawu Industrial Zone, Qiaoli, Changping Town, Dongguan City, Guangdong Province

Email:

Phone:

+86 136-2001-9955

+86-0769-83488762-8016