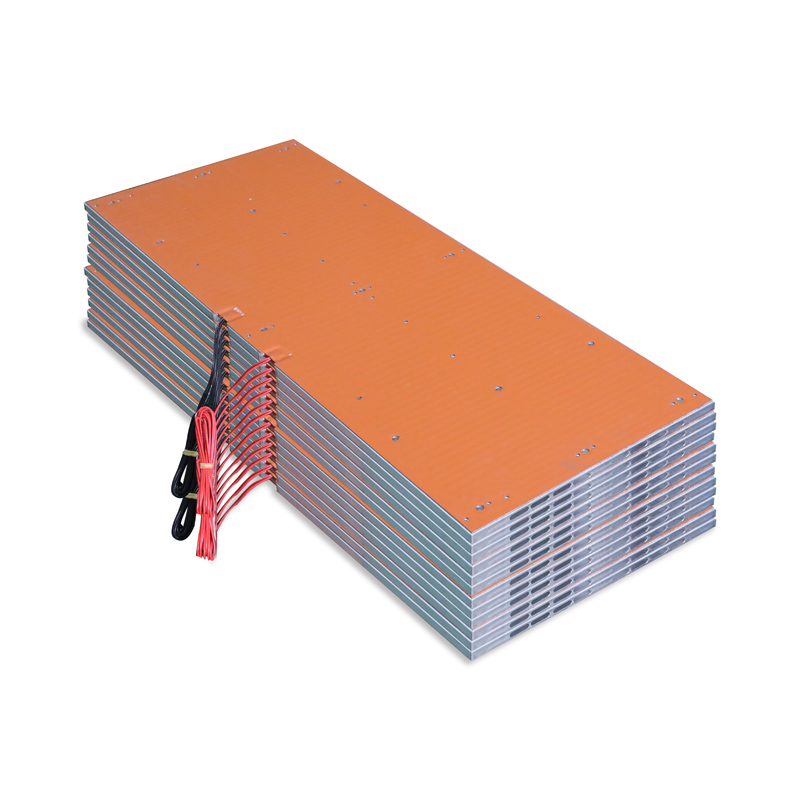

Aluminium Heat Plate is an efficient, durable and versatile thermal management solution for a wide range of industrial and electronic devices that require uniform heating and efficient heat dissipation. With its excellent thermal conductivity, light weight and strength, and customization options, Aluminium Heat Plate provides reliable thermal management and heat dissipation for a wide range of applications. Whether in electronic equipment, industrial heating equipment, home appliances or the automotive industry, Aluminium Heat Plate is an ideal choice.

Aluminium Heat Plate is a widely used product in the field of heating and thermal management, which is mainly used to distribute heat evenly to the surface of heating elements or equipment. It is made of aluminum alloy material with good thermal conductivity and durability.

Product Features

1.Excellent thermal conductivity:Aluminum alloy material has high thermal conductivity, which can quickly and evenly disperse heat, reduce hot and cold spots, and ensure the consistency and efficiency of heating effect.

2. Lightweight and High Strength:Aluminum alloy has low density but high strength, making Aluminium Heat Plate lightweight and strong, easy to install and operate, while withstanding high temperature and mechanical stress.

3. Corrosion resistance:Aluminum alloy surfaces are usually anodized to effectively resist corrosion and oxidation, extending product life and adapting to a variety of harsh environments.

4. Excellent processability:Aluminum alloy is easy to process and form, able to manufacture various sizes and shapes of hot plates according to specific needs to meet the requirements of different applications.

5. High heat dissipation efficiency:Aluminum Heat Plate has excellent heat dissipation ability, which can quickly transfer heat from the heating source to the surface of the equipment and enhance the overall thermal efficiency of the system.

Lightweight features for easy installation and operation

1. Electronic equipment heat dissipation:Aluminium Heat Plate is used in the heat dissipation management of electronic equipment, such as computer processors, LED lighting equipment, power modules, etc., to ensure that the equipment operates stably within the safe temperature range.

2. Industrial heating equipment:In plastic molding machines, injection molding machines, extruders and other industrial equipment, used to evenly distribute heat to the surface of the equipment, optimize heating efficiency and product quality.

3. Heat exchanger:Used in heat exchangers to effectively transfer heat from one medium to another and improve heat exchange efficiency.

4. Automotive industry:In automotive engines and other components, used for thermal management and heat dissipation, to ensure that the engine and other critical components work at the optimal temperature.

5. Home appliances:such as induction cooktops, ovens and other home appliances, used as heating elements or heat sinks to enhance product performance and service life.

6. Solar water heaters:In solar water heaters, as part of the heat exchange plate, the sunlight is utilized to heat the water in the tank, improving the efficiency of the water heater.

Installation and Maintenance

1.Installation:Aluminium Heat Plate is usually fixed on the equipment by bolts, clamps or welding, etc. When installing, it is necessary to make sure that the contact surface is flat in order to realize the best heat conduction effect.

2. Maintenance:Regularly check the surface of the Heat Plate to see if there is any accumulation of dust or dirt, and clean it in time to maintain good heat dissipation performance. Check whether the fixing parts are firm to prevent the hot plate from shifting or poor contact due to vibration or loosening.

3. Operating Precautions:Avoid exposing the hot plate directly to corrosive chemicals to prevent surface oxidation or damage. When operating at high temperatures, ensure that the surrounding environment is well ventilated to prevent overheating that could lead to equipment failure.

Packaging and Transportation

1.Packing:Each Aluminium Heat Plate has passed strict quality inspection and is shipped with sturdy packing materials to ensure that it will not be damaged during transportation.

2.Transportation:Usually shipped by sea, air or express, according to the order quantity and delivery time requirements to choose the most suitable mode of transportation.

What is Aluminium Heat Plate?

Aluminium Heat Plate is a kind of heating plate made of aluminum alloy with excellent thermal conductivity and heat dissipation performance, used to distribute heat evenly to the heating element or equipment surface, widely used in heating and thermal management field.

What is the main material of Aluminium Heat Plate?

Aluminium Heat Plate is mainly made of aluminum alloy material (such as 6061, 5052, etc.), which has excellent thermal conductivity and corrosion resistance.

What is the maximum working temperature of Aluminium Heat Plate?

Aluminium Heat Plate is typically capable of stable operation in the temperature range of 200°C - 300°C. The exact operating temperature depends on the aluminum alloy specification. The exact operating temperature depends on the specification of the aluminum alloy and the surface treatment.

What is the typical thickness range of Aluminium Heat Plate?

Aluminium Heat Plate thicknesses typically range from 2 - 10 mm. Depending on the application, different thicknesses can be customized to suit specific heat dissipation requirements.

What are the main applications for Aluminium Heat Plate?

Aluminium Heat Plate is mainly used in electronic equipment cooling, industrial heating equipment, heat exchangers, automotive industry, household appliances and solar water heaters.

How can Aluminium Heat Plate be customized?

Aluminium Heat Plate can be customized in terms of size, shape, thickness, surface treatment (e.g. anodized, plated, painted) and accessories (e.g. fixing brackets, fixing holes for heating elements) according to customer requirements.

How to install Aluminium Heat Plate?

Aluminium Heat Plates are usually bolted, clamped or welded to the equipment. When mounting, it is necessary to ensure that the contact surface is flat for optimal heat transfer.

What are the surface treatments for Aluminium Heat Plates?

The surface treatment of Aluminium Heat Plate includes anodizing, plating, spraying, etc. These treatments can improve its corrosion resistance and aesthetics to adapt to different working environments.

What are the maintenance requirements for Aluminum Heat Plate?

Maintenance requires regular inspection of the surface of the heat plate for dust or dirt accumulation, and timely cleaning to maintain good heat dissipation performance. Also check whether the fixing parts are firm to avoid shifting or poor contact due to vibration or loosening.

How to choose the right Aluminum Heat Plate?

Selecting the right Aluminum Heat Plate requires consideration of the following factors: operating temperature, thermal conductivity, size and shape, thickness, surface finish requirements, and specific application scenarios. Based on these factors, the most appropriate type of aluminum alloy and finish should be selected to ensure that it meets the needs of the application.

Previous: Heating Wire

Next: Mica Plate Heater

Contact

No. 1, 1st Road, Mawu Industrial Zone, Qiaoli, Changping Town, Dongguan City, Guangdong Province

Email:

Phone:

+86 136-2001-9955

+86-0769-83488762-8016