A Carbon Fiber Heating Element is a type of heating technology that uses carbon fibers as a heating medium. These fibers are known for their high thermal conductivity, durability, and lightweight properties, making them an ideal material for efficient heating solutions. Carbon fiber heating elements are widely used in various applications due to their rapid heating capabilities, energy efficiency, and versatility.

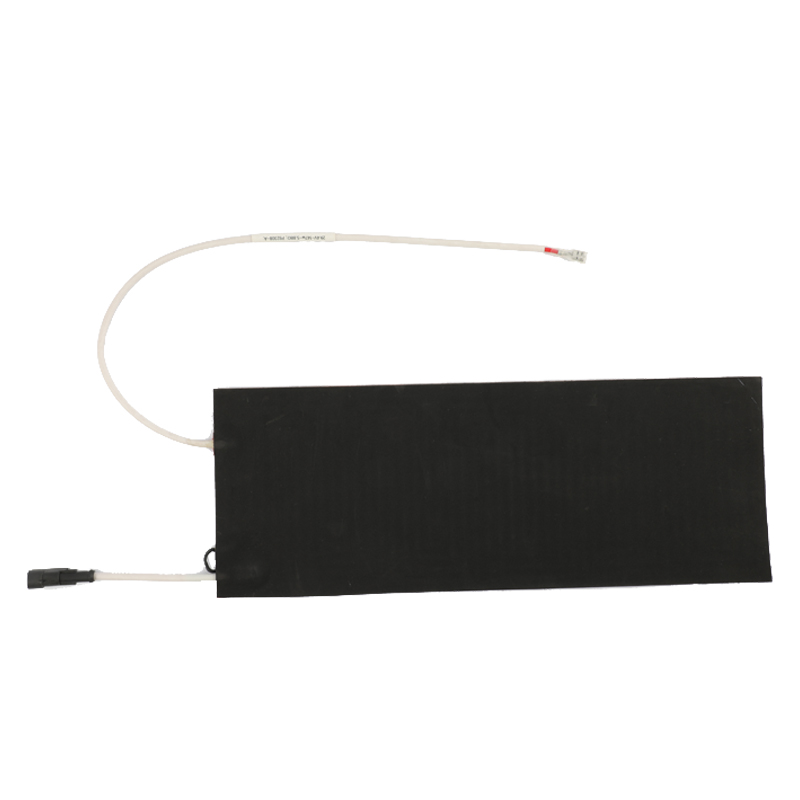

The Carbon Fiber Heating Element is an advanced and highly efficient heating solution that utilizes carbon fiber to generate heat. Carbon fiber, known for its excellent conductivity, strength, and lightweight nature, makes it an ideal material for modern heating applications. This heating element provides fast, uniform heat distribution and is used in a wide variety of applications, from automotive heating systems to floor heating and industrial processes. It is designed to offer long-lasting performance, minimal energy consumption, and a high level of safety.

1.High Efficiency and Rapid Heating:Carbon Fiber Heating Elements provide an outstanding thermal efficiency. The carbon fibers quickly convert electrical energy into heat, allowing for faster warm-up times. This is especially beneficial in applications where quick and even heat is required, such as seat heating in vehicles or underfloor heating in homes and offices.

2.Durability and Longevity:The carbon fiber material used in these heating elements is incredibly durable and can withstand high temperatures without losing its performance. The heating elements have a long operational lifespan, making them a reliable choice for both residential and industrial applications. Their ability to resist wear and tear over time reduces the need for replacements and minimizes maintenance costs.

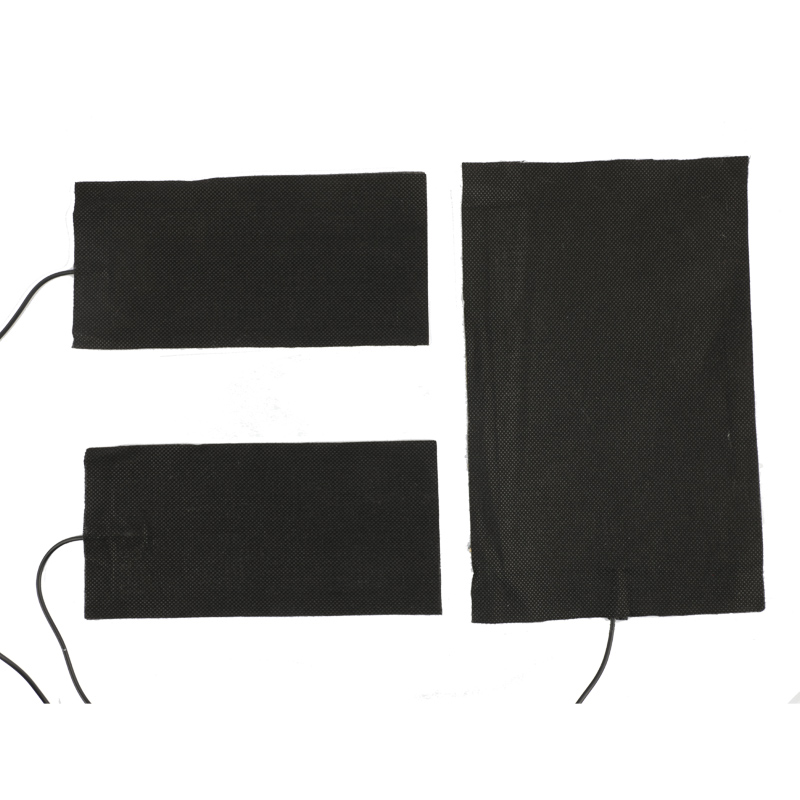

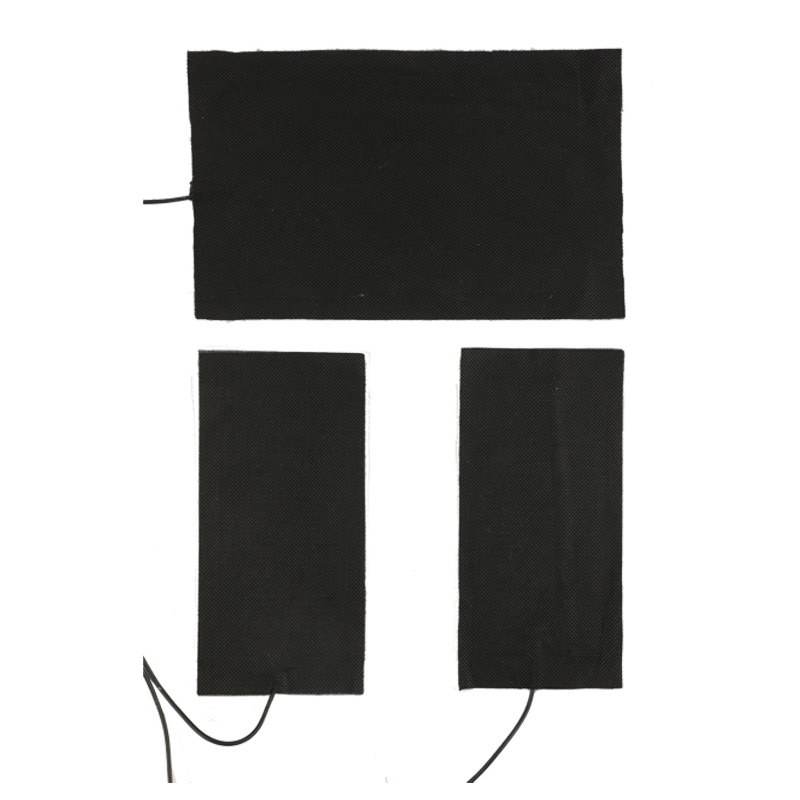

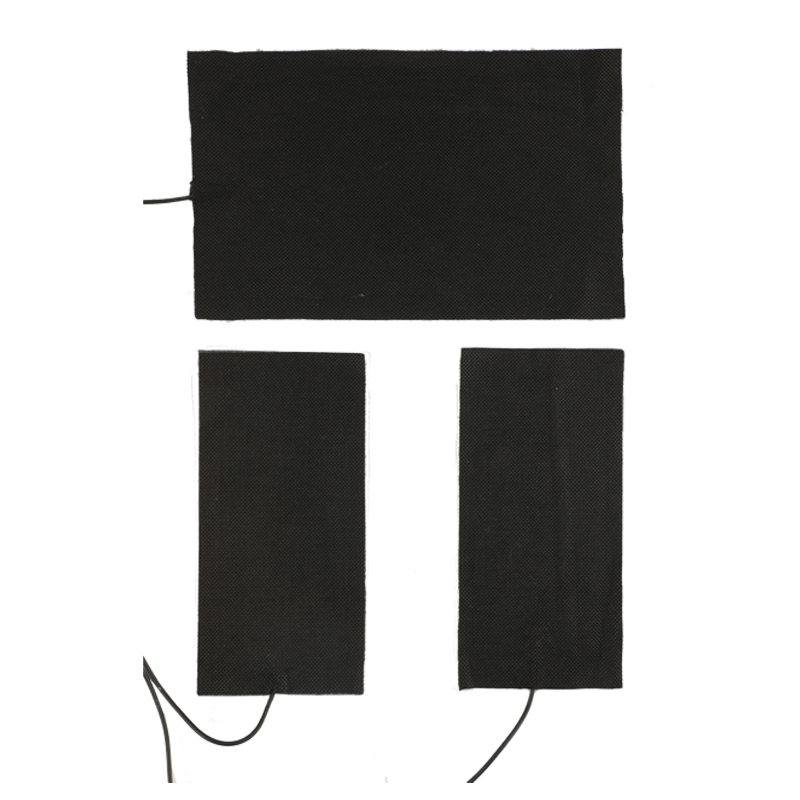

3.Flexibility and Lightweight Design:Carbon fiber is a lightweight material that can be molded into various shapes and sizes, making it highly adaptable to different heating needs. This flexibility allows it to be integrated into spaces that would be difficult for traditional heating elements to fit, such as curved surfaces or narrow gaps. This feature makes Carbon Fiber Heating Elements suitable for a wide range of applications, including complex installations in automotive seating, underfloor heating, and heated mats.

4.Energy Efficiency:Carbon fiber heating elements are highly energy-efficient compared to traditional resistance heating systems. They generate more heat per watt of energy consumed, which reduces energy consumption and ultimately lowers heating costs. This energy efficiency makes them an eco-friendly alternative for heating solutions, contributing to sustainability efforts in both residential and commercial applications.

5.Consistent and Even Heat Distribution:Carbon fiber heating elements offer uniform heat distribution, preventing cold spots and ensuring a consistent temperature across the surface. This feature is particularly important in applications like underfloor heating, where an even temperature is required for comfort, and in automotive seat heating, where it enhances the overall user experience.

6.Safety Features:Safety is a critical concern in any heating system, and carbon fiber heating elements come with several built-in safety features. These include overheat protection, short circuit protection, and self-regulating capabilities to ensure that the heating element does not overheat under normal operating conditions. The carbon fibers are also non-toxic, making them safer than many traditional heating solutions that use potentially harmful materials.

7.Eco-Friendly:The carbon fiber material used in these elements is considered environmentally friendly due to its sustainability. Additionally, carbon fiber heating elements are designed to be more energy-efficient than traditional heating technologies, which reduces the carbon footprint associated with their use.

Carbon Fiber Heating Element product parameters

| Parameter | Specification |

|---|---|

| Material | Carbon Fiber (Customizable with different coatings or insulation options) |

| Voltage | 12V, 24V, 110V, 220V (Customizable to meet specific requirements) |

| Power | 10W to 200W (Customizable based on size and application) |

| Temperature Range | 30°C to 200°C (Customizable for higher or lower temperature ranges) |

| Size/Dimensions | Customizable (tailored to fit specific applications and spaces) |

| Shape | Flat, flexible, and strip forms (Can be designed to various shapes such as round or square) |

| Thickness | 0.2mm to 1mm (Custom thickness options based on heating requirements) |

| Resistance | Low resistance for efficient heat distribution (Can be adjusted for specific applications) |

| Operating Life | 10,000 hours or more (Depending on usage and design) |

| Safety Features | Overheat protection, short-circuit protection (Custom safety features can be integrated) |

| Certification | CE, RoHS, UL (Custom certifications available upon request) |

| Applications | Automotive, medical, industrial, residential heating (Custom applications based on customer needs) |

Carbon Fiber Heating Pad Applications:

1.Automotive Industry:

Seat Heaters: Used in car seats for fast, even warmth.

Defrosting: Carbon fiber heating pads help prevent fog and frost on mirrors and windshields.

2.Residential Heating:

Underfloor Heating: Efficiently heats floors, ideal for homes and offices.

Heated Mats: Portable mats for targeted warmth in cold areas like bathrooms or kitchens.

3.Medical and Therapeutic Uses:

Pain Relief: Provides soothing heat for muscle pain, joint stiffness, and arthritis.

Physical Therapy: Aids recovery by promoting blood circulation.

4.Industrial Applications:

Machinery Heating: Used to maintain temperatures in industrial equipment, such as plastic molding or drying.

5.Sports and Outdoor Gear:

Heated Clothing: Integrated into jackets, gloves, and insoles for warmth in cold environments.

Advantages of Carbon Fiber Thermal Elements:

1.Efficient Heat Distribution:Carbon fiber thermal elements provide even and consistent heat distribution across surfaces, ensuring uniform heating without hot spots, which is essential for various applications like underfloor heating or seat warmers.

2.Fast Heating Time:These elements heat up quickly, allowing for rapid temperature increases and providing immediate warmth, making them ideal for automotive, medical, and residential applications.

3.Durability:Carbon fiber is highly durable and resistant to wear, heat, and corrosion. This makes carbon fiber thermal elements long-lasting, even in demanding environments such as automotive or industrial settings.

4.Energy Efficiency:Carbon fiber thermal elements are energy-efficient, requiring less energy to produce heat compared to traditional heating methods, helping to reduce overall energy consumption and lower operating costs.

5.Lightweight:Carbon fiber is lightweight yet strong, which makes these thermal elements easy to install in a variety of applications, from automotive seating to clothing and medical devices, without adding significant weight.

6.Flexibility:Carbon fiber thermal elements are flexible and can be customized to fit various shapes and sizes, making them ideal for integration into products like heated clothing, mats, or industrial machinery.

7.Precise Temperature Control:These elements allow for precise temperature regulation, ensuring that the desired heat level is maintained consistently. This is crucial for applications like therapeutic devices or precise industrial processes.

8.Safety:Carbon fiber thermal elements typically come with built-in safety features, such as overheat protection, which helps prevent damage and ensures safe operation in a variety of environments.

9.Environmentally Friendly:Since carbon fiber is a long-lasting material, it reduces the need for frequent replacements, contributing to sustainability and reducing waste.

10.Versatility:Carbon fiber thermal elements can be used in a wide range of applications, from heating automotive seats and medical therapeutic devices to providing warmth in outdoor clothing and industrial machinery.

FAQ

What is a Carbon Fiber Heating Element?

A carbon fiber heating element is a device that uses carbon fiber to generate and distribute heat efficiently. It is commonly used in applications such as automotive seat heaters, underfloor heating systems, and therapeutic heating pads.

What are the advantages of using Carbon Fiber for heating elements?

Carbon fiber heating elements offer fast heating, energy efficiency, long-lasting durability, and precise temperature control. They are also lightweight and flexible, making them suitable for a variety of applications.

What are the typical applications for Carbon Fiber Heating Elements?

Carbon fiber heating elements are widely used in automotive seat heating, medical and therapeutic devices, underfloor heating systems, heated mats, and even in clothing for outdoor use.

Can Carbon Fiber Heating Elements be customized?

Yes, carbon fiber heating elements can be customized in terms of size, shape, voltage, power, temperature range, and other specifications to suit specific applications.

What temperature range can Carbon Fiber Heating Elements operate in?

Carbon fiber heating elements typically operate within a temperature range of 30°C to 200°C, though custom models can be designed for higher or lower temperature ranges based on application needs.

What makes Carbon Fiber Heating Elements energy-efficient?

The excellent thermal conductivity of carbon fiber allows for rapid heat distribution with less energy consumption compared to traditional heating methods, making carbon fiber elements highly energy-efficient.

Are Carbon Fiber Heating Elements safe to use?

Yes, carbon fiber heating elements are generally safe, with built-in features such as overheat protection, short-circuit protection, and safe insulation to ensure secure operation.

How long do Carbon Fiber Heating Elements last?

Carbon fiber heating elements can last for over 10,000 hours, depending on usage and maintenance, making them a long-lasting option for various heating applications.

Can Carbon Fiber Heating Elements be integrated into flexible materials?

Yes, one of the key advantages of carbon fiber heating elements is their flexibility, allowing them to be integrated into a variety of flexible materials, such as heated clothing, mats, and automotive seat covers.

Are Carbon Fiber Heating Elements environmentally friendly?

Carbon fiber heating elements contribute to sustainability by being durable and energy-efficient, reducing the need for frequent replacements and minimizing energy consumption.

Previous: PTC Element

Next: Silicone Heat Tape

Contact

No. 1, 1st Road, Mawu Industrial Zone, Qiaoli, Changping Town, Dongguan City, Guangdong Province

Email:

Phone:

+86 136-2001-9955

+86-0769-83488762-8016